Two-stage tape layup: Access cuts/Atlas 2 lays up

A legacy 1980s technology builds visionary Dreamliner wingskins.

When Fives Group, headquartered in Paris, France, acquired the Cincinnati Milacron and Forest Liné machine tool brands from MAG IAS LLC in 2013, it took on the only two-stage composite tape-laying system in the industry. Access (Automated Composite Cassette Edit-Shear System) and Atlas (Automated Tape Layup System) were the brainstorm of composites pioneer W. Brandt Goldsworthy and his team at the former Goldsworthy Engineering (Torrance, CA, US) in the 1980s. The two-stage system was originally designed by the Goldsworthy team under contract to Forest Liné (Granby, QC, Canada) now part of the Fives Group.

The concept of a two-stage approach to tape laying was Goldsworthy’s solution to a common source of aggravation and downtime in the youthful days of composite airframe development. Industry attempts to replace hand layup with automated equipment were plagued by frequent failures of automated devices to cut through all strands of tow in a prepregged carbon fiber tape. The tape layup head would lay tape to the end of its path, cut the tape, and then shift to its next path, or course, as it assembled successive plies. But if even one small strand of fiber, or string, had not been totally cut through, that attached string would tear the laminate when the head shifted course. In addition to downtime, this resulted in considerable scrap, and this at a time when Steve Albers, product manager – composites for the Fives Group, recalls, “the cost of raw material was close to US$300/lb.” He points out that “carbon prepreg is still pretty expensive, and even now, taking the cutting off line and allowing the machine to continue its layup makes the machine more productive.”

Cutting reliability

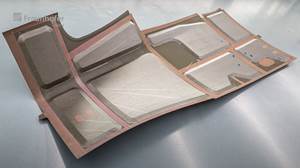

In essence, the two-stage system offloads the issue of cutting reliability from the tape layup head and places that responsibility onto the offine Access cutter. Access precuts 6-inch/150-mm unidirectional prepreg tape to preprogrammed shapes, or patterns, via an ultrasonic cutting system. The Access system only carries 6-inch-wide tape, so it is typically used to make all the complex cuts for a layup. The cut shapes are rolled up onto a 25-inch (6,350 mm) diameter cassette spool in the specified design sequence. The material moves through the Access process in a forward direction, although the cutter can reverse as needed to cut a particular shape. When full, the cassette — typically weighing about 40 lb/18 kg — is removed from Access and installed on the 6-axis Atlas automated tape layer (ATL), which then lays and compacts the patterns on the part tool to fulfill the prescribed fiber architecture and ply schedule. The procedure for removing an empty cassette and replacing it with the next cassette typically requires no more than 5 minutes.

Today, cutting reliability on ATL systems has been greatly improved by better programming and cutting technology. But the two-stage system is still used as a means to avoid the risk altogether. “Cutting issues on tape laying machines today are mostly driven by dry fibers or loose fibers on the edges of the material. So attached strings sometimes, unfortunately, still occur, but it’s significantly better than it was 30 years ago,” says Robert Harper, Fives’ director technical sales, proposals and applications engineering.

Design/manufacturing advantages

“Probably the biggest advantage of the two-stage system is the throughput of the Atlas machine, itself, which can be 30% or 40% greater compared to other tape-laying equipment, because the machine is not spending time cutting the material,” Harper says. On the other hand, the two-stage system calls for close inventory control of the material that has been pre-cut, especially since the material is usually an epoxy matrix prepreg, which must be kept cold to avoid premature curing or moisture contamination of the resin: The prepreg comes out of the freezer, is custom cut for a specific part, and must be either put directly onto the Atlas machine or back in the freezer, and closely tracked until it is used,” he says.

Although the Access cutting system adds a second machine, a separate process, additional inventory control and an operator to manufacturing costs, one Access unit can serve as many as three Atlas tape layers. And, Albers points out, “no time is lost for complex cuts or an un-cut string” when laying precut tape. There also is typically less downtime and less scrap compared to standard tape laying systems.

One significant design change has been made since the first Access. Originally, the prepreg tape would be cut away from the backing paper, cut to shape, and then the cut piece would be deposited on a new piece of backing paper and sandwiched between the new backing paper and a plastic film. This created problems with some of the cut patterns (courses), because they tended to move laterally, Harper says, shifting out of alignment on the new backing paper, so they were not centered in proper sequence on the cassette. The operation was, therefore, redesigned, so that the material now remains on the original backing paper throughout the process. Further, a section of tape is actually removed between all cut shapes on the backing paper, allowing a space between the courses. “You lose a little scrap efficiency this way, but it gives us much better control of the end-placement,” Albers says. A servo control on the cutter prevents the system from cutting through the backing tape, ensuring the precise cut depth. “And the operator knows for sure there’s no stringer that’s attaching one course to the next,” Albers adds. This new design is called Access and Atlas 2, and it differs from the design in Goldsworthy marketing VP Glenn Ewald’s original paper on the system, titled "Access/ATLAS II, Two-Stage Tape Placement System," which can be accessed online here.

According to previously published information, Mitsubishi Heavy Industries (MHI, headquarters, Tokyo, Japan) has installed the two-stage Access and Atlas 2 system in its Nagoya Aerospace Systems Works (Nagoya, Japan) for manufacture of composite wingboxes for Boeing’s 787 Dreamliner. MHI increased its production rate of the 787 wingsets in early 2016, with 14 shipsets per month targeted by the end of the decade. Material for the wingskins was identified as a prepreg tape made by Toray (Tokyo, Japan), from Toray’s polyacrylonitrile (PAN)-based T300, T700G and T800S carbon fibers preimpregnated with BMS 8-276 350°F (177°C)-cure toughened epoxy made by Toray Composites (America) Inc. (Tacoma, WA, US). It is applied in 6- and 12-inch (152-and 305-mm) widths.

Patrick Rousseau, key account manager – composites for Fives, names Airbus (Toulouse, France), Fuji Heavy Industries Aerospace Co. (Subaru, Japan), Daher (Toulouse, France) and Bamtri (Beijing, China) as other key Access/Atlas users.

Cassette and bulk layup

In addition to carrying the Access cassette with the 6-inch precut tape, the Atlas 2 layup head has the capability to apply bulk from a 12-inch wide roll of prepreg, and to cut that tape on the fly. “So the head is capable of laying both cassette and bulk tape,” Harper confirms.

The spaces provided between each of the cut shapes — which are positioned in serial arrangement along the length of the cassette roll — is another very advantageous feature of the Access pre-cut tape for combined bulk-cassette layups, Albers continues. “As an example, consider a large part that might have full ply courses made from bulk 12-inch tape, with doublers and very small courses in pre-cut plies in the middle. This is a situation that is reportedly ideal for Access, giving the operator confidence that each separate course is cleanly separated from the ones before and after it. It ensures against creating a problem when a complex course is laid in the middle of a large-part layup. Because if you do have a problem out there, it is very difficult for a worker to get out to the middle of a very large part in order to repair the layup.”

The Atlas 2 typically completes one bulk course, lifts off the surface and rotates around to layup the next bulk course, or switches to the Access cassette to lay its complex cut shapes.

“The machine is programmed to do what is most efficient to complete the part. Our programming software calculates the most efficient ply schedule,” Harper says. For one ply, all the bulk may be laid first, and then the ply filled in with the shorter cassette courses. For another ply, one or two cassettes may be laid first, then the head switches to lay bulk for the rest of that ply. The software also determines when to lay tape in axial or off-axis directions. “As the courses get shorter,” Harper says, “it is faster to move the major axes of the Atlas machine as opposed to rotating the head. The software automatically calculates that, as well.”

The Fives Group is transitioning software for controlling all its fiber placement and tape laying machines — including Access/Atlas 2 — to Cincinnati Milacron’s Advanced Composite Environment Suite (ACES). “We will have one common programming system for all of the Fives brands,” Harper says.

Complex compound curvatures

Another historic source of aggravation in automated tape laying is the tendency of courses to wrinkle or slip on a complexly curved mold surface, again causing expensive downtime. The ability to lay pre-cut tape into the complex curvatures of a wing mold, for example, is an additional and significant advantage of the Access cutting. Direct layup of specific precut shapes, typically in short lengths, designed for specific curvature areas, has proved a welcome solution. Albers explains, “The Atlas 2 machine features a full six-degrees-of-freedom vehicle, so the debulking pressure is always applied normal to the curvature of the layup surface. This provides superior lap/gap performance on highly contoured layup surfaces.”

Continued impact of an early innovation

ATL technology struggled through many difficulties — in both production and control — as it came of age, and airframe manufacturers and suppliers worked closely together to find solutions, foretelling automated production of composite airframe elements as a realistic and worthwhile goal to replace, or supplement, hand layup or other, traditional airframe materials. Access/Atlas 2, built on an early but elegant, far-sighted design that has endured the test of time, still finds application on one of the most significant composites applications in the 21st Century. But it is more than a reminder of Brandt Goldsworthy’s early contributions to composites and of how legacy technology advances can prove relevant for visionary production. The system’s continued use and the success of automated tape laying itself is a testimony to the value of cooperation and communication between materials and parts manufacturers in any industry, something often missing in today’s increasingly complex programs and digital/software-based design and manufacturing systems. But it’s something that, in today’s increasingly global environment, will be more important than ever.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreOptimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)