Fiber reinforcement forms

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application.

Roving and tow. Roving is the simplest and most common form of glass fiber. It can be chopped, woven or otherwise processed to create secondary fiber forms for composite manufacturing, such as mats, woven fabrics, braids, knitted fabrics and hybrid fabrics. Rovings are supplied by weight, with a specified filament diameter. The term yield is commonly used to indicate the number of yards in each pound of glass fiber rovings. Similarly, tow is the basic form of carbon fiber. Typical aerospace-grade tow size ranges from 1K to 24K (K = 1,000, so 12K indicates that the tow contains 12,000 carbon filaments). PAN- and pitch-based 12K carbon fibers are available with a moderate (33-35 Msi), intermediate (40-50 Msi), high (50-70 Msi) and ultrahigh (70-140 Msi) modulus. (Modulus is the mathematical value that describes the stiffness of a material by measuring its deflection or change in length under loading.) Newer heavy-tow carbon fibers, sometimes referred to as commercial-grade fibers, with 48K-320K filament counts, are available at a lower cost than aerospace-grade fibers. They typically have a 33-35 Msi modulus and 550-ksi tensile strength and are used when fast part build-up is required, most commonly in recreational, industrial, construction and automotive markets. Heavy-tow fibers exhibit properties that can approach those of aerospace-grade fibers but can be manufactured at a lower cost because of precursor and processing differences. (Carbon fiber's high cost and historically significant fluctuations in its supply and demand, generate perennially high interest in the composites industry about the state of the global carbon fiber market, a subject treated in "Supply and demand: Advanced fibers," under "Editor's Picks," at right.)

A potentially significant recent variation is carbon fiber tow that features aligned discontinuous fibers. These tows are created in special processes that either apply tension to carbon tow at differential speeds, which causes random breakage of individual filaments, or otherwise cut or separate individual carbon filaments such that the filament beginnings and ends are staggered and their relative lengths are roughly uniform so that they remain aligned and the tow maintains its integrity. The breaks permit the filaments to shift position in relation to adjacent filaments with greater independence, making the tow more formable and giving it the ability to stretch under load, with greater strength properties than chopped, random fibers. Fiber forms made from aligned discontinuous tows (see “Mats,” below) are more drapable; that is, they are more pliable and, therefore, conform more easily to curved tool surfaces than fiber forms made from standard tow.

Mats are nonwoven fabrics made from fibers that are held together by a chemical binder. They come in two distinct forms: chopped and continuous strand. Chopped mats contain randomly distributed fibers cut to lengths that typically range from 38 mm to 63.5 mm. Continuous-strand mat is formed from swirls of continuous fiber strands. Because their fibers are randomly oriented, mats are isotropic — they possess equal strength in all directions. Chopped-strand mats provide low-cost reinforcement primarily in hand layup, continuous laminating and some closed molding applications. Inherently stronger continuous-strand mat is used primarily in compression molding, resin transfer molding and pultrusion applications and in the fabrication of preforms and stampable thermoplastics. Certain continuous-strand mats used for pultrusion and needled mats used for sheet molding eliminate the need for creel storage and chopping.

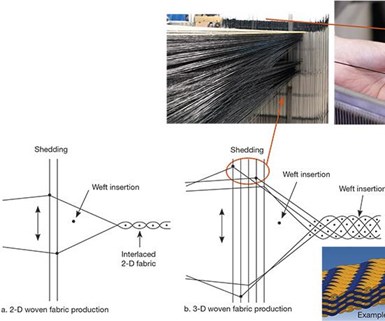

Woven fabrics are made on looms in a variety of weights, weaves and widths. Pictured are Jacquard looms at Albany Engineered Composites’ (AEC, Rochester, NH, US) that facilitate manufacture of three-dimensional preforms (that is, fiber reinforcements that are interlocked not only in the x/y directions, but the z-direction (through-thickness). These mass-produced materials shorten the time necessary to develop prepregs and dry fabrics that can be layed up quickly by fabricators. Source: Albany International Corp.

Woven fabrics are made on looms in a variety of weights, weaves and widths. Wovens are bidirectional, providing good strength in the directions of yarn or roving axial orientation (0º/90º), and they facilitate fast composite fabrication. However, the tensile strength of woven fabrics is compromised to some degree because fibers are crimped as they pass over and under one another during the weaving process. Under tensile loading, these fibers tend to straighten, causing stress within the matrix system.

Multilayer fabrics have been woven on traditional 2-D weaving looms for some time. These fabrics are produced by splitting the warp fibers (oriented in the direction of fabric production) to create multiple sheds (spaces through which the weft or filling fibers are inserted at right angles to the warp). If the warp ends are moved up or down during weaving (in Jacquard looms this is done using heddles (pictured above), then the fabric can be made to consist of several layers stacked vertically. Warp ends can be interlaced with fill fibers in the adjacent layer to produce layer-to-layer locked fabrics, or they can be interlaced with fill fibers in the top and bottom layers to create angle-interlocked fabrics. Source: Albany International Corp.

Several different types of weaving are used for bidirectional fabrics. In a plain weave, each fill yarn (i.e., yarn oriented at right angles to the fabric length) alternately crosses over and under each warp yarn (the lengthwise yarn). Other weaves, such as harness, satin and basket weave, allow the yarn or roving to cross over and under multiple warp fibers (e.g., over two, under two). These weaves tend to be more drapable than plain weaves.

Woven roving is relatively thick and used for heavy reinforcement, especially in hand layup operations and tooling applications. Due to its relatively coarse weave, woven roving wets out quickly and is relatively inexpensive. Exceptionally fine woven fiberglass fabrics, however, can be produced for applications such as reinforced printed circuit boards.

Hybrid fabrics can be constructed with varying fiber types, strand compositions and fabric types. For example, high-strength strands of S-glass or small-diameter filaments may be used in the warp direction, while less-costly strands compose the fill. A hybrid also can be created by stitching woven fabric and nonwoven mat together.

Multiaxials are nonwoven fabrics made with unidirectional fiber layers stacked in different orientations and held together by through-the-thickness stitching, knitting or a chemical binder. The proportion of yarn in any direction can be selected at will. In multiaxial fabrics, the fiber crimp associated with woven fabrics is avoided because the fibers lie on top of each other, rather than crossing over and under. This makes better use of the fibers’ inherent strength and creates a fabric that is more pliable than a woven fabric of similar weight. Super-heavyweight nonwovens are available (up to 200 oz/yd²) and can significantly reduce the number of plies required for a layup, making fabrication more cost-effective, especially for large industrial structures. High interest in noncrimp multiaxials has spurred considerable growth in this reinforcement category.

Braided fabrics are continuously woven on the bias and have at least one axial yarn that is not crimped in the weaving process. The braid’s strength comes from intertwining three or more yarns without twisting any two yarns around each other. This unique architecture offers, typically, greater strength-to-weight than wovens. It also has natural conformability, which makes braid especially suited for production of sleeves and preforms (see “Preforms,” below) because it readily accepts the shape of the part that it is reinforcing, thereby obviating the need for cutting, stitching or manipulation of fiber placement. Braids also are available in flat fabric form. These can be produced with a triaxial architecture, with fibers oriented at 0°, +60°, -60° within one layer. This quasi-isotropic architecture within a single layer of braided fabric can eliminate problems associated with the layering of multiple 0˚, +45˚, -45˚ and 90˚ fabrics. Furthermore, the propensity for delamination (separation of fiber layers) is reduced dramatically with quasi-isotropic braided fabric. Its 0°, +60°, -60° architecture gives the fabric the same mechanical properties in every direction, so the possibility for a mismatch in stiffness between layers is eliminated.

In both sleeve and flat fabric form, the fibers are continuous and mechanically interlocked. Because all the fibers in the structure are involved in a loading event, the load is evenly distributed throughout the structure. Therefore, braid can absorb a great deal of energy as it fails. Braid’s impact resistance, damage tolerance and fatigue performance have attracted composite manufacturers in a variety of applications, ranging from hockey sticks to jet engine fan cases.

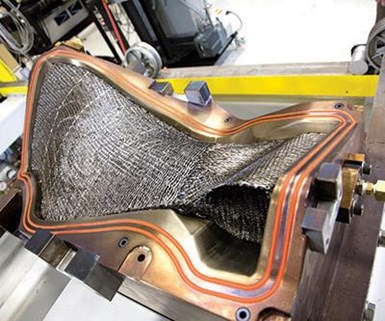

The growing sophistication of, and resulting use of, closed molding processes — high-pressure resin transfer molding, in particular — has increased demand for the fiber perform. Preforms are near-net shape reinforcement forms created by stacking and then shaping layers of chopped, unidirectional, woven, stitched and/or braided fiber into a predetermined three-dimensional form. This preform was created and shaped under heat by Albany Engineered Composites (Rochester, NH, US). The preform keeps its shape during transport to the fabricator/customer and during the fabricator's molding process because the fibers and fabrics are fixed in place by a binder resin — typically, a resin compatible with the resin that will form the composite part's matrix. Source: Albany International Corp.

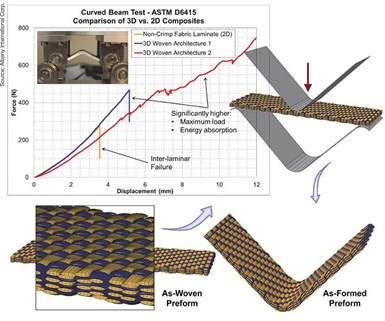

Because of the preform's potential for great processing efficiency and speed, fiber converters have developed software that can predict the behavior of fiber forms and ensure expected performance in the finished part. This diagram illustrates how one converter, Albany Engineered Composites (Rochester, NH, US) uses internally developed design tools that can perform molding process simulations as well as predict the performance of a finished 3-D composite structure. Capabilities include forming simulation and prediction of strength, stiffness and performance vs. failure criteria. Source: Albany International Corp.

Preforms are near-net shape reinforcement forms designed for use in the manufacture of particular parts by stacking and shaping layers of chopped, unidirectional, woven, stitched and/or braided fiber into a predetermined three-dimensional form. Complex part shapes can be approximated closely by careful selection and integration of any number of reinforcement layers in varying shapes and orientations. Because of their potential for great processing efficiency and speed, a number of preforming technologies have been developed, with the aid of special binders, heating and consolidation methods and the use of automated methods for spray up, orientation and compaction of chopped fibers.

Prepregs are resin-impregnated fiber forms, manufactured by impregnating fibers with a controlled amount of resin (thermoset or thermoplastic), using solvent, hot-melt or powder-impregnation technologies. Prepregs can be stored in “B-stage,” that is, a partially cured state, until they are needed for fabrication. Prepreg tape or fabric is used in hand layup, automated tape laying, fiber placement and in some filament winding operations. Unidirectional tape (all fibers parallel) is the most common prepreg form. Prepregs made with woven fibers and other flat goods offer reinforcement in two or more dimensions and are typically sold in full rolls, although small quantities are available from some suppliers. Those made by impregnating fiber preforms and braids provide three-dimensional reinforcement.

Prepregs deliver a consistent fiber/resin combination and ensure complete wetout. They also eliminate the need to weigh and mix resin and catalyst for wet layup. For most thermoset prepregs, drape and tack are “processed in” for easy handling, but they must be stored below room temperature and have out-time limitations; that is, they must be used within a certain time period after removal from storage to avoid premature cure reaction. Thermoplastic prepregs need no refrigeration and are not subject to outlife limitations, but without special formulation, they lack the tack or drape of thermoset prepregs and, therefore, are more difficult to form.

Spread tow is an individual tow (or untwisted yarn) of fiber that has been spread out until the individual filaments lie side-by-side, forming an ultra-thin ribbon. For example, a 12K tow of carbon fiber may be spread from 5 mm to 25 mm in width, reducing its thickness by 80%. These spread tows can be woven into fabric, placed to form a multiaxial noncrimp fabric (NCF) or receive liquid or powder resin to form a spread-tow tape or towpreg. Use of woven spread-tow fabric in place of more convetional reinforcments can result in a 20-30% weight savings in the composite laminate. This is achieved by closing the warp and weft interstitial gaps between warp and weft so that less resin is trapped there, but also by reducing the fiber crimp, resulting in straighter fibers, which boosts strength. Thus, the final composite laminate may use fewer, thinner plies to achieve the same or better performance.

Fiber supplier Hexcel (Stamford, CT, US), claims 5-8% reductions in fabric gaps and the ability to achieve, with carbon fiber, 6K tow properties with 3K tow areal weight, 12K tow properties with 6K tow areal weight, etc. North Thin Ply Technology (NTPT, Penthalaz-Cossonay, Switzerland) claims that any fiber can be spread and claims that very low areal weights are achievable: 30 g/m2 for PAN-based carbon fiber and 14-micron diameter quartz fiber, 35 g/m2 for 9-micron diameter glass fiber, 20 g/m2 for aramid fiber and 30 g/m2 for polybenzoxazole (PBO) and other synthetic fibers. Suppliers of spread tow reinforcements include Hexcel, NTPT, Oxeon (Boras, Sweden), Sigmatex (UK) Ltd. (Runcorn, UK), Chomarat and FORMAX (Leicester, UK). Applications include bicycles, skis, hockey sticks, rackets, sailboats, racecars and the Solar Impulse aircraft.

Recycled carbon fiber (RCF) reinforcements are available in a variety of forms, including chopped fibers cut to specific lengths, chopped fibers compounded as long fiber thermoplastic (LFT) pellets, three-dimensional net-shaped preforms, and randomly oriented chopped fiber mats — either dry or combined with thermoplastics — including polypropylene (PP), polyethylene terephthalate (PET), polyamide (PA or nylon), polyphenylene sulfide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK). The chopped fiber mats also can be processed — for example, via carding — to achieve greater fiber alignment, resulting in better mechanical properties. This variety of products is available from a range of RCF suppliers worldwide, and are recycled using pyrolysis, which burns resin from waste prepreg and cured structures. Technical Fibre Products Inc. (TFP, Schenectady, NY, US and Burneside, UK) makes veils from RCF as light as 2 g/m2.

RCF products are also made in-house from dry fiber manufacturing waste. SigmaRF products reuse Sigmatex’ in-house dry manufacturing waste by combining 45-mm to 60-mm carbon fibers with a thermoplastic carrier to form slivers which are used to make noncrimp fabrics, for example, a 220 g/m2 ±45° carbon fiber/PET biaxial NCF. Other variations include RCF/Kevlar/PEI, RCF/PA and RCF/PES.

Institute of Plastics Processing (IKV) at RWTH Aachen University (ITA, RWTH Aachen University, Aachen, Germany) has taken nascent fibers not collected by rollers during carbon fiber PAN precursor spinning — a carbon fiber production waste or byproduct — and then chopped, carbonized and formed these into homogeneous mats using a continuous airlay process.

New methods are also being developed to produce continuous recycled fibers including solvolysis using alcohols or other solvents to remove resins without burning or high temperatures, pyrolysis and unwinding of filament wound pressure vessels, and use of epoxy resins that enable the matrix to be recycled as a thermoplastic, such as Recyclamine hardeners by Connora Technologies (Hayward, CA, US).

Molding compounds are yet another way to incorporate fibers into a composite. Traditionally, these have been developed by the plastics industry and feature short fibers (2-25 mm) at low weight percentages (5-50%). Putty-like Bulk Molding Compounds Inc.(BMC) is used in injection molding while sheet molding compound (SMC) is used for larger parts and higher strength requirements, typically in a compression molding process. Glass mat thermoplastic (GMT), also a compression moldable material, has continuous random-fiber reinforcement. GMT was developed in the 1960s as a step up from short fiber-reinforced nylon. It has faced increasing competition from long fiber-reinforced thermoplastic (LFRT or LFT) which is produced by cutting small-diameter pultruded continuous glass fiber rods into pellets. LFT features continuous unidirectional fiber running the full length of the pellet and offers properties between GMT and short-glass thermoplastics. In the 1990s, machinery OEMs developed inline compounding (ILC) systems that integrate the previously separate compounding and molding processes. These direct long-fiber thermoplastic (D-LFT) systems combine resin, reinforcement and additives at the press, delivering a measured shot or charge directly to injection or compression molding equipment. This eliminates inventories of pre-compounded product and enables tailored fiber length.

SMC, BMC, GMT and LFT are used in a wide range of applications where complex shapes and molded details are required, including automotive parts, appliances (washing machine tub), medical devices, consumer goods, electronics, sporting goods, brackets, enclosures, parts for transportation vehicles and electrical applications.

Glass fiber is the most common and least expensive reinforcement used in molding compounds, aramid fiber provides wear resistance, stainless steel fiber achieves both electrostatic dissipation (ESD) and electromagnetic interference (EMI) shielding, while carbon fiber provides higher modulus and lower weight as well as ESD properties. Molding compounds reinforced with natural fibers (hemp, flax, sisal and wood-derived fibers) also have been developed, including. These are gaining popularity in automotive, sporting goods and consumer products.

Advanced molding compounds are aimed at higher performance applications including aerospace and military parts. These materials use higher performance resins, such as epoxy, phenolic, vinyl ester, bismaleimide (BMI) and polyimide, and fiber loadings from 45% to 63% by weight. Fibers include carbon and E-glass, but also higher performing S2-glass. TenCate Advanced Composites makes BMCs with epoxy, cyanate ester, Nylon, PPS or PEEK resins and carbon or S2-glass fiber in lengths from 12 mm to 50 mm. HexMC is produced by Hexcel, using 50 mm long carbon fibers and epoxy resin. A variety of other carbon fiber SMC products are available from suppliers that include Continental Structural Plastics(Auburn Hills, MI, US), Quantum Composites (Bay City, MI, US) and a joint venture between Zoltek Corporation (St. Louis, MO, US) and Magna (Paris, France).

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

Aligned discontinuous fibers come of age

Discontinuous but aligned carbon fibers are proving formable and formidable in high-performance, compound-curvature applications.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More