Mae West: Pipe dream in Munich

Unique fiber architecture and mandrel-less filament winding process make “impossible” rotational paraboloid sculpture possible in carbon composites.

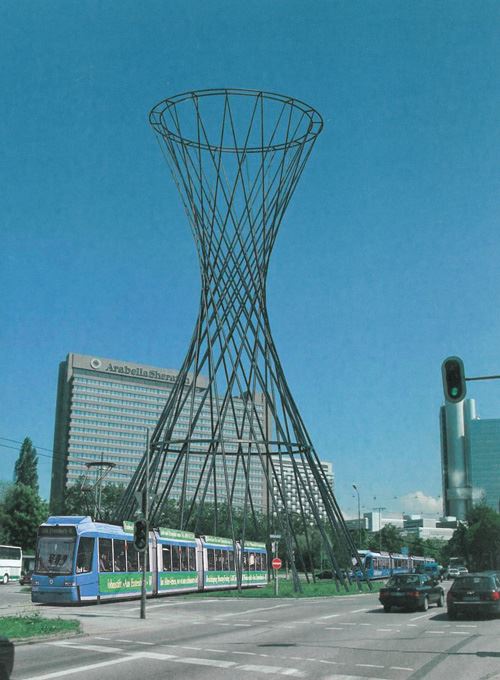

A new civic sculpture in Munich, Germany’s Effnerplatz bears at least two distinctions. The first is immediately obvious from its name: Mae West. The 52m/170.6-ft-high structure suggests the hour-glass figure of its late namesake, the voluptuous and free-spirited American movie siren of the 1930s. Another distinction is its status as a work of art dependent on the aesthetics and durability of carbon fiber-reinforced polymer. Part of a new tunnel construction for the Mittlerer Ring München urban highway, the sculpture’s principal geometric form combines a circle and a rotating movement, which relates to the round shapes of the Effnerplatz and the movement of traffic on the Mittlerer Ring road that encircles the inner city district. The sculpture’s form, a rotational paraboloid, comprises two sets of pipes: One set rises from bottom right to top left, and the other from bottom left to top right. Were it not for composites, the sculpture might not have been realized.

Art conceived in carbon

The sculpture’s genesis was an international artists’ competition, sponsored in 2002 by Munich’s Department of Public Construction and The Arts Commission. The effort was initiated as a result of the city’s so-called “2-percent clause,” which calls for two percent of all building projects to be art.

Artists from Germany, Austria and the United States, a total of eight, were invited to submit proposals for the Effnerplatz site. These were judged by a jury of art professionals. The winning artist was Rita McBride — formerly from New York and now a professor of sculpture at the Düsseldorf (Germany) Academy of Arts.

Notably, McBride envisioned the sculpture in carbon composites from the beginning. She explains that her interest in carbon fiber was piqued when she noticed that the fiber had “changed bike design quite a bit” around 2000. “I found it very beautiful,” she recalls. “It has a rare aesthetic quality that simultaneously absorbs and deflects light. The weaving possibilities are seemingly endless as well.”

McBride originally proposed telescoping carbon tubes similar to sailing masts or bicycle seat tubes for Mae West. However, the principal composites engineering and production company on the project, Carbon Grosssbauteile GmbH (CGB, Wallerstein, Germany) suggested that it would be possible to use one-piece 40m/131-ft-long carbon composite pipes on a base of 15m/49 ft long carbon-wrapped steel pipes. “When CGB came along,” McBride remembers, “it was then possible to make very long lengths and we no longer needed the telescoping idea.”

CGB’s proposal was the fruit of the company’s unusual manufacturing history. The company targets construction of very large filament wound structures. Currently CGB has the capacity to manufacture very long structural parts, up to 42m/137.8 ft in length and 800 mm/31.5 inches in diameter, and parts with significant length and very large diameters, up to 16m/52.5 ft long, 4m/13 ft in diameter. To construct such massive structures, CGB focused on improving the logistics of fiber positioning. In other words, CGB engineers sought how best to get fibrous reinforcements into the correct position, or angle, to withstand or support structural loads. As a result, CGB CEO Bernd Schottdorf is confident that “what we can build with composites would never be possible in steel.”

According to Schottdorf, CGB acted as the Mae West project and construction manager, not only designing the fiber architecture for the specific load cases, but financing all material testing for the structure as well.

Material advantages

Beyond aesthetics, probably the most important advantage composites have over traditional materials for the Mae West project is mass reduction. In steel, one 40m/131-ft-long pipe would weigh about 3 metric tonnes (6,614 lb), compared to only 0.5 metric tonne (1.102 lb) for a composite pipe of the same dimensions. As Schottdorf points out, “Thin steel pipes that would have the necessary stiffness in this length would be so heavy they would bend under their own weight.”

Equally important is the flexibility in form that composites provide, Schottdorf says. “We were able to custom-design the fiber and resin composite characteristics precisely for the specified load case of this sculpture.” CGB selected UTS50 24K carbon tow from Toho Tenax Europe GmbH (Wuppertal, Germany), an ultrahigh tenacity fiber that has high tensile strength (5,000 MPa/725,189 psi), high modulus of elasticity (245 GPa/35,534,246 psi) and low density (1,630 tex nominal linear density).

The fiber is embedded in an epoxy resin system, comprising Biresin CR84 translucent epoxy resin and Biresin CH120-6 amine hardener, both formulated by Sika Deutschland GmbH (Bad Urach, Germany) especially for CGB’s filament winding process. (Biresin is a trademark of Sika). Sika’s marketing development manager Andrew MacInally explicates its advantages: “Mainly, we concentrated on the processability of the resin system so that it would fulfill the particular requirements of CGB.” CGB specified a nontoxic resin that would cure at temperatures as low as 70°C/158°F (glass transition temperature ≥80°C/176°F), with minimal to no resin drain-off. Further, the resin has a 10-hour potlife and can be over-laminated after precure. (Although it is designed for filament winding, Sika maintains that the Biresin system also is suitable for hand lay-up.) The resin has received a certificate of approval from Germanischer Lloyd (GL, Hamburg, Germany), which provides integrated certification and assessment services for materials, manufacturers and manufacturing processes in a range of major markets.

Mae West structural design

The greatest challenge? “This structure is a very complicated load case, encompassing torque, bending and tensile stresses, which was not easy to calculate,” Schottdorf says. Following the project award, McBride worked with Werner Sobek Engineering GmbH (Stuttgart, Germany) on the structural design for six years. The extensive time span was due largely to the “democratic process that the ‘2-percent for art’ must endure,” McBride says. But another factor that contributed to the delay was concern about public safety, which was expressed by the City of Munich. “Nobody has ever built such a huge structure made of carbon fiber anywhere in public,” Schottdorf explains.

After CGB joined the team in 2009, Sobek continued to calculate wind, snow and other static loads that might be impose on the prospective structure. “When we had the load case, we then designed the fiber orientation for the composite pipes,” he continues.

CGB designed the pipe dimensions and winding patterns using CADWIND software from Material SA (Brussels, Belgium), along with its own proprietary computer design program. CGB engineers then calculated the finite element model (FEM) mesh, or fiber architecture, using ESAcomp 4.1 structural analysis and design software for composites materials from Componeering (Helsinki, Finland). The final design for the composite pipes comprises 20 plies of longitudinal, circumferential and low-angle helical fibers.

For proof of concept, CGB tested prototype pipes at the Technical University of Munich and at engineering and testing firm IMA GmbH (Dresden, Germany). “These are the two institutions that helped us verify our calculations in reality,” says Schottdorf, eventually enabling the team to obtain approval from Munich’s civil engineering auditors.

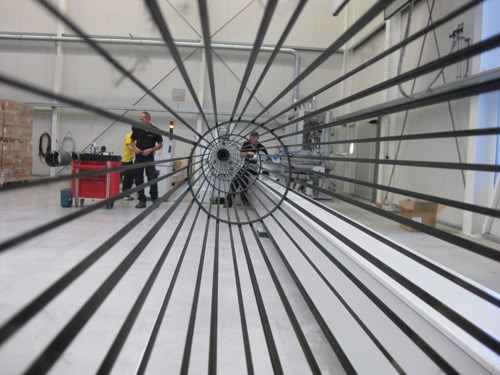

Look, Mae, no mandrel

CGB wound the composite pipes for Mae West on its patented, automated filament winding machine, which uses an innovative mandrel-less system. “You couldn’t build this structure on any other machine,” Schottdorf contends. “The big advantage of our machine is the length,” he says. “We are winding pipes in one-piece lengths up to 40m/131 ft for this sculpture.” The machine is programmed and controlled through a SINUMERIK 840D digital numerical control system from Siemens AG (Munich, Germany).

Notably, these long pipes are conical, having a slightly larger outside diameter (OD) at the bottom (275 mm/10.8 inches) compared to 225 mm/8.86 inches OD at the top. The pipe wall thickness, however, is inversely proportional: The thickness is smaller at the bottom (12 mm/0.47 inch) and the pipe is slightly thicker (18 mm/0.71 inch) at the top. Overall, the pipe thickness is “very thin with respect to the length,” observes Schottdorf.

The process begins by loading rolls of the Toho carbon tow onto creel spools mounted on a frame beside the machine. The tow is pulled through an inline resin bath fed by a fully automated supply system. Resin and hardener flow through separate pipelines from nearby barrels and are automatically mixed at the machine. Schottdorf claims that the resin is “applied so precisely” that there is no excess and, therefore, no resin-drip.

Before winding commences, a fiberglass shaft 0.75m/2.46 ft long is mounted on the headstock and tailstock of the machine. The shaft separates the carbon from a steel insert that is later bonded into the top and bottom ends of the long pipes.

Winding true zero-degree orientation

CGB’s unique winding system pulls the resin-impregnated tow around a series of evenly spaced pins at each end of the machine. The pins extend at right angles from flanges on both the headstock and tailstock of the machine (see Step 3 and 4 on p. 48). While the headstock and tailstock rotate at a pre-programmed rate of speed, the winding head pulls the wet fiber back and forth around the pins in true 0° orientation, until a pipe shape is formed that has been built from all-longitudinal fibers. This longitudinal pipe shape then provides the base — virtually an in-situ composite mandrel — on which complex helical and circumferential fibers are then wound to meet the specified load case, or fiber architecture, for that specific pipe. Winding is accomplished at a rate that can range from 120 kg/264.5 lb to as much as 200 kg/441 lb of composite per hour.

When the fiber architecture is partially complete, a heated oven is lowered over the machine, enclosing the pipe for a six- to eight-hour precure at 40°C to 50°C (104°F to 122°F). The end stocks continue to turn the pipe during the cure cycle.

When the precure cycle is complete, the oven is pulled away and the partially cured pipe becomes the mandrel over which the remaining fiber architecture and ply schedule are wound. When winding is complete, the oven is again lowered over the machine for a final cure cycle, typically eight hours, using a temperature curve that peaks at 75°C to 80°C (167°F to 176°F).

Schottdorf describes CGB’s oven, which employs a novel “green” heating scheme: “We are following an environmentally friendly approach in cooperation with the farmers in the area who are building up natural biogas heat supply systems,” he explains, pointing out that “we bring one of these natural gas pipes through our facility and use it to heat water, and then use the hot water to heat the oven for the curing process.”

After cure is complete and the cycle has ramped down to cool the pipe, the oven is pulled away. The finished pipe is then cut away from the machine at both ends by a special angle grinder that is capable of making very precise circumferential cuts.

Satisfying public safety concerns

Although highway car traffic is directed through a tunnel below the plaza, local auto traffic circles the sculpture and the local tramway passes through the sculpture’s lower structure. To satisfy the city’s concerns about public safety, therefore, CGB inserted steel tubes 0.75m/2.46 ft long — coated for corrosion-resistance — into the fiberglass shafts previously wound into both ends of the pipe. The fiberglass keeps the carbon and steel separated, preventing corrosion caused by galvanic interaction. Schottdorf says the plaza-level steel is unnecessary for mechanical reasons, but ensures crashworthiness and protects the sculpture from fire and vandalism. “We use the composite for aesthetics, here,” he says.

Using a technique licensed from IMA, the steel insert is rotated while ScotchWeld epoxy-based glue from 3M (St. Paul, Minn.) is injected through a small hole previously drilled through the carbon/fiberglass composite. “This patented technology spreads the glue in a thin sheet, coating the steel insert 100 percent,” Schottdorf says. The pipe is heated to cure the glue; the steel expands and the carbon composite contracts under heat, applying pressure around the shaft to further fix the bond. As a precautionary backup, the steel inserts also are bolted into position using hollow metal bolts. All steel inserts are fitted with a flange system for ease of connection during construction. Further, pipes destined for the lower 15m/49 ft of the sculpture are of a different construction. These are steel pipes that have been overwound with same carbon composite materials on the same winder.

Before shipment to the Effnerplatz, all pipes were topcoated with transparent Feycolor Relonit from Feycolor GmbH (Wierner Neudorf, Germany), which protects the carbon laminate from exposure to the sun’s ultraviolet radiation.

Construction of the sculpture

The sculpture installation was completed as HPC went to press. Its lower composite-overwound steel pipes had been embedded in a concrete ring at the base of the sculpture, which has a 32m/105-ft OD at this foundation. They were attached at their top to a steel ring (17m/56-ft OD) positioned 15.5m/50.8 ft above the foundation. The bottoms of the long all-composite pipes are also connected to this steel ring. The long pipes angle above that ring to connect with another steel ring, 19.5m/64 ft OD, positioned 52m/170.6 ft high, at the top of the sculpture.

Workers secured and stabilized the pipes with pipe couplings at various positions, where they intersect. Pipes on the outer section are a bit longer and pipes on the inner section are shorter, resulting in an OD of 32m/105 ft at the bottom of the sculpture and 19.5m/64 ft at the top; and the middle (Mae West’s waistline) is 8m/26 ft OD.

Other markets and future potential

Schottdorf is convinced that the CGB filament winding system could build pipes as long as 100m/328 ft for sail masts, industrial pipelines (water, oil and gas) and other applications in which long one-piece shapes are advantageous. The pipe shape, he contends, is not a constraint: “They could be elliptical or square or a combination of those,” he maintains, and they can vary in diameter, “as in the case of the Mae West sculpture.” The only real constraint in such long lengths, he quips, is “how do you get them to the site?”

“We are also trying to combine different technologies in ways they have not been combined before,” adds Schottdorf. He cites, for example, CGB’s Quickpreg system, which combines filament winding and milling technologies. In this process, CGB wet-winds a specified fiber architecture on its automated winder. The finished material is cut off the winding machine prior to cure. The result is a strong but flexible carbon composite mat, which is then frozen like a prepreg. When the time comes to finish the part, the mat is thawed, cured and then can be layed up on a mold or milled form. “We can apply this technology to very large forms,” he says.

CGB intends to continue looking for ways to make its process more economical and competitive in markets that can benefit from one-piece, long-length structural profiles.

Related Content

Sustainable Infrastructure Systems creates fiber-reinforced post-consumer plastic structural panels

Australian composites manufacturer offers a scalable building solution, already established in a pedestrian bridge application, to tackle unprocessed soft plastics waste.

Read MoreGatorbar, NEG, ExxonMobil join forces for composite rebar

ExxonMobil’s Materia Proxima polyolefin thermoset resin systems and glass fiber from NEG-US is used to produce GatorBar, an industry-leading, glass fiber-reinforced composite rebar (GFRP).

Read MoreComposites-reinforced concrete for sustainable data center construction

Metromont’s C-GRID-reinforced insulated precast concrete’s high strength, durability, light weight and ease of installation improve data center performance, construction time and sustainability.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreRead Next

Composites help create "ghostly" sculpture of bygone time

Sculptor Lawrence Argent of Argent Studios Ltd. (Denver, Colo. ) recently completed another of his several Denver-area public art installations, an internally illuminated, translucent composite sculpture called Ghost Trolley.

Read MoreComposite Sculpture Bears A Second Look

"Paperless" design and plug-free moldmaking enable cost-effective scale-up of miniature model to massive monument.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)