Structural health monitoring: Angling for the air

Structural health monitoring (SHM) systems for composite aerostructures have been slow to deliver on their promise, but a system developed by Luna Technologies (Roanoke, Va.) is on a glide path to implementation on in-service aircraft

In development for more than a decade, structural health monitoring (SHM) systems for composite aerostructures have been slow to deliver on their promise — they’re perpetual next-generation technologies. The premise of SHM is conceptually simple: integrate a series of sensors into composite laminates and other aerostructures to detect damage that might lead to failure of the structure and then alert (electronically, in real time) an onboard or ground-based crew to the type and location of the damage. In the aerospace world, however, no technology, no matter how straightforward, is speedily adopted. Every resin, fiber, adhesive, manufacturing process and SHM system, if it is destined to fly, must endure a rigorous testing and qualification process that makes speedy implementation impossible

Into that kind of heavy head wind Luna Technologies (Roanoke, Va.) is attempting to fly its SHM technology to market. Nonetheless, the company says it’s making substantial headway and expects, eventually to, implement it on a flying aircraft.

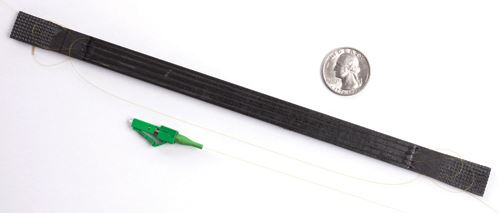

Working from technology developed at NASA Langley (Langley, Va.), Luna manufactures a dynamic distributed sensing system that uses the Rayleigh scatter of unaltered optical fiber as the sensor. With measurement rates of up to 100 Hz, cost-effective fiber sensors and significantly reduced installation time compared to equivalent foil strain gauges, this technology is designed to obtain dynamic strain data over a continuous object.

Rayleigh scatter is the light reflected from minute imperfections in an optical fiber. The scatter amplitude as a function of distance of a fiber is a unique, repeatable property of that fiber. A continuously tunable laser is used to spectrally interrogate the fiber. The reflected light from the scatter elements is then detected, demodulated and analyzed. Because the optical path difference between the reference reflector and each scatter reflection is different, the reflected signal from each scatterer is modulated by a unique frequency that is directly dependent upon the scatterer’s location in the fiber. As a fiber is subjected to environmental factors such as temperature or strain, the fiber is stretched or compressed, modifying the spacing of the scatter pattern and, thereby, its spectral response. When measured, this spectral change can be interpreted to determine the applied stimulus.

Mark Froggatt, Luna’s chief technology officer and developer of the company’s sensing technology, says optical fiber offers several advantages, including a relatively low cost (~$10/m), light weight, easy integration into composite structures and the ability to precisely measure temperature and strain at hundreds of points per meter of fiber.

Froggatt says Luna is attempting to get its technology accepted for use on flying aircraft. The starting point in this effort is implementation in design, test, verification and load frame testing, where Luna’s sensors replace foil strain gauges and the myriad wires that accompany them. Further, he notes, foil gauges typically fail at a few thousand microstrain, a value that optical fiber can easily exceed.

Dawn Gifford, Luna’s head of technology development, says the biggest advantages of the company’s fiber is easy integration with a composite structure and the ability to precisely detect and locate damage. “We’re going to sense whatever strain that fiber is experiencing at that location,” she says, adding, “We can detect the amount of strain around each defect.”

Real-world test

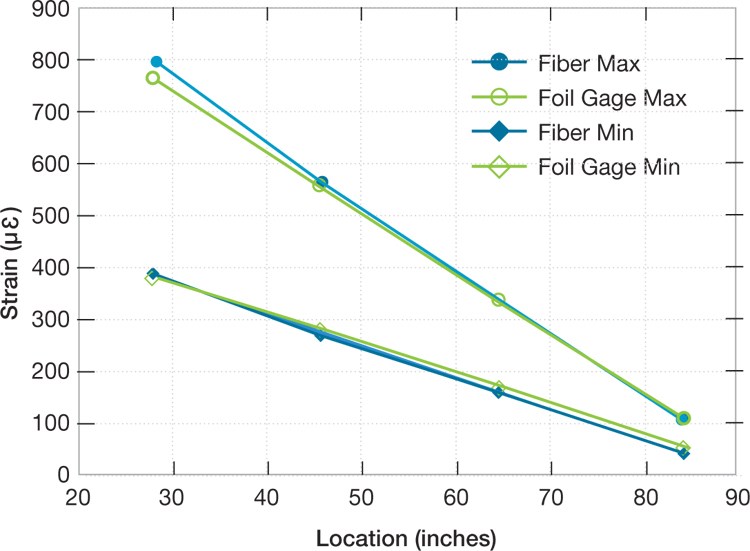

In an effort to prove that, Luna conducted a series of tests on a 9m/29.5-ft wind blade with carbon fiber spar caps, designed by Sandia National Laboratories (Albuquerque, N.M.) and manufactured at TPI Composites (Warren, R.I.). The blade featured intentional defects cast from resin prior to layup and introduced into the spar cap region of both the high-pressure and low-pressure sides of the blade at three span-wise locations. The wave height of all three defects was 3 mm/0.12 inch. Optical fibers were embedded in four layers of the composite structure. In all layers the fiber was routed in a straight line passing through points 2.54 cm/1.0 inch inboard of either end of the three defects. At approximately 1m/3.3-ft intervals, the fiber was woven into the composite material to maintain its position relative to the structure during the manufacturing process.

Following manufacture in Rhode Island, the blade was shipped to the National Wind Technology Center (NWTC, Boulder, Colo.) for additional instrumentation and pull, fatigue and property testing. In addition to the embedded fibers, optical fibers were bonded to the blade’s surface in areas of high and low pressure along its length. The fibers were offset from the spar cap centerline to coincide as closely as possible with foil gauges located on the centerline. Froggatt says the sensors not only pinpointed developing damage but also accurately predicted which load location would fail first.

“We want to succeed in the labs first, and then move out with the aircraft and into the air,” say Froggatt, noting that Luna also has placed its sensing technology in several military and commercial aircraft testing programs. Here, he notes, aircraft designers typically know what parts of the composite aerostructure are most susceptible to potentially damaging forces and, therefore, will place optical fiber selectively to monitor these regions more closely. In the air,

Luna’s system could be employed in either of two ways, says Froggatt. One way is to aggregate strain data from sensors via the company’s software and route it directly to the cockpit for flight-crew oversight. The other way is to aggregate and store data that could be accessed and assessed by maintenance crews on the ground between flights.

When could we see functional SHM systems on a flying aircraft? Froggatt and Gifford can’t say, but they see their recent progress and test results as promising: “Over the last few years, it has matured to become a very compelling technology,” says Froggatt.

Related Content

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreForvia brand Faurecia exhibits XL CGH2 tank, cryogenic LH2 storage solution for heavy-duty trucks

Part of its full hydrogen solutions portfolio at IAA Transportation 2022, Faurecia also highlighted sustainable thermoplastic tanks and smart tanks for better safety via structural integrity monitoring.

Read MoreMoving toward next-generation wind blade recycling

Suppliers, fabricators and OEMs across the composite wind blade supply chain ramp up existing technologies, develop better reclamation methods and design more recyclable wind blades.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)