The making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

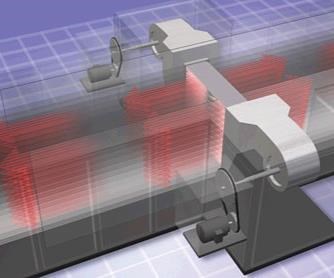

End of the line: Fibers in this carefully controlled maze of fibers (left) exit Grafil’s (Sacramento, Calif., U.S.) surface finishing stations onto winders (right) before shipment, their path determined by specific modulus. SOURCE | Grafil Inc.

Although many readers of CW use carbon fiber, few know much about how it is made. That should surprise no one. Carbon fiber producers are tight-lipped about how their product is manufactured. Each producer’s fiber differs from those of its competitors, and the processing details that give each brand its signature characteristics are considered to be intellectual property. The carbon fiber manufacturing process also is notoriously difficult and expensive. Tool-up of a single world-class production line is capital intensive — $25 million minimum for equipment alone — and can take up to two years to implement. In fact, the cost can be much more.

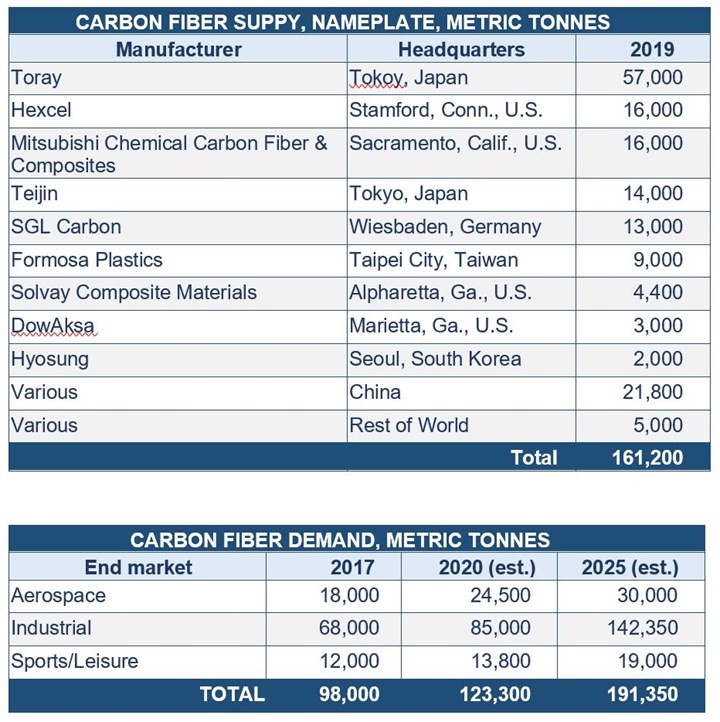

SOURCE | Carbon Fiber 2020 (Knoxville, Tenn., U.S.) preconference seminar by Tony Roberts, AJR Consultancy.

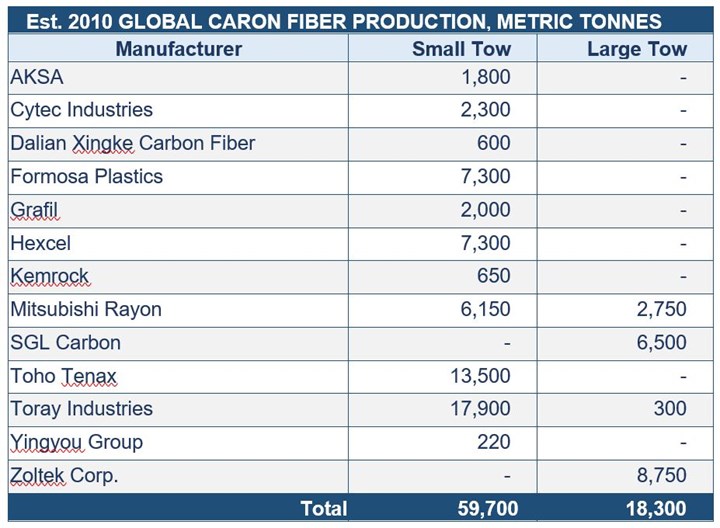

Estimated annual global carbon fiber production capacity in 2010.

Tokyo-based Mitsubishi Rayon Co. Ltd.’s (MRC) 9.4 million-ft²/874,000-m² Otake production facility, for example, is slated for a $100 million, three-year expansion — a production line that could annually produce as much as 20 million lb/9,072 metric tonnes of carbon fiber. This goes a long way toward explaining why, historically, it has been difficult to avoid the imbalances between supply and demand that cause prices to plummet and peak. Little wonder, then, that the current cadre of carbon fiber producers numbers less than a dozen worldwide.

HPC, with the help of several carbon fiber process suppliers, recently peeked behind the veil of secrecy to find this more inclusive, if still incomplete, picture of the process.

A definitive difference

Unlike metals, which are homogeneous and, by design, have properties that conform to established standards, making each producer’s P20 steel, for example, interchangeable with another’s, composites are heterogeneous. Composed of combinations of unlike materials (fiber and resin), their variability, and therefore, tailorability, are central to their appeal. Accordingly, carbon fiber producers make products that are similar but not identical. Carbon fiber varies in tensile modulus (or stiffness determined as deformation under strain) and tensile, compressive and fatigue strength. PAN-based carbon fiber is available today in low modulus (less than 32 million lbf/in² or <32 Msi), standard modulus (33 to 36 Msi), intermediate modulus (40 to 50 Msi), high modulus (50 to 70 Msi) and ultrahigh modulus (70 to 140 Msi). Fiber, which is available in bundles called tow, comes in many sizes, ranging from 1K to 350K (1K equals 1,000 filaments that range from 5 to 10 microns in diameter). Products also vary in the degree of carbon content and type of surface treatment/coating.

“The complexity inherent in carbon fiber composites is the very thing that adds value to structures made from carbon fiber,” says Steven Carmichael, director of sales and marketing for MRC subsidiary Grafil Inc. (Sacramento, Calif). “Like making fine wine, the right amount of patience, finesse and processing expertise brings out the subtleties in carbon fiber that add value.” That value, of course, is very high: As a metal replacement, carbon fiber composites offer 10 times the strength of steel at half the weight.

In simplest terms, carbon fiber is produced by pyrolysis of an organic precursor fiber in an inert atmosphere at temperatures above 982°C/1800°F. Carbon fiber manufacture, however, is a complex undertaking. Grafil’s 60,000 ft²/5,574m² plant in Sacramento, Calif. — small in comparison to MRC’s Otake plant, even after its 2 million-lb/544-tonne capacity expansion in 2005, with side-by-side production lines — provided the basis for HPC’s walk-through of the primary production phases. These are polymerization and spinning, oxidation (also referred to as stabilization), carbonization (sometimes inaccurately referred to as graphitization), surface treatment and sizing application. Throughout the process, tight tolerances define the fiber’s ultimate utility. “A target coefficient of variation on yield is 1%,” says Gordon Shearer, Grafil’s operations director, noting that real-world variation runs about 3% for the small tow (1K to 24K) that is used in demanding applications, such as aircraft (hence, its designation as aerospace grade), while large tow (industrial or commercial grade) can vary up to 15%.

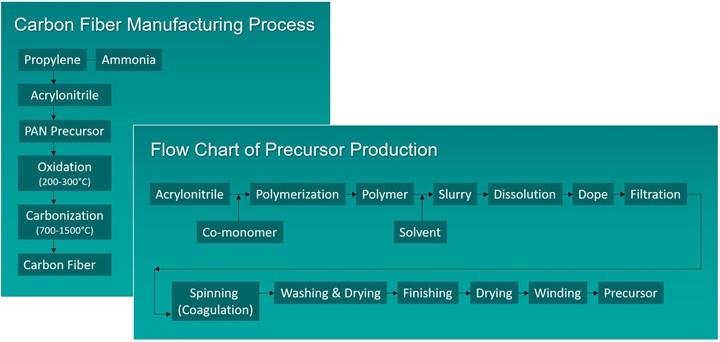

The primary steps in the two-stage process used to manufacture PAN-based carbon fiber include steps in the process used to manufacture the polyacrylonitrile (PAN) “backbone.” SOURCE | Grafil Inc.

Polymerization

The process begins with a polymeric feedstock known as a precursor (“that which comes before”), which provides the fiber’s molecular backbone. Today about 10% of produced carbon fiber is made from a rayon- or pitch-based precursor, but the majority is derived from polyacrylonitrile (PAN), made from acrylonitrile, which is derived from the commodity chemicals propylene and ammonia.

For that reason, this article depicts production of PAN-based carbon fiber.

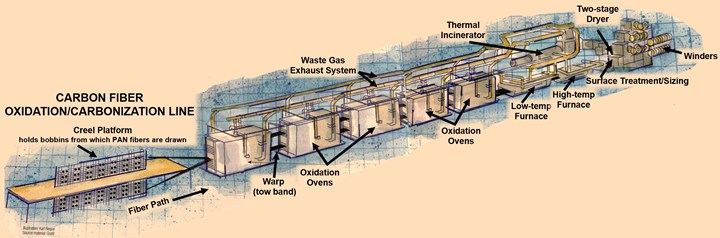

A simplified representation of a carbonization line.

Illustration | Karl Reque; Source material | Grafil Inc.

Converting PAN into carbon fiber has challenged producers for more than 30 years. Carmichael adds that most of a carbon fiber producer’s investment is spent on precursor, and the quality of the finished fiber is directly dependent on that of the precursor. Specifically, Shearer notes, attention to precursor quality minimizes variation in the yield, or length per unit of fiber weight.

Generally, precursor formulation begins with an acrylonitrile monomer, which is combined in a reactor with plasticized acrylic co-monomers and a catalyst, such as itaconic acid, sulfur dioxide acid, sulfuric acid or methylacrylic acid. Continuous stirring blends the ingredients, ensures consistency and purity and initiates the formation of free radicals within the acrylonitrile’s molecular structure. This change leads to polymerization, the chemical process that creates long-chain polymers that can be formed into acrylic fibers.

The details of polymerization, such as temperature, atmosphere, specific comonomers and catalyst are proprietary. According to Peter Morgan, author of Carbon Fibers and Their Composites (CRC Press, 2005), “polymerization should achieve at least 85% acrylonitrile content and relative molecular weight of 100,000 g/mole with uniform distribution in order to imbue PAN white fiber with good mechanical properties.” MRC’s precursor as used by Grafil, for example, achieves 94 to 98% acrylonitrile content.

After washing and drying, the acrylonitrile, now in powder form, is dissolved in either organic solvents, such as dimethyl sulfoxide (DMSO), dimethyl acetamide (DMAC) or dimethyl formamide (DMF), or aqueous solvents, such as zinc chloride and rhodan salt. Organic solvents help avoid contamination by trace metal ions that could upset thermal oxidative stability during processing and retard high-temperature performance in the finished fiber. At this stage, the powder-and-solvent slurry, or precursor “dope,” is the consistency of maple syrup. The choice of solvent, and the degree to which the dope’s viscosity can be controlled (by means of extensive filtration), are critical to the success of the next phase, fiber formation.

Spinning

PAN fibers are formed by a process called wet spinning. The dope is immersed in a liquid coagulation bath and extruded through holes in a spinneret made from precious metals. The spinneret holes match the desired filament count of the PAN fiber (e.g., 12,000 holes for 12K carbon fiber). This wet-spun fiber, relatively gelatinous and fragile, is drawn by rollers through a wash to remove excess coagulant, then dried and stretched to continue the orienting of the PAN polymer. Here, the filament’s external shape and internal cross-section are determined by the degree to which the selected solvent and coagulant have penetrated the precursor fiber, the amount of applied tension and the percentage of filament elongation. The latter is proprietary to each producer, but Morgan asserts that the stretch rate can be up to 12 times the initial pliability of precursor fiber.

An alternative to wet spinning is a hybrid process called dry jet/wet spinning, which uses a vertical air gap between the fiber and coagulate bath. This creates a smooth, round PAN fiber that can enhance the fiber/matrix resin interface in composite materials.

The last step in PAN precursor fiber formation is the application of a finishing oil to prevent the tacky filaments from clumping. The white PAN fiber then is dried again and wound onto bobbins.

Oxidation

These bobbins are loaded into a creel that feeds the PAN fiber through a series of specialized ovens during the most time-consuming stage of production, oxidation. Before they enter the first oven, the PAN fibers are spread flat into a tow band or sheet referred to as warp. The oxidation oven temperature ranges from 392°F to 572°F (200°C to 300°C). The process combines oxygen molecules from the air with the PAN fibers in the warp and causes the polymer chains to start crosslinking. This increases the fiber density from ~1.18 g/cc to as high as 1.38 g/cc.

To avoid runaway exotherm (the total exothermic energy released during oxidation, estimated at 2,000 kJ/kg, poses a real fire hazard), oven manufacturers use a variety of airflow designs to help dissipate heat and control temperature (see sidebar, below). Matt Litzler, president of C.A. Litzler Co. Inc. (Cleveland, Ohio), observes that “every precursor has its own exothermic pattern. Since individual precursor chemistry is fixed, control of temperature and airflow in the oxidation oven is adapted to each precursor and provides stabilization of the exothermic reaction.”

Oxidation time varies, driven by specific precursor chemistry, but Litzler estimates that 24K tow could be oxidized at about 43 ft/13 m per minute on a large production line with multiple oxidation ovens. Randy Strop, general manager for oven manufacturer Despatch Industries (Lakeville, Minn.), says an elapsed time of 60 to 120 minutes is typical, as are four to six ovens per production line, with ovens stacked to provide two heating zones that offer 11 to 12 passes of the fiber per oven. In the end, the oxidized (stabilized) PAN fiber contains about 50 to 65% carbon molecules, with the balance a mixture of hydrogen, nitrogen and oxygen.

Carbonization

Carbonization occurs in an inert (oxygen-free) atmosphere inside a series of specially designed furnaces that progressively increase the processing temperatures. At the entrance and exit of each furnace, purge chambers prevent oxygen intrusion because every oxygen molecule that is carried through the oven removes a portion of the fiber, explains Robert Blackmon, VP of the Process Systems Div. at furnace source Harper International (Lancaster, N.Y.). This prevents loss of the carbon produced at such high temperatures. In the absence of oxygen, only noncarbon molecules, including hydrogen cyanide elements and other VOCs (generated during stabilization at concentration levels of 40 to 80 ppm) and particulate (such as local buildup of fiber debris), are removed and exhausted from the oven for post-treatment in an environmentally controlled incinerator. At Grafil, carbonization begins in a low-temperature furnace that subjects the fiber to 1292-1472°F (700-800°C) and ends in a high-temperature furnace at 2192-2732°F (1200-1500°C). Fiber tensioning must be continued throughout the production process. Ultimately, crystallization of carbon molecules can be optimized to produce a finished fiber that is more than 90 percent carbon. Although the terms carbon and graphite are often used interchangeably, the former denotes fibers carbonized at about 1315°C/2400°F and that contain 93 to 95% carbon. The latter are graphitized at 1900-2480°C (3450-4500°F) and contain more than 99 percent elemental carbon.

The number of furnaces is determined by the modulus desired in the carbon fiber; part of the relatively high cost of high- and ultrahigh-modulus carbon fiber is due to the length of dwell time and temperatures that must be achieved in the high-temperature furnace. While dwell times are proprietary and differ for each grade of carbon fiber, oxidation dwell time is measured in hours, but carbonization is an order of magnitude shorter, measured in minutes. As the fiber is carbonized, it loses weight and volume, contracts by 5 to 10% in length and shrinks in diameter. In fact, the demonstrated conversion chemistry ratio of PAN precursor to PAN carbon fiber is about 2:1, with less than 2% permutability — that is, considerably less material exits the process than goes into it.

Surface treatment and sizing

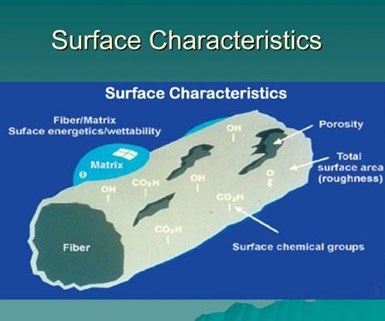

Surface treatment and sizing increase the fiber’s total surface area and porosity and alter its surface energy to improve adhesion between the fiber and the resin matrix in a composite. SOURCE | Grafil Inc.

The next step is critical to fiber performance and, apart from the precursor, it most differentiates one supplier’s product from its competitors’ product. Adhesion between matrix resin and carbon fiber is crucial in a reinforced composite; during the manufacture of carbon fiber, surface treatment is performed to enhance this adhesion. Producers use different treatments, but a common method involves pulling the fiber through an electrochemical or electrolytic bath that contains solutions, such as sodium hypochlorite or nitric acid. These materials etch or roughen the surface of each filament, which increases the surface area available for interfacial fiber/matrix bonding and adds reactive chemical groups, such as carboxylic acids.

Next, a highly proprietary coating, called sizing, is applied. At 0.5 to 5% of the weight of the carbon fiber, sizing protects the carbon fiber during handling and processing (e.g., weaving) into intermediate forms, such as dry fabric and prepreg. Sizing also holds filaments together in individual tows to reduce fuzz, improve processability and increase interfacial shear strength between the fiber and matrix resin. Carbon fiber producers increasingly use a sizing appropriate to the customer’s end use (see sidebar, below and “Advances in sizings and surface treatments for carbon fibers”). At Grafil, Carmichael adds, “we can customize surface treatment and sizing to a particular customer’s resin characteristics, as well as specific properties desired in the composite.”

According to Andy Brink, cofounder of the former Hydrosize Technologies (Raleigh, N.C.), now part of Michelman (Cincinnati, Ohio), which he serves as business development manager, “Polymeric film formers made by the dispersion of particles suspended in water provide a stable chemistry that creates a good coating when dried. The speed of most carbon fiber lines allows for fairly uniform sizing application that minimizes aggregate clumps or bare spots.”

When the sizing dries, the long process is complete. Grafil (as do other suppliers) separates individual tows out of the warp and winds them onto bobbins for shipment to customers, including prepreggers and weavers.

If an industry’s history serves as a precursor of its future, the sheer magnitude of machinery and manufacturing acumen required for the successful transformation of white PAN fiber into black carbon fiber suggests that producing this advanced material is not a business for the faint of heart or the inexperienced. Three decades of processing refinement have brought technology maturity and the ability to translate superior performance and application versatility through the fibers to advanced composites. What has gone before both technologically and economically sets the stage for the potential growth in demand that marks the future.

Related Content

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

Advances in sizings and surface treatments for carbon fibers

As carbon reinforcements find new applications, unfamiliar processes and resin systems make sizing and treatment surprisingly hot topics.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More