Fiberglass Ideal For Dry Deluge System Applications

Around 1982, offshore platforms began using dry deluge systems, where the ring main is kept full of seawater but the downstream piping is dry. The dry piping is separated from the ring main by deluge valves, which automatically open and distribute water through the dry pipe to spray nozzles during a fire. This

Share

Read Next

Around 1982, offshore platforms began using dry deluge systems, where the ring main is kept full of seawater but the downstream piping is dry. The dry piping is separated from the ring main by deluge valves, which automatically open and distribute water through the dry pipe to spray nozzles during a fire. This practice saves weight and minimizes corrosion-induced that the deluge piping is typically routed to avoid hazardous areas on the platform means that conductivity is not a requirement, but fire resistance is essential.

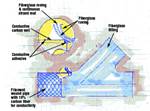

In 1991, Ameron retrofitted ballast piping and the fire protection line on BP Norway’s Valhall, a fixed-leg platform in Norway’s North Sea sector, using FRP piping to replace corroded steel. The company installed its Bondstrand pipe product, which is made with fiberglass and epoxy resin and Pitt-Char intumescent resin (supplied by PPG Industries, Springdale, Pa., USA) for the pipe’s exterior coating. The coating was reinforced with fiberglass to improve its adhesion to the pipe and add impact and scuff resistance. The pipe passed the HSE Offshore Safety Report OTI 95-634 “Jet-fire Resistance Test of Passive Fire Protection Materials,” a test standard that is accepted by oil companies.

Polysiloxane-modified phenolic resins are also a good choice for dry deluge piping. Siloxane molecules incorporated into the phenolic’s backbone chemistry improve impact resistance, pressure performance and bonded-joint adhesion without sacrificing the resin’s inherent fire resistance. To reduce wall stresses and temperature buildup during jet-fire conditions, extra plies (Ameron uses 10 to 12) of alternating polypropylene veil tape can be wrapped around fiberglass/polysiloxane-modified phenolic piping. Under extreme heat, the veil vaporizes, leaving an air gap and shear layer in the laminate, which can withstand higher heat because of the phenolic but chars when it burns. The result is alternating layers of glass, residual char from the phenolic resin and air gaps from the vaporized polypropylene — a construction that forms a virtual heat shield for the pipe structure. Ameron has supplied 9,000 ft/2,770m of fire main and dry deluge system piping of this type for the BP Marlin platform, which was activated in the Gulf of Mexico late in 2000.

Related Content

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.