The Private Space Race

NASA passes the development torch to legacy contractors and NewSpace entrepreneurs, igniting a new competition in space transport.

Share

Since the Obama Administration’s cancellation of NASA’s Constellation program, the spotlight — and government space policy — has focused on the private space industry. More importantly, so have government development dollars.

“We will be providing industry with NASA technical expertise,” said NASA’s deputy administrator Lori Garver, speaking at the U.S. Federal Aviation Admin.’s Commercial Space Transportation Conference in February. “We will provide serious seed money ... and a firm commitment to buy crew transportation services on the market side.” To diversify its risk, NASA is funding competitive systems. “No single commercial system will represent the critical path,” says Garver. “We’re going to see the most exciting space race that NASA’s seen in a long time, and there’s likely to be more than one winner.”

NASA has made good on the first promise, doling out funds not only to expected players — Boeing, Lockheed Martin, United Launch Alliance — but several “NewSpace” companies, the term now used of firms run by entrepreneurs willing to risk their own money to develop private avenues into space.

Affordable, reusable launch system

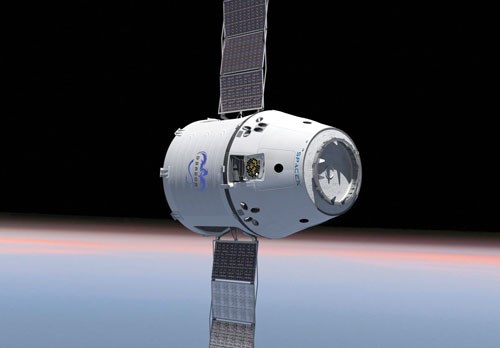

SpaceX (Space Exploration Technologies Corp., Hawthorne, Calif.) recently leaped into contention with the successful June 7 launch (top photo, at right) of its 180-ft/55m tall two-stage Falcon 9 rocket. Although SpaceX founder/CEO Elon Musk declared the event “a major milestone not only for SpaceX but the increasingly bright future of space flight,” other milestones await. The Falcon 9 and its Dragon orbital craft (see second photo, at right) must first demonstrate their capabilities under a $278 million Commercial Orbital Transportation Services (COTS) agreement before SpaceX can use them to supply the International Space Station (ISS) under a $1.6 billion Commercial Resupply Services (CRS) contract for a minimum of 12 cargo flights. But since the launch, SpaceX signed what is reportedly the largest-ever commercial and, more importantly, non-NASA launch deal for $492 million with Iridium Communications Inc. (McLean, Va.) to replace the latter’s existing satellites between 2015 and 2017.

Intended to be fully recoverable, the Falcon 9 is capable of inserting an 11-ton payload into low Earth orbit (LEO). Although the first and second stage barrels and domes are aluminum, a carbon composite interstage structure joins the stages and houses the second stage’s engines and four parachutes that return the first stage to Earth. The interstage is 3.6m/12-ft in diameter and ~8m/~26-ft tall.

A switch from an aluminum to a composite interstage was made during development of the company’s Falcon 1 rocket, which began in 2002. “Falcon 1 was essentially a materials proving ground for the Falcon 9,” says Chris Thompson, VP, Structures and Development Operations at SpaceX, noting that “the composite interstage reduces mass by between 1,000 lb and 1,500 lb.”

Toray Industries Inc. (Tokyo, Japan) T-700 multidirectional carbon fiber material is used for the facesheets, with vented aluminum honeycomb for the core. “Ply orientations are dependent upon load paths, positioning of cutouts, and requirements of additional loading, such as in and around the safe-separation fittings,” explains Thompson.

SpaceX installed laser projection systems from Laser Projection Technologies (LPT, Londonderry, N.H.) and Assembly Guidance Systems Inc. (Chelmsford, Mass.), and the company uses FiberSIM software from VISTAGY (Waltham, Mass.) to produce the fiber layup drawings. “The projection systems have cut layup time by nearly half,” says Thompson.

The interstage is oven-cured in-house over the course of one day, according to Thompson, and includes a rigorous ramp-up procedure. “With the number of plies that we’re dealing with, our decision not to use an autoclave initially led to some challenges in terms of learning how to get necessary compaction to avoid large surface area voids between the core material and the facesheets,” explains Thompson. “We were able to work through these challenges during coupon testing.”

The rocket’s nine SpaceX-built Merlin jet fuel/liquid oxygen (LOX) engines generate nearly 1 million lb of thrust. They’re integrated into a truss structure that distributes the thrust upwards into the first stage tank. Above the truss, a carbon composite skirt houses the plumbing that feeds LOX and fuel to the engines.

There are no immediate plans to convert first- or second-stage tanks to composites, says Thompson. “Because we’re dealing with a cryogenic tank in the first stage, it becomes more complicated to move to composites,” he explains, adding that “it takes us less than three weeks to build the first-stage tank in aluminum. Without a multimillion dollar tape laying machine and other automated equipment, it would be nearly impossible to do this in composites efficiently and economically.”

Thompson does, however, see a “tremendous amount of opportunity for composites in the right applications.” The company has installed a thermoforming press to more quickly produce smaller composite components that were produced previously by hand layup. “Also, we have a 5.2m/17-ft fairing program kicking off later this year that will use composites,” he adds.

Initially designed for composites, the Dragon’s pressure vessel was built with aluminum to ensure success under the company’s delivery deadlines. However, its thermal protection system’s carrier structures and its primary heat shield are made from bismaleimide (BMI) prepregs. The former are fabricated with materials from Advanced Composites Group Inc. (ACG, Tulsa, Okla.) and Cytec Industries (Woodland Park, N.J.). The latter is a BMI sandwich structure with a Rohacell foam core from Evonik Foams Inc. - ROHACELL (South Magnolia, Ark.).

When the Dragon reenters Earth’s atmosphere at around 15,660 mph (25,200 kmh), heating the shield’s exterior to 1850°C/3362°F, the capsule’s interior will be kept at room temperature by a few inches of PICA-X heat-shield ablator, a rigid, lightweight epoxy-impregnated carbon foam developed by SpaceX’s propulsion group with the assistance of NASA, the originator of the phenolic-impregnated carbon ablator (PICA). The material also is used as a heat shield on the Falcon 9 second stage, on its return from orbit for recovery and reuse.

“We tested three different variants,” said Tom Mueller, VP of propulsion at SpaceX. “Compared to the PICA heat shield flown successfully on NASA’s Stardust sample return capsule, our SpaceX versions equaled or improved the performance of the heritage material.”

SpaceX has more than 40 flights on manifest, including three demonstration flights by spring 2011 for NASA’s COTS program. And, as a free-flying spacecraft, Dragon also provides a platform for in-space technology demonstrations and scientific instrument testing. SpaceX is currently pursuing commercial, non-ISS Dragon flights under the name “DragonLab.” Further, Falcon 9 and Dragon reportedly meet NASA’s standards for astronaut transport, allowing for a comparatively rapid transition from cargo to crew capability within three years of receiving a crew transport contract.

Building on small orbital successes

Orbital Sciences Corp. (Dulles, Va.) also has been tapped to resupply the ISS. Its $1.9 billion CRS contract calls for eight flights from 2011 to 2015, and Orbital is leveraging its experience to build an unmanned Cygnus space freighter and a new rocket, the Taurus II, to launch it.

Founded in 1982, Orbital has a proven track record with small-to-medium rocket launches for commercial customers, the U.S. military and NASA. Orbital’s small Pegasus XL and Taurus XL rockets have drawn 30 NASA scientific and technology-demonstration mission assignments since 1990. NASA has selected the company to launch the Carbon Observatory-2 (OCO-2) satellite on a Taurus XL in 2013, despite a failed attempt in 2009.

The new two-stage, medium-class Taurus II builds on its smaller predecessors and is capable of delivering single or multiple payloads weighing up to 7,000 lb/3,175 kg. Prime contractor Orbital’s experienced Taurus II team includes Applied Aerospace Structures Corp. (AASC, Stockton, Calif.), which is responsible for composite primary structures. These include a 3.9m/12.7-ft diameter by 9.9m/32.4-ft-long payload fairing (aluminum honeycomb core between carbon/epoxy facesheets), and several shorter barrel components of 1.8m/6 ft in length or less: a fairing adapter, the stage 2 motor adapter, the stage 2 interstage, the payload adapter, and the avionics cylinder. The initial launch for the Taurus II is scheduled for 2011.

AASC also will manufacture and test the 12-sided, 2.6m/103-inch diameter by 1.27m/50-in tall Cygnus structure, which is based on Orbital’s STAR 2 platform. It will comprise forward and aft aluminum rings and carbon facesheets with aluminum honeycomb core for the forward/aft decks, bulkhead and gussets (the remaining parts will be metal-bonded aluminum facesheet panels). The composite structure will house the spacecraft’s motors and maneuvering control system.

Although the Orbital contract does not include ISS crew transport, the company believes it is well positioned to provide it, given its experience developing NASA’s Orion capsule launch abort system.

Designing an LEO crew vehicle

One crew transport is under development at Denver, Colo.-based Sierra Nevada Corp. (SNC) Space Systems. Awarded the biggest chunk of NASA Commercial Crew Development (CCDev) program funds — $20 million — SNC Space Systems was established in 2009 to join SNC subsidiary MicroSat Systems and SpaceDev and realize the latter’s Dream Chaser. Modeled after NASA’s early 1990s HL-20 lifting body concept and designed to ferry a crew of six and cargo to the ISS or other LEO destinations, Dream Chaser is a piloted solution. Fitted with SpaceDev’s hybrid rocket technology for orbital maneuvers (the same employed by Mojave, Calif.-based Scaled Composites’ SpaceShipOne when it won the Ansari X Prize in 2004), the craft launches vertically and lands horizontally on a conventional runway. SNC is working with Denver, Colo.-based United Launch Alliance to launch Dream Chaser atop an Atlas V rocket.

SNC plans to upgrade the design with composites and believes the cylindrical shape of its pressure vessel may make it more suitable for composites than a more complex capsule shape. Reportedly, AdamWorks (Centennial, Colo.) will develop internal structures for structural testing. Boeing Phantom Works (St. Louis, Mo.) will build the test article. Also, Straight Flight (Englewood, Colo.), an SNC aircraft repair subsidiary, is reportedly building the tooling and some of the exterior body panels. SNC plans to have a an orbital vehicle in service by 2014.

Providing the crew escape system

Backed by Amazon.com founder Jeff Bezos, Blue Origin (Kent, Wash.) operates a private spaceport in West Texas, where, under a shroud of secrecy, it is developing New Shepard, a vertical takeoff/vertical landing (VTVL) suborbital vehicle. The firm has received $3.7 million in NASA CCDev funds to support development of an astronaut escape system and build a composite pressure vessel prototype for ground-based structural testing.

This NewSpace firm finds itself in good company. Along with SNC, other recipients of NASA funds for crew development include the Houston, Texas-based Boeing Space Exploration Div. of The Boeing Co. ($18 million) and United Launch Alliance ($6.7 million).

The “push” escape system would employ thrusters under the crew cabin to lift it away from the launcher in the event of a malfunction, rather than using a conventional NASA “tractor” type escape system, mounted on top of the crew capsule to pull it away. A composite pressure vessel would reduce the crew capsule’s weight, and Blue Origin is reportedly working with NASA to leverage lessons learned on the composite crew module (CCM) pressure vessel developed alongside NASA’s baseline and mostly metal Orion design (see the sidebar "Building on CCM lessons learned" at the end of this article or click on same under "Editor's Picks").

Blue Origin began test flights in 2006 with its Goddard demonstration vehicle, which the company says doesn’t represent the final launch vehicle, but it has been a source of many lessons learned. What is known is that the New Shepard reusable launch vehicle (RLV) stacks the crew capsule on top of the propulsion module and will be capable of separating and operating autonomously during flight. The company is currently targeting the research and education market, as well as space tourism.

Under development is a standard cabin payload system to host experiments inside the New Shepard crew capsule. The company has identified three programs for its Phase 1 research flight demonstration project. Test flights could occur as early as 2011, with unmanned commercial operations shortly thereafter. New Shepard reportedly could house three or more astronauts, but no date has been set for manned commercial flights.

Retooling for suborbital tourism

HPC has followed closely the development of fledgling space tourism firm Virgin Galactic’s all-composite captive-carry launch system (see “New launch system ...." and "Virgin Galactic rolls out ...." under Editor's Picks"). Built by The Spaceship Co. (Mojave, Calif.), a joint venture of Scaled Composites and London, U.K.-based Virgin Group, the SpaceShipTwo suborbital craft and the WhiteKnightTwo launch aircraft (see photos, at right) are scaled-up versions of Scaled systems that claimed the Ansari X Prize.

Renamed Eve, the launch aircraft’s one-piece wing spar measures 140-ft/43m long — the longest carbon-composite aviation part ever manufactured. The first of several planned suborbital craft, the Virgin Space Ship (VSS) Enterprise, is designed to carry two pilots and six passengers. Both Eve and Enterprise were hand built, using new MTM45-1 out-of-autoclave prepregs developed by Advanced Composites Group Ltd. (ACG, Heanor, Derbyshire, U.K.). The prepreg features a variable-cure-temperature toughened epoxy matrix optimized for low-pressure vacuum bag processing in both prepreg and film infusion formats. MTM45-1 may be cured at temperatures as low as 80°C/176°F, allowing the use of low-cost tooling for prototypes and short production runs.

Eve has substantially completed its flight-test program (27 fights so far), and Enterprise, rolled out in December 2009, has completed two captive-carry flights. Full-scale test firings of its hybrid rocket motor began at SNC this summer, with a followup drop/glide tests program. The first powered test of Enterprise is expected in early 2011. Reportedly, Enterprise (and several forthcoming clones) will be capable of flying twice daily, and Eve will support four spaceflights a day. Virgin Galactic aims to fly 500 passengers in the first year of commercial operations.

Selling a ticket for one to space

Smaller in scale, the Lynx suborbital spacecraft from Mojave-based XCOR Aerospace is a small rocket-powered aircraft designed to take off from a runway and then make a steep ascent, accelerating to Mach 2 (~1,522 mph/~2,450 kmh) with 2.5 G-force within three minutes. Capable of carrying a pilot and one passenger with a payload on a suborbital path, the Lynx Mark I will reportedly fly to 61 km/200,000 ft and provide one minute of microgravity, while the Lynx Mark II will be able to reach 100 km/330,000 ft and provide nearly three minutes of microgravity.

XCOR has a contract to provide suborbital space launch services via the Lynx Mark II for the Yecheon Astro Space Center in South Korea under a “wet lease” model (XCOR will provide the spacecraft, crew, maintenance and insurance). The Lynx is currently under construction in-house. Test flights are expected to begin in the second half of 2011 and should last 9 to 18 months.

The Lynx Mark I employs a carbon/epoxy construction with a thermal protection system for its leading edge. The Lynx Mark II is made from carbon/cyanate ester with a nickel alloy for the nose and leading-edge thermal protection.

“Composites … allow us to work with seamless complex shapes, such as the cabin pressure vessel and outer mold line of the vehicle,” explains XCOR’s Mike Massee. “In the production version ... the outer skin of the composite LOX tank and inner skin of the fuselage are one in the same, saving quite a bit of weight in structural support.”

For this purpose, XCOR is developing a cryo-compatible composite material, trademarked Nonburnite. “Unlike ordinary composites, Nonburnite is not flammable in an oxygen-rich environment and resists microcracking at the very cold temperatures required for LOX storage,” says Massee.

Typically, LOX tanks are made of aluminum or stainless steel. XCOR uses a thermoplastic fluoropolymer composite material with a foam core that serves as thermal insulation as well as structure. XCOR reports that “compared to carbon/epoxy, it is noncombustible, and compared to aluminum, it has lower density, lower coefficient of thermal expansion and higher strength.”

Cutting costs via trial and error

With fully reusable VTVL suborbital research and passenger flights in its sights, Armadillo Aerospace’s (Rockwall, Texas) technology is similar to NASA’s but reportedly will be built at a price that will eventually put space travel within reach of other than the wealthy. The company’s existing MOD and Super-MOD vehicles reach lower altitudes using LOX-ethanol and LOX-methane engines, but two progressively more advanced systems — the Tube and the SOST — are under construction. The four rockets are an outgrowth of what Armadillo’s communications team sees in terms of step-by-step progress: “We approach rocket design much like software design. We build ... incremental designs that we can test constantly and work out all the kinks as we go.”

MOD was awarded first prize in Level 1 of NASA’s Lunar Lander Challenge in 2008. Super-MOD has additional outboard composite high-pressure tanks. Armadillo is currently offering payload opportunities and is reconfiguring both vehicles to a target maximum altitude of 50 km/164,042 ft. The Tube, scheduled to begin carrying commercial payloads in third-quarter 2010, employs a conventional rocket-style vehicle and is designed to travel to heights of 100 km/328,084 ft. The SOST transport consists of a four-tank arrangement with a capsule for manned and unmanned flights. Test flights are scheduled for 2011, and commercial passenger flights could begin as early as the end of 2012.

Inflatable space stations

Bigelow Aerospace (Las Vegas, Nev.) is looking beyond the ISS to next-generation space stations. The company hopes to house astronauts, scientists and even tourists in its expandable space modules, which use thick composite walls to protect inhabitants.

The first of Bigelow’s orbital stations — the mini Genesis I and II — have been orbiting 300 miles/483 km above Earth since launches in 2006 and 2007, respectively. Next up is a full-scale 180m³/6,357 ft³ module, Sundancer. Designed to house three people, long-term, and as many as six for short-term stays, Sundancer has its own power, environmental-control and life-support systems and avionics. Bigelow also has developed the BA-330 module, with nearly twice the volume of Sundancer.

Expandable space modules were first proposed and designed by NASA under the TransHab program as potential ISS crew quarters. After TransHab was canceled, Bigelow acquired the rights to commercialize several of NASA’s key module technologies.

According to one Bigelow patent, “typical materials used to form the TransHab module’s walls include Nomex, Kevlar, and a variety of other fabric or sheet materials. Sponge-like materials, such as open cell elastomers, are layered between these sheets. These elastomer layers are compressed prior to launch. Once in orbit, the elastomeric layers are allowed to expand, the module is pressurized, and the space module expands into its deployed configuration. The elastomer layers act to form the wall of the module and also provide insulation.”

Bigelow modified the TransHab design, adding windows and selecting Vectran fiber over Kevlar for ballistic protection. Vectran (multifilament polyester-polyarylate yarn spun from liquid crystal polymer) is supplied by Houston, Texas-based Kuraray America Inc.

Bigelow is said to be in talks with NASA about adding inflatable modules to the ISS and plans to launch the Sundancer in 2014. Three launches will place two Sundancers and a BA-330 into orbit.

Earlier this year, Boeing received $18 million in NASA CCDev funds to begin preliminary development of a crew module concept, a possible means to transport space station crews and other Bigelow clients to the LEO stations. Bigelow is working with Boeing Space Exploration as a subcontractor on the project, providing additional funding and development support. Designated CST-100, Boeing’s crew module will be compatible with multiple launch vehicles, capable of carrying a mixture of crew and cargo, and based on the company’s previous work: “The tight development time line and focus on cost containment … will put more emphasis on the use of proven systems that require little or no unique development,” says Tom Andrews, Boeing’s structures design lead for CCDev, based in Huntington Beach, Calif.

Although composites will contribute to program success and are under consideration for primary structure to reduce weight and cost and boost performance, Andrews says such benefits must be weighed against the fact that “the space environment presents challenges that are not there with nonspace systems.” These include atomic oxygen, which can degrade unprotected composites, and the impact of micrometeorites or orbital debris. “These challenges require additional scrutiny above and beyond past human-occupied spacecraft experience with metallic material systems.”

With the help of Bigelow, Boeing is taking a NewSpace approach to CST-100 development — one that’s quicker and more cost-effective. Bigelow’s development schedule calls for a series of test flights in 2014 with commercial operation to begin in 2015 — a year earlier than NASA’s launch target in 2016.

Bigelow is marketing principally to sovereign nations and corporations. Reportedly, a 30-day stay on its station would cost $25 million per person. With a four-year commitment, a six-person module can be leased for slightly less than $395 million per year. Bigelow is expanding its Nevada manufacturing plant by 185,000 ft²/17,187m²) to enable mass production.

Reaching space together

Time alone will reveal whether or not these programs are viable and sustainable. Much will depend on the U.S. government’s ability to provide funding and the willingness of researchers, communications companies and tourists to foot the bill for suborbital trips and orbital insertions. Most certain is that, henceforth, composites will play a significant role in whatever transpires.

In recent testimony before the Senate Commerce, Science and Transportation Committee’s Subcommittee on Science and Space, Orbital’s senior VP Frank Culbertson echoed the confidence common to legacy contractors and NewSpace racers alike. “U.S. industry, given the right conditions, relationships and investments, should be able to develop and demonstrate safe and reliable crew transportation systems for International Space Station support by 2015,” he predicted, but warned that to do so, New-Space and NASA must yield autonomy. “I do not envisage commercially provided crew services being conducted entirely by industry with a hands-off approach from NASA. Nor can these commercial services be provided efficiently with traditional levels of government involvement and oversight at every turn.”

FARO Technologies Inc.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreBio-based epoxy, recycled materials increase sustainability of all-terrain snowboards

Aiming for a smaller environmental footprint while maintaining high performance, Salomon’s Highpath snowboard line incorporates bio-based epoxy, glass and basalt fiber stringers and recycled materials.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreRead Next

Boeing, SpaceX picked to develop crewed spacecraft for NASA

Boeing will get $4.2 billion and SpaceX $2.6 billion to develop spacecraft transport U.S. crews to and from the International Space Station.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More