Shared composite material property databases

For more than a decade, NASA, FAA, industry and academia have been working toward the goal of creating a centralized composite material property database similar to that for metals. Their efforts, while productive, have not come with the war-like strength that the standardization of metals did. The composites industry is guided by Composite Materials Handbook 17 or CMH-17 (formerly known as MIL-HDBK-17).

For more than a decade, NASA, FAA, industry and academia have been

working toward the goal of creating a centralized composite material

property database similar to that for metals. Their efforts, while

productive, have not come with the war-like strength that the

standardization of metals did.

The composites industry is guided by

Composite Materials Handbook 17 or CMH-17 (formerly known as

MIL-HDBK-17). Many regard CMH-17 as the equivalent of the metals

industry standards organization guide, MMPDS (formerly known as

MIL-HDBK-5). However, MMPDS remains the only U.S. government-recognized

public source of published design-allowable properties for commercial

and military aircraft structures and mechanically fastened joints. The

composite material allowables published in CMH-17 generally are not

accepted by the FAA or the U.S. Department of Defense (DoD) for

aircraft certification and airworthiness without additional

substantiating evidence. But CMH-17 leadership, in partnership with the

National Center for Advanced Materials Performance (NCAMP), is

committed to changing this. As witness to this, the upcoming CMH-17

revision G datasets with Complete Documentation are designed to meet

the rigors of U.S. government requirements for commercial and military

aircraft structures.

The material property shared database approach

adopted for CMH-17 revision G Complete Documentation datasets contains

many new requirements. Data submitters must now provide material and

process specifications along with the dataset. In addition, the

material supplier must produce the material under a process control

document (PCD). The specifications and PCD are designed to ensure that

material properties are stable over time and must be prepared and

maintained in accordance with FAA Advisory Circular (AC) 23-20. The new

requirements encompass the entire material property data acquisition

and qualification process, including detailed documentation of

everything from the materials to the test panel fabrication and

inspection and data analysis.

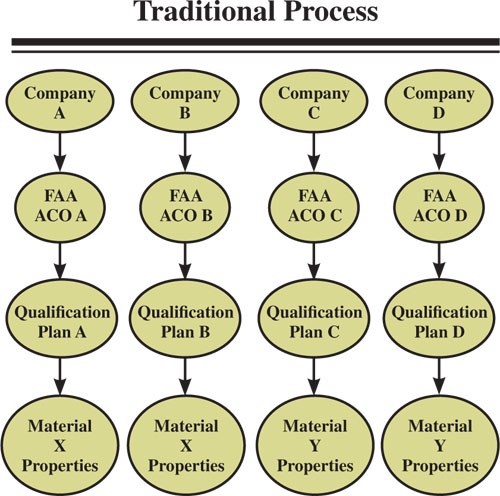

Traditionally, aircraft companies had

to generate basic lamina and laminate composite material properties for

individual composite material systems, as shown in the top diagram, at right. The same material system was often tested and qualified by

multiple aircraft companies, resulting in different proprietary sets of

allowables and separate specifications for essentially the same

material system. Efforts to share material properties were

unsuccessful, often because each company considered its data to be

proprietary.

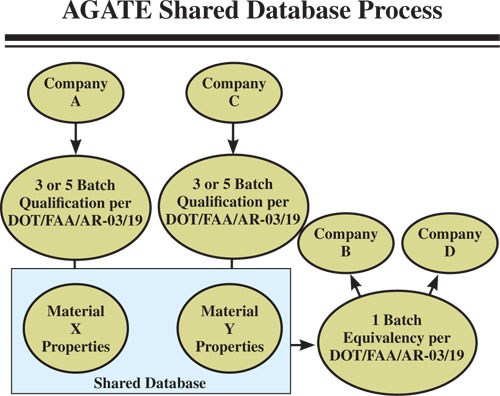

NASA AGATE Program

This began to change in 1995, when NASA started the AGATE program to revitalize the general aviation industry. The NIAR was put in charge of the AGATE Materials Working Group to develop a more efficient composite material qualification and property data acquisition process. The AGATE shared database process, as shown in the middle diagram, at right, was developed as a result of close coordination with the FAA. The process, published in DOT/FAA/AR-03/19, allows aircraft companies to share basic material properties and specifications similar to the shared database process that exists for the metals industry. After a multibatch material qualification program, the material property data, material and process specifications, and other necessary pedigree information, are included in the shared database. An equivalency process, which involves one batch of material only, is a fast and low-cost sampling process that is designed to show that a follow-on company can use the material and process specifications to reproduce the original material properties. This is necessary because the fabrication of composite parts, unlike that of aluminum parts, involves operations such as layup, bagging and curing, where process parameters could influence basic material properties.The AGATE shared database process was recognized as an

acceptable means of compliance by FAA Small Airplane Directorate Policy

Memorandum PS-ACE 100-2002-006 entitled, “Material Qualification and

Equivalency for Polymer Matrix Composite Material Systems.” After the

AGATE program ended in 2001, the FAA and NIAR continued to support the

shared database process by producing additional guidance materials,

such as recommendations for developing material and process

specifications. The FAA also continued to support efforts to add more

materials property data to the AGATE database, as evidenced by the

generation of laminate properties for Toray Composites America’s

(Tacoma, Wash.) 2510 and Park Electrochemical Corp.’s (Melville, N.Y.)

Nelcote E765. The industry also continued to support the effort. The

material user base for materials qualified using the AGATE process

continued to grow, and companies that were not originally in the AGATE

program began using the AGATE process. For example, Advanced Composites

Group Inc. (ACG, Tulsa, Okla.) generated properties for its MTM45 and

MTM45-1 prepregs.

NCAMP and beyond

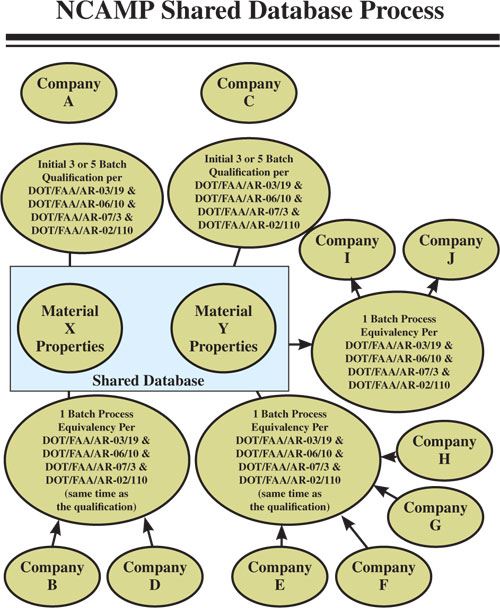

NASA scientists realized that the AGATE process should be extended beyond the general aviation segment to the entire aerospace industry. In 2005, NASA Langley established NCAMP specifically for this purpose: to refine and enhance the AGATE composite material property shared database process to a self-sustaining level in partnership with CMH-17 and FAA. Unlike AGATE, which was a “program” designed to end in 2001, NCAMP has been set up as a permanent national center within NIAR and operates independently of other NIAR laboratories and research initiatives.The NCAMP process,

as shown in the bottom diagram, at right, differs from the AGATE

process in two ways: First, NCAMP uses additional guidance materials

published by the FAA, namely DOT/FAA/AR-06/10, DOT/FAA/AR-07/3, and DOT/FAA/AR-02/110.

Second, many aircraft companies are involved; one aircraft company

fabricates the qualification test panels while other companies

fabricate the equivalency test panels. The goal of conducting

qualification and equivalency programs is to generate material

properties and basis values that can be used by all aerospace

companies. If deemed equivalent, the properties from the qualification

and equivalency programs are then pooled to create a larger dataset,

therefore providing aerospace companies with a better model of

distribution. Such pooling is possible only if the equivalency programs

are conducted at the same time as the qualification programs. NCAMP

uses the latest CMH-17 guidelines and statistical analysis tools, such as ASAP (the AGATE Statistical Analysis Program) and STAT17 (the traditional MIL-HDBK-17 statistical analysis program), to generate basis values.

As

they bear the cost of generating basic material properties, material

suppliers are freeing their customers from having to repeatedly

regenerate the basic properties. Customers can focus more on process

modeling and the testing and analysis of higher-level building blocks,

such as joints and detail element properties, which, in most cases, are

more relevant to safety and structural efficiency. There will be fewer

material specifications covering the same materials, so there will be

less material waste at material supplier, part fabricator and

maintenance facilities. Material availability will increase because

many customers will buy to the same specifications.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Shared material databases: The next chapter

John Tomblin, Ph.D., is the executive director of the National Institute for Aviation Research (NIAR) at Wichita State University in Kansas. For 10 years, he has worked in the area of general aviation material qualification and, primarily as chairman of NASA's Advanced General Aviation Transport Experiments (AGATE)

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)