Predicting and mitigating failure in composite parts

Understanding the complexity of composites manufacturing resides in studying the design challenges inherent to fabrication, as much as the physics aspect. To serve this effort, CW introduces a new column, “Predicting Failure.”

Photo Credit: Getty Images

In a social setting — say, a family holiday dinner or a cocktail party or in idle conversation with a stranger — one of the questions we like to ask each other is, “So, what do you do?” The answer is almost always interesting and can lead to further discussion. If you work in the composites industry, however, answering that question can be a challenge, particularly if your interlocutor is a non-technical person. Simply referencing composites manufacturing is almost always meaningless to the listener. Carbon or glass fiber might have some meaning, but only in an abstract way. I will sometimes reference applications like concrete or wind turbines — everyone has seen those — and then explain that fiber-reinforced composites are analogous to rebar-reinforced concrete and that the blades on wind turbines are made with fiber-reinforced composite materials. And that’s usually about as far as it goes.

A few months ago, I ran across a definition of composites manufacturing that, for those of us who are technically or scientifically inclined, makes good sense. The definition actually came from a column CW published late last year, written by Navid Zobeiry, an assistant professor of Materials Science & Engineering at the University of Washington (Seattle, Wash., U.S.).

His definition was this: Processing fiber-reinforced polymer (FRP) composites is a complex and multi-physics problem of heat and mass transfer, thermo-chemical phase transitions and highly nonlinear and time-dependent viscoelastic stress developments.

The ability to predict failure of a design before that failure occurs is the optimum path to design optimization.

Perfect. Or, at least, it perfectly captures the complexity that is composites manufacturing. This single sentence nicely summarizes the hurdles that can make composites manufacturing so daunting: “multi-physics problem,” “heat and mass transfer,” “thermo-chemical phase transitions,” “viscoelastic stress developments.”

Of course, the physics of composites fabrication is not just a manufacturing challenge. It’s a design challenge as well. All of the CAD tools composites designers use must account for these variables and enable intelligent deployment of tools to help optimize and maximize fiber orientation to meet the mechanical loads of the application. The designer then relies on physical testing of the finished part to provide an ultimate assessment of the design’s performance. And, in a worst-case scenario, in-service failure can also inform the validity of a design.

In any case, any designer would likely agree that the ability to predict failure of a design before that failure occurs — whether in test or in service — is the optimum path to design optimization. It was with this idea in mind that a few months ago we here at CW wondered if we couldn’t develop a series of columns through which to explore best practices and strategies for designers to use to predict and then mitigate failure in composite parts and structures.

We engaged Hexagon Manufacturing Intelligence (Cobham, U.K.) to help us develop a new series of columns called “Predicting Failure.” As the name implies, the goal is to explore the design flaws that lead to structural failure and identify solutions to avoid such failure. Hexagon’s design experts will help us in this effort.

The first Predicting Failure can be found in the March issue, on p. 6, and is titled, “How to validate 3D-printed composite part performance.” It chronicles the design optimization of a 3D-printed bracket used to lift heavy cast metal components during CNC machining. The bracket integrates chopped and continuous fiber reinforcement, optimally placed to avoid performance failure. Manufacturing was performed with a Markforged (Cambridge, Mass., U.S.) 3D printer. You can look for additional Predicting Failure columns in other issues throughout 2022, and beyond.

More importantly, the Predicting Failure column provides an opportunity for you to explore your own failure challenges. If you have a design, part or concept that exhibits a failure mode you would like to see addressed, let me know and we will consider it as a topic for a future column. You can reach me at jeff@compositesworld.com. I hope to hear from you soon.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreThermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

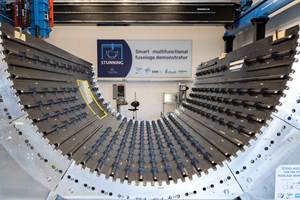

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More