Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. For parts that will be produced in low quantities and can be cured at ambient or low temperature, or for prototype parts, where tight control of dimensional accuracy isn’t of prime importance, materials such as fiberglass, high-density foams, machinable epoxy boards or even clay or wood/plaster models often are suitable. Additively manufactured or 3D-printed tools, using polymers, are also becoming more common for both prototype and production parts. Tooling costs and complexity, however, increase as the requirements for part performance and/or finished surface aesthetics become more exacting and the number of parts to be produced increase. High-rate production tools, for example, are generally made of robust metals that can stand up to repeated cycles and maintain good surface finish and dimensional accuracy. The molds in which high-performance composite parts are formed can be made from carbon fiber/epoxy, monolithic graphite, castable graphite, ceramics or metals (typically aluminum, steel and alloys of the same). In all cases, each material offers unique capabilities and drawbacks.

Sometimes called hard tooling, metal tools, although relatively heavy and expensive, are able to withstand many thousands of production cycles. The most durable, but also most costly, are made of high-performance steel-and-nickel alloys, such as Invar. Because few composites manufacturers have the equipment necessary to machine and polish metal tools — particularly Invar — they often require the services of a toolmaking specialist.

Composite tools, sometimes called soft tooling, are more easily constructed than metal tools and, because they are made from materials similar to those the composite manufacturer will use for the part, they can be made in-house. But as the “soft” designation suggests, they are more vulnerable to wear, and they typically find service in relatively low-volume production. However, several tools can be made with composite materials for less than the cost of a single hard tool. This makes somewhat larger volumes affordable. Like those made on hard tooling, parts made on composite tools can be cured in an autoclave or oven, or by integral heating, in which heating elements are placed inside the tool.

Materials for CTE management

A key issue with tooling for composites is the phenomenon of coefficient of thermal expansion (CTE) mismatch. Here, composite tooling has the advantage over metals. Composite tools made from tooling prepregs have a CTE close to the part CTE. During cure, shrinkage and thermal expansion of the tool and part will be very similar. This helps maintain the part’s dimensional accuracy.

Most metal tool materials and the composite materials in the parts they form are mismatched in terms of CTE. C-20 steel and aluminum are common choices for metal tools because they are less expensive and usually involve shorter lead times before delivery vs. high-performance alloys. However, during heated cure, the CTE mismatch between the less-expensive metal tool materials and the composite often is too extreme for use in molding close-tolerance composite parts. Only the higher-priced metal alloys offer closer CTE matches. For example, Invar — alone among tooling metals — offers a CTE very near to that of carbon fiber composites. For that reason, it has been the perennial choice for parts that must be manufactured to extremely tight tolerance. But Invar also is the most costly tooling material and, especially when it is used to large parts, the sheer size and weight of the tools makes them difficult to handle. In some cases, however, the heat-caused expansion of steel and aluminum tools during cure cycles, can be used to advantage in tooling design, to purposely compress and consolidate part elements (read an article about a complex, multi-part tool that takes advantage of metal expansion in “SQRTM enables net-shape parts”.)

This production composite tool was made with carbon/epoxy cured at relatively low temperature, then subjected to a freestanding postcure at up to 200°C. This relatively low-temperature curing regime allows for the use of more cost-effective master materials, which reduces overall tool cost. Source | Ascent Tooling Group

Extending tool life expectancy

Aerospace industry manufacturers, in particular, have long expressed a desire for carbon fiber tooling materials that can withstand thousands of autoclave cure cycles, like Invar can. To increase the durability of composite tooling, several suppliers offer hybrid tool designs that combine, for example, a thin Invar facesheet with a composite backup structure, or a carbon foam core with a composite facesheet (see “Cutting the cost and time of tooling for composites”).

Technologies have evolved to compete with Invar in the realm of durability but do so at a fraction of Invar’s weight and cost. Janicki Industries (Sedro-Woolley, Wash., U.S.), for example, has produced nearly void-free, 300-ply bismaleimide (BMI) laminates using resin infusion, which enabled the company to produce billets of BMI/carbon composite that can be CNC-machined into precision tooling that is cheaper and one-fifth the density of an Invar equivalent. Janicki is using this technology for aerospace rib, spar and stringer tools, where the parts will be autoclave-cured, high-temperature epoxy and carbon fiber. BMI greatly extends the tool’s service life compared to epoxy, which typically cannot withstand cycling up to 177°C every few days during production runs that can extend to years.

Another high-performance tooling product in this category is HexTOOL from Hexcel (Dublin, Calif., U.S.). A machinable carbon fiber/BMI composite tooling material, it comprises BMI prepreg strips that are randomly chopped and distributed onto a release paper to form a thick, tacky mat. After layup and cure, it can be machined like metal, has a CTE that matches carbon/epoxy parts and can survive 500 autoclave cycles, all with a build time and cost comparable to existing alternatives.

Other high-temperature technologies touting longer tool life include 3M Advanced Materials Division’s (St. Paul, Min., U.S.) Fortified Tooling Prepreg (FTP) BMI and Airtech International Inc.’s (Huntington Beach, Calif., U.S.) Beta Prepreg tooling system, which incorporates Henkel (Rocky Hill, Conn., U.S.) benzoxazine resin. Both are autoclave-curable, and their formulators claim that they exhibit lower resin shrinkage, compared to epoxy, and excellent machinability.

Carbon/BMI for high-rate tools: For high-rate composite production tooling, a carbon/bismaleimide (BMI) material combination can be specified. A carbon/BMI tool is shown here, after postcure, as it is machined to final tolerance. Source | Ascent Tooling Group

Distributed by TenCate Advanced Composites (now Toray Advanced Composites, Morgan Hill, Calif., U.S.) 3M BMI TC-44 Si uses a 40% (by weight) loading of microscopic silica particles to reduce through-thickness CTE by 15%, linear CTE by 40% and linear cure shrinkage by 50% compared to comparable unfilled, autoclave-cure BMI prepreg. Together, these improvements reduce thermal stresses and part distortion and are expected to significantly limit springback (a part’s tendency to deviate from the molded shape due to cure shrinkage in the composite). Other benefits include better scratch resistance and fracture toughness, reduced microcracking, and 40% lower exotherm per mass for much improved thermal management — especially important for thick part fabrication. Airtech is claiming similar performance and production benefits for its Beta Prepreg, which uses benzoxazine’s unique chemistry instead of nanosilica, and has demonstrated a 70% reduction in springback. Plus, its six-month ambient storage life basically eliminates frozen storage requirements for tooling projects and reduces shipping costs. Users, so far, report that the material has greater tack, which reduces layup time and requires fewer intermediate debulks. Airtech says BetaPrepreg is cost-competitive with BMI but contends that its performance and fabrication efficiency can tip the scales in its favor.

Another alternative to traditional metals is a toolmaking process that uses a nickel vapor deposition (NVD) process to produce relatively thin nickel-shell tool faces, which are supported on a backing structure. The NVD process can produce tools that achieve high dimensional fidelity, and the nickel-shell toolface exhibits low CTE, long useful life and, because it is far less bulky than machined metal tools, weighs less and facilitates faster mold heating and cooling than do other materials. NVD specialist Weber Manufacturing Technologies Inc. (Midland, Ontario, Canada) produces nickel-shell tools for applications that range from automotive body panels to aircraft interior storage bins.

Surface Generation Ltd. (Rutland, U.K.) offers a sophisticated approach to heated molds. Its Production to Functional Specifications (PtFS) process technology encompasses a range of active thermal management options. Tools can be designed such that mold temperatures can be dynamically controlled to the exact requirements of individual regions or zones in a part and progressive stages of the forming and curing process. Isolation and individual control of these regions enables manufacturers to continuously, and very rapidly, adapt each zone’s heating and cooling levels in real-time, optimizing part quality and maximizing throughput.

EireComposites Teo. (Irish Composites, County Galway, Ireland) has developed a patented technology for integrally heated tools called MECH (Mould Efficient Cooling and Heating). The resulting mold features electrical heating elements that are embedded using an aluminosilicate-type ceramic cement, which offers low CTE, density, thermal mass and electrical conductivity. Carbon fiber reinforcement bolsters the ceramic’s low tensile strength. Polyetheretherketone (PEEK) high-performance thermoplastic polymer is used as an adhesive layer between the carbon fiber and the ceramic. The tooling can be built on inexpensive patterns because the ceramic becomes rigid at 60°C. The tooling is removed from the pattern after this initial lower-temperature cure and then processed to full temperature (200°C to 400°C) via a freestanding postcure. The in-plane CTE measured for a tool at least 15 mm thick is reportedly less than 5.0 x 10-6/°C, which, according to ÉireComposites, is generally accepted as a “matching value” for most glass and carbon fiber composites. Using an electrical wattage density of 10 kW/m2, this type of tool surface can be heated to 200°C in less than 10 minutes.

Embedded resistance wiring or other electrical means are not the only way to integrally heat tooling. Tooling with built-in ducts that heat and cool using forced air has been used in the aerospace industry for decades. The wind industry has infused layups in heated molds for years, commonly using fluid conduits. Using heated and cooled liquids for molding composites first gained traction with VEC Technology LLC’s (Greenville, PA, US) Floating Mold technology and, more recently, with Quickstep Holdings Ltd.’s (Bankstown, NSW, Australia), “balanced pressure fluid molding” technology. Other systems include Techni-Modul Engineering’s (Coudes, France) self-heated tooling that features a fluid-circulation system. These tooling approaches can use a variety of media (oil, water or metal-based fluids) to impart temperature control to heat thin, lightweight tooling shells, and they are less costly than the conventional metal tools used in RTM. Another effective approach, offered by Regloplas Corp. (St. Gallen, Switzerland and St. Joseph, Mich., U.S.), combines a system for heating plumbed molds with hot, pressurized water, while the molds are inside an autoclave during the cure cycle. The pressurized-water unit heats the tool directly. Therefore, it transmits heat to the part much more quickly and efficiently than an autoclave’s onboard convection heating system, which heats the air within the vessel, rather than heating the tool directly. Therefore, the autoclave is used primarily to provide the pressure that consolidates the layup. As a result, the overall energy expenditure during cure is typically much reduced. Heated fluid systems for plumbed tools are also offered by Single Temperature Controls Inc. (Charlotte, N.C., U.S.) and Westminster Solutions Inc. (Plainfield, Conn., U.S.).

Commercialized tooling design software is reducing the time it takes to model and manufacture a tool — including backup structure — by 80% in some cases. Available inspection systems give tooling suppliers and fabricators a way to verify a tool’s dimensional accuracy prior to and during production. In recent years, a variety of low-cost modeling materials that maintain dimensional stability at higher temperatures have made inroads into traditional toolmaking.

A growing trend is the use of additive manufacturing (3D printing) to rapidly create prototype tooling, fixtures and jigs and even layup tools for composite parts, which enable faster design cycles. The growth of larger and more robust 3D printing infrastructure as well as higher-temperature resins and carbon fiber reinforcement will accelerate this trend. In addition, large-format additive manufacturing continues to develop especially for next-generation aerospace applications: “Big additive machines tackle large molds.”

For more on evolving tooling technologies in 3D printing, OOA infusion and thermoplastics see: “Tooling technologies positioned for speed, control.”

Mold preparation pays

No matter the tooling material, the importance of mold release agents cannot be over-emphasized. Releases create a barrier between the mold and part, preventing part/mold adhesion and facilitating part removal. For open molding, most releases are either waxes or are based on polymer chemistry. In some cases, release papers are applied to the mold. Of these, most are polymers in solvent-based carrier solutions, such as an aliphatic hydrocarbon blend. Some manufacturers prefer naphtha-based releases, which have longer shelf lives and faster evaporation rates and are considered to be less damaging to composite tool surfaces. Increasingly strict emissions regulations have encouraged development of water-based releases, which produce no volatile organic compounds (VOCs) and clean up more easily, with less risk of skin irritation.

Semi-permanent polymer mold release systems enable multiple parts to be molded and released with a single application, in contrast to paste waxes, which need to be reapplied for each part. Semi-permanent releases — preferred for better control over VOC emissions — are formulated specifically to meet the needs of resin transfer molding (RTM) and other closed mold processes.

Internal release agents, added to the resin or gel coat and used instead of or in addition to external agents on the mold surface, further reduce emissions, and have negligible effects on a part’s physical properties and surface finish. Internal release formulations are required for pultrusion processing because the part is pulled continuously through the die, allowing no opportunity for intermittent application of external releases to the die surface.

Fixturing, trimming, drilling

In terms of tooling fixtures, typically a major expense for very large composite parts that require post-cure trimming or drilling, many approaches are possible, including aluminum or steel structures that hold a part in place for post-cure CNC machining. CMS North America Inc. (Caledonia, Mich., U.S.) is one of several companies that supply a universal holding fixture that can quickly conform to a part shape and hold it securely for post-cure operations.

Janicki has developed composite trim and drill fixture production techniques that save cost vs. metals. In contrast to large metal structures, Janicki achieves the same tolerances using its low-cost tooling technology — wood structure with machined putty and fiberglass — but at a much lower cost. This is possible because of the way it “clocks in” the milling head’s positional accuracy. Janicki uses the tool’s pattern again to make these low-cost trim-and-drill fixtures. Thus, the means to make the fixture is paid for in the tool fabrication, which results in significant savings.

This article was originally published 3/23/2016, updated 7/5/2022

Related Content

Belzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MorePittsburgh engineers receive $259K DARPA award for mussel-inspired underwater adhesion

The proposed META GLUE takes inspiration from hydrogels, liquid crystal elastomers and mussels’ natural bioadhesives to develop highly architected synthetic systems.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MoreRead Next

Demonstrator shows potential for graphene-enhanced composite tooling

U.K.-based collaborative project demonstrates lower-cost, graphene-enhanced composite tooling for aerospace use.

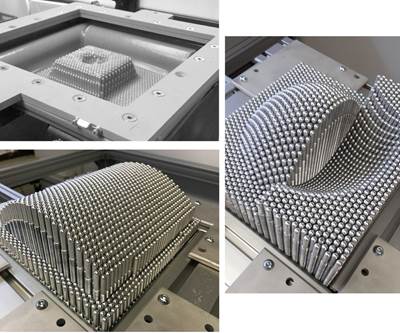

Read MoreDYNAPIXEL: automated, reconfigurable molds

CAD-driven system cuts time for design iterations, enables cost-effective customized jigs and molded parts.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)