Increasing the composite stack: Co-molding of dissimilar materials

This demo introduces the concept of co-molding with thermoset composites to improve the final part performance. (Sponsored)

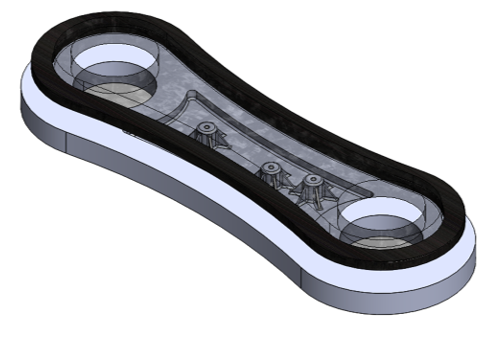

This demo introduces the concept of co-molding with thermoset composites to improve the final part performance. This overview is for those who are unfamiliar with thermoset materials and their molding processes. During this presentation, LyondellBasell will review the functional elements of composite materials and defining the types of challenges that co-molding can solve based on their size relative to the finished part. They will also discuss the use of metal inserts, including design concerns and material selection, along with more advanced concepts in the co-molding of different molding compounds and the use of additional filler bodies.

For more information on this and other LyondellBasell products, visit LyondellBasell.com and follow them online on Facebook, Twitter, and LinkedIn.

Related Content

-

Digital Demo: Secure Vacuum Bag Seal Eliminates Single-Use Sealant Tapes in Closed Mold Process

Magnum Venus Products (MVP) has developed a reusable two-part seal for the vacuum infusion closed mold process, replacing single-use sealant tapes. (Sponsored)

-

Digital Demo: UV-Cured Powder Coating on Carbon Fiber

Keyland Polymer's R&D chemist will demonstrate the UV powder coating application process followed by UV curing on a carbon fiber water bottle holder. (Sponsored)

-

Digital Demo: The Advantages of Thermoplastics Technology

From stronger, longer-lasting parts to creating sustainable options for composite parts, this demo will pique your interest in this emerging technology. (Sponsored)