DDG-1000 Zumwalt: Stealth warship

U.S. Navy navigates radar transparency, cost and weight challenges with composite superstructure design.

Share

Engineering Challenge:

Meet fire-retardance/fire containment requirements, reduce radar signature and weight, yet control cost during construction of four upper decks of the destroyer’s deckhouse superstructure.

Design Solution:

Use primarily flat composite sandwich panels to simplify tooling, and core them with balsa, which burns more slowly than foam and better insulates the opposite sandwich skin from heat, optimizing fire safety.

Historically, the U.S. Navy has lagged behind the other military branches in wide-scale use of composites in critical combat hardware — specifically, its ships. This, however, is about to change with the building of the first of a new family of advanced, multimission destroyers, the DDG-1000 Zumwalt class.

The Zumwalt class had its genesis in 2001, when the Navy announced the DD(X) program would supersede the DD 21 project, which was to replace Oliver Perry-class frigates and Spruance-class destroyers with 32 new multimission destroyers by 2012. Although the DD(X) plan originally called for 8 to 12 “advanced technology surface combatants,” the Navy renamed it DDG-1000 and trimmed it to three ships in 2008. Unlike traditional destroyers, which primarily engage in offshore anti-air and undersea warfare, the new ships also were to provide support for land attack and ground forces.

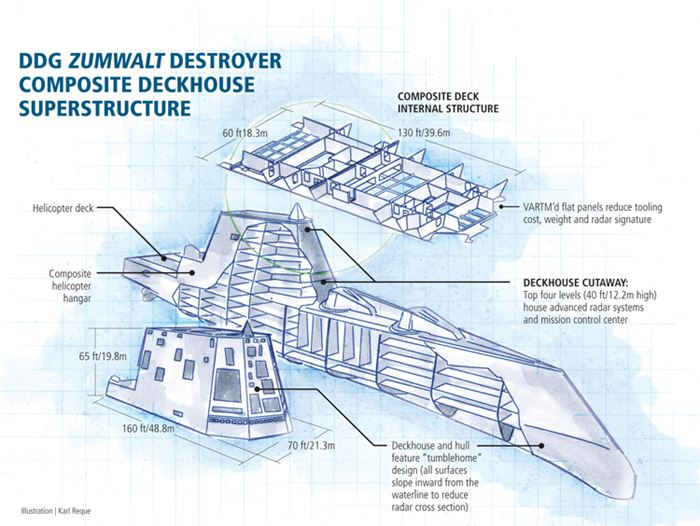

The ship design includes an upper-section deckhouse (superstructure) constructed with panels and beams made of carbon fiber/vinyl ester skins and balsa and/or foam cores. The ship also features a composite helicopter hanger built of the same material, as well as an integrated composite ballistic screen. The composite deckhouse for the first ship, the Zumwalt, is in progress at Northrop Grumman Shipbuilding (NGSB) facility in Gulfport, Miss., under the supervision of the ship’s prime general contractor, General Dynamics (Bath Iron Works, Bath, Maine).

Charting a course to composites

The Navy first looked into expanding the use of composites in its fleet of large capital ships about 15 years ago. Until that time, glass fiber-reinforced polymers had been used only in the construction of small river patrol boats, minesweepers and, in limited quantity, for various small components and hardware on larger ships. The first large-scale application involved the Advanced Enclosed Mast Sensor (AEMS) system aboard the USS San Antonio (LPD 17), the first of a new class of landing platform dock ships. Each incorporates two 80-ft tall by 35-ft diameter (24.4m by 10.7m) AEMS masts, made from glass-reinforced vinyl ester sandwich panels, with cores of balsa and/or foam. This project set the stage for the use of composites in the DDG-1000 program.Because the ships will tactically assist landing operations, stealth has been a paramount consideration in the ship’s design. For that reason, Zumwalt has a “tumblehome” hull shape — that is, a design in which the hull slopes inward from above the waterline. Such a shape significantly reduces the ship’s radar cross section. Similar design requirements are specified for the ship’s integrated deckhouse. Official Naval Technology documentation describes the deckhouse as “fully EMC shielded with reduced infrared and radar signatures.” The choice of an all-composite superstructure has helped engineers fulfill those conditions, as well as reduce topside weight and total ship tonnage.

The DDG-1000 project’s “gold team” — NGSB and a variety of subcontractors — evaluated a multitude of material combinations, generating more than 6,000 individual test articles over a period of 10 years. Ultimately, the team settled on a sandwich construction, featuring balsa supplied by Alcan Baltek Corp. (Northvale, N.J.) between skins made from Toray T700 12K FOE carbon fiber, supplied by Toray Carbon Fiber America Inc. (Flower Mound, Texas), and 510A vinyl ester resin from Ashland Inc. (Dublin, Ohio).

Carbon fiber bested glass in the trials, says Barry Heaps, NGSB program manager/director DDG-1000 Deckhouse, because “the structural load requirements for the … deckhouse are significantly higher than those for LPD masts.”

Sigmatex Inc. (Benicia, Calif.) wove the T700 fiber into three different types of fabric: a noncrimp ±45° stitched material at a weight of 410 g/m², a bonded unidirectional material at 680 g/m², and a plain-weave 0°/90° fabric at 300 g/m².

“The T700 fiber was chosen because it provided us with the required stiffness in whatever fabric we selected it in,” says Heaps, noting that the combination of materials yielded the desired strength-to-weight ratio and the necessary panel flatness the team needed to successfully construct the deckhouse.

Alcan Baltek supplies balsa in three different densities: 10 lb/ft³, 15 lb/ft³ and 20 lb/ft³, but for panels that require unusually high shear strength, a 33 lb/ft³ syntactic foam is used as the core, according to a Naval spokesperson.

Joe Pantalone, Alcan Baltek’s market manager, reports that Navy engineers selected balsa core because they learned early in their evaluation of composite materials that “the mechanical properties of balsa as a core material compared to its cost are significantly better than any other material.” Pantalone likens balsa, with its cellular structure of cellulose fiber in a lignin matrix, to the fiber/resin makeup of a composite. He reports that Navy tests showed that a balsa-core sandwich contained fire spread better than those cored with foam or honeycomb. “Balsa doesn’t burn very well at all,” says Pantalone. “Rather, it chars slowly. So it does a better job of insulating the opposite-side skin, unlike foam, which softens and transfers heat more readily.” Unlike honeycomb core, wood cells are terminal or closed in the thickness direction, he adds, so balsa requires no intermediate barrier material to prevent ingress of resin during infusion, keeping cost down and ensuring that the balsa core retains its low weight.

Project size dictates simple tooling

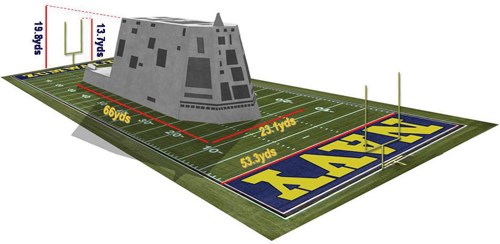

The dimensions of the DDG-1000’s seven-level deckhouse are approximately 160 ft long by 70 ft wide by 65 ft high (48.8m by 21.3m by 19.8m). The first three levels are constructed of steel, while the upper four levels, or superstructure, are being made of the balsa-cored carbon/vinyl ester sandwich panels. The deckhouse superstructure — approximately 130 ft long by 60 ft wide by 40 ft high (39.6m by 18.3m by 12.2m) — contains advanced radar systems, and a mission planning/control center.For the most part, the composite panels are flat, says Heaps, a design outcome dictated in part by a desire to keep down tooling costs. “The reason we wanted flat panels is that we had previously seen, going back to the LPD masts, lots of shapes and lots of molds [that] have a limited lifetime and are very expensive,” Heaps reports. “So to make the program more cost-effective, we took the approach of using flat panels, where most of the tooling is flat, thus requiring fewer specially designed tools. There are exceptions to this — for example, beams, which have depth and shape.”

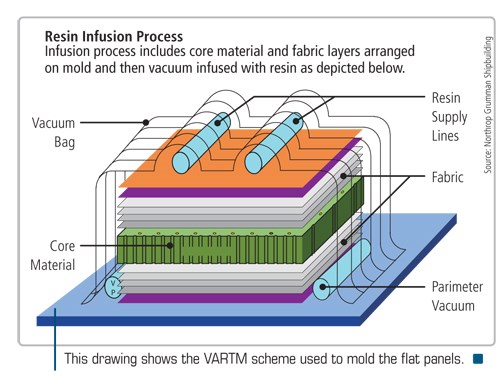

The performance of the carbon-fiber fabric/resin system was confirmed by the construction of a 1/3-scale model of the deckhouse, which then was tested at China Lake Naval Air Weapons Station in California’s Mojave desert. Construction of the first full-size superstructure is now under way. Here, the project is breaking new ground by molding some of the largest panels ever built by the vacuum-assisted resin transfer molding (VARTM) process. Panels as large as 120 ft long by 60 ft wide (36.6m by 18.3m) are in process at the NGSB Gulfport facility, and can take up to 12 hours to infuse with resin.

Tools are typically coated with a tooling-release agent prior to the lay down of the external reinforcing fabrics, balsa core and interior fabrics. A woven glass cloth peel ply also is usually placed on the tool or external side of the panel. The cloth is peeled off after infusion and cure, providing a clean, bondable surface for secondary bonding and assembly. A stainless steel mesh also is integrated into the fabric on the external skin, providing electromagnetic interference (EMI) shielding and a lightning ground in the otherwise nonconductive panels.

The skins, which can comprise several different types of fabric, are approximately 0.125 inch/3.2 mm thick, while the balsa cores range from 2 to 3 inches (50.8 mm to 76.2 mm) thick, depending on structural and functional requirements. For example, the noncrimp, ±45° stitched fabric is used in combination with the 0°/90° plain-weave fabric in a typical wall panel to create a “quasi-isotropic” effect, which provides roughly uniform stiffness and strength in all directions. “The reason we took a quasi-isotropic approach in the design for these panels is that it gives us a high-strength-to-low-weight ratio that’s critical,” says Walter Whitehead, NGSB’s manager, composites engineering.

The much heavier, bonded unidirectional fabric is used in areas and structures where higher stiffness is needed in a single direction. “We have some very large beams that support a large open area in the helicopter hanger and those beams are made with the unidirectional material,” says Heaps, noting that the heavier material is much more difficult to infuse. “It’s pretty much mix-and-match,” says Heaps of the fabric selection. “There may be more of one type of fabric than another, taking into account both structural requirements and ease of infusion.” Heaps reports that if the team needs to make a panel thinner in an area but add or retain stiffness, the panel can be reinforced by a beam made of the unidirectional fabric.

The infused and cured panels are assembled by means of laminate step-downs or “scarfs” that facilitate vertical-to-vertical and horizontal-to-horizontal bonds, with wedge blocks between vertical and horizontal panels. Structural putty is used to affix the wedge block between the 90°angle formed by the panels, and the block is wrapped in carbon fiber fabric and infused with resin.

A mid-course correction?

At press time, the DDG-1000 Zumwalt was 15 percent complete. Three of the four levels of the composite deckhouse were in assembly and workers had begun fabrication of the exterior decks and side shelves of the hangar unit.

Although VARTM is being used exclusively for the sandwich panels on the Zumwalt, Heaps says the team is considering some pultruded sandwich panels in the build of the second ship. “Pultrusions have the potential to be cheaper, but there’s still some testing and work to be done to implement them in a deckhouse,” says Heaps.

Related Content

US Air Force selects Integris Composites ballistic body armor

Cratus Wave armor is thin, lightweight and reduces heat stress, providing buoyant personal protection for the 582nd Helicopter Group.

Read MoreOrbital Composites wins AFWERX award for Starfighter drone fleet

Under the TACFI contract, Orbital is implementing the AMCM process to build 3D printed composite multi-mission UAS aircraft, surpassing $10 million in government awards.

Read MoreMilliken & Co. partners with MMI Textiles to offer Tegris thermoplastic

The commercial market partnership enables easier access to the Tegris thermoplastic composite fabric for defense customers in the quantities that they require.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More