Automated preform process boosts properties and cuts cycle time

Fiber Patch Placement (FPP) achieves optimized fiber orientation for up to 150% increase in stiffness and reduced cycle time, weight and material waste.

As promised from my blog in July, here is a more in-depth update on Cevotec’s development of the Fiber Patch Placement (FPP) process. FPP was originally developed by Airbus Group (previously EADS Innovation Works, Ottobrunn, Germany) and has been further developed by Cevotec (Garching near München, Germany), a spin-off from TU München (Munich, Germany).

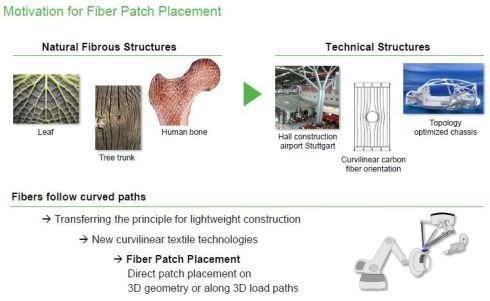

FPP is an automated process that builds complex part preforms by placing unidirectional CF patches along calculated load paths, achieving very efficient structures like those seen in nature. SOURCE: Cevotec.

FPP takes unidirectional carbon fiber (CF) patches (e.g. 20-mm wide by 60-mm long by 0.1-mm thick) and precisely places them along calculated load paths to create highly optimized preforms. The automated process is able to build very complex structures quickly. For example, working with a leading medical device OEM, Cevotec is using FPP to build a one-piece CF orthosis preform in 30 minutes that previously required more than 40 separate pieces of prepreg and 1.5 hours of hand lay-up. Cevotec is currently using HTS45, IMS65 or UTS50 carbon fiber from Toho Tenax Co., Ltd. (Tokyo, Japan) and T300 and T700 fibers from Toray (Tokyo, Japan) in tapes from 15-40 mm width and 60-180 g/m² areal weight with Spunfab thermoplastic web applied as binder. The preforms are subsequently molded using standard vacuum infusion or resin transfer molding (RTM) processes. Cevotec has worked with Airbus to advance the FPP automated robotic hardware, software and process chain to speed up the patch-based laminate generation and also to make it more stable and flexible.

Cevotec preforms and samples made using FPP. SOURCE: Cevotec.

Faster, more flexible production

Co-founder Thorsten Groene describes Cevotec’s work to ready FPP for broad commercial application. “We have improved the robotic arms to optimize their movement and cooperation. We are also using faster pick and place units with nominal 160 picks/min, which will speed up the placement process.” According to Groene, a new FPP line, operational in March 2016, will be capable of longer patches as well as using wider and thicker tapes. “Thickness influences both the process speed and the mechanical properties of the preform,” he notes. Higher performance parts will use thinner tapes, while the challenge for industrial and recreational product preforms will be balancing thickness vs. properties. The new production line will also build bigger parts due to a wider placement window (2500-mm x 1500-mm x 500-mm). “We have a larger 6-axis robot to hold heavy and large preform tools,” says Groene. While the initial production line could produce preforms at speeds of up to 500 grams/h, the new FPP line will expand greatly to 2000 grams/h of dryfiber mass throughput.

Of course, with new hardware improvements, the software must be updated accordingly. “We can now combine longer and thicker patches with small and thin patches,” says Groene. The new line will also enable thick-walled parts and improve the ability to form more convex and concave surface structures. “We have developed machine control adaptations that enable this greatly improved production flexibility while avoiding bridging effects during placement.” Cevotec’s team has also completed a software suite that enables virtual product development, seamless from product conception to part production. “We have full orientation control of every patch placed,” says Groene, “and can vary thickness locally by numerical optimization analysis. No material is placed where not needed.” He says that compared to stacking and draping fabric or even using automated layup technologies, FPP’s patch-based approach is a completely new category. “This approach is best able to utilize the opportunities provided by anisotropic materials,” he asserts. “But it requires sophisticated software in order to construct what is ideally possible.”

So what is possible? Groene says FPP can produce highly optimized preforms with 150% increased stiffness and up to 50% less scrap vs. continuous fabric preforms. For example, Cevotec has produced a CF snowboard reinforcement which achieves separately optimized bending and torsional properties as well as precise longitudinal loads with a zero material scrap during manufacturing. “The layer of continuous fibers the manufacturer was previously using does not provide the properties needed exactly and adds weight.” FPP reduced that weight by two-thirds and simplified the layup and fabrication process while increasing the value of the product and the price the manufacturer can command.

FPP can also be used to provide local reinforcement for fastener holes, increasing bearing strength of bolts by 25%. SOURCE: Cevotec.

Build-ups for bolt holes

FPP can also be used to reinforce holes for mechanical fasteners. “The objective is to build structures that are as thin and light as possible," says Groene. "However, drilling holes into structure requires handling the resulting shearing stresses and providing sufficient bearing strength for the fasteners.” Ideally, the best solution would be to reinforce locally vs. having to build a thicker overall structure. However, local reinforcement is not typically efficient in conventional high-volume production. Groene says FPP is well-suited for high-volume production and enables patch-based layups with a radial orientation of fibers in every direction, vs. just a few orientations with conventional layups. The FPP reinforcements are inherently scarfed so that the center portion is thicker and the edges are thinner. Groene says this provides effective load transfer into the surrounding laminate, increasing the bearing strength of bolts by 25% compared to conventional layups for the same part. With FPP, it is easy to produce complex shapes needed to reinforce local areas and apply the heated FPP reinforcements onto existing layups. This technology is also well-suited for producing repair patches, which Groene says is definitely within Cevotec’s focus for the future.

Turnkey solutions

Groene points out that Cevotec’s capability extends beyond just designing and producing FPP patches and parts. “We are offering a one-stop shop, providing manufacturing companies with a turnkey solution that includes software, hardware and pre-production assistance.” He gives the automotive industry as an example. “We are based in Munich with great automakers on our doorstep. We are in touch with these companies, and see very interesting applications for FPP in high-end car models. However, we also see that other manufacturers may take a less capital-intensive approach which would fit well with FPP.” In other words, FPP could help achieve some of the tailoring and improved performance in a way that demands less in-house complexity for the manufacturer. “We are also offering a new carbon fiber look which is already interesting to companies using carbon fiber but which want new aesthetics.”

FPP offers a new aesthetic for CF parts. SOURCE: Cevotec.

Discontinuous fiber is the new black

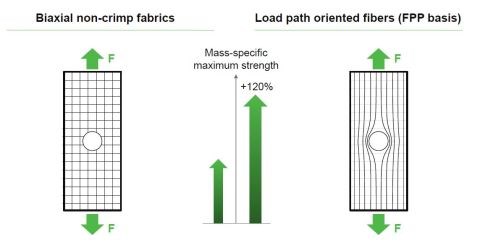

“We are breaking the paradigm that carbon fiber has to be continuous,” says Groene. Testing of a tensile open-hole specimen with conventional (LEFT, below) and FPP-based lay-up (see RIGHT, below) showed a 120% increase in mass-specific max. strength with FPP. Cevotec has verified this through tests on various geometries with curved load paths, confirming increase of specific stiffness and strength as high as 150%.

FPP allows following a curved load path, such as around bolt holes, for a 120-150% increase in specific strength. SOURCE: Cevotec.

Groene concedes that discontinous fiber laminates in conventional tensile-based specimens do have a 20-25% knockdown in strength vs. continuous fiber, “but if the load path is curved we can follow it and gain massive performance, more than compensating for this knockdown." He notes that with conventional laminates, a 15% deviation in the angle of the fiber vs. the load can produce an 85% drop in strength. "We also do not put fiber where it’s not used," he adds, "so the weight is much more optimized.” Groene explains that with the part geometry and loads defined, Cevotec can perform finite element analysis (FEA) calculations to identify how the load path will run through the part. “We then use this information to orient our fibers along these paths.”

Groene acknowledges that Cevotec has a long road ahead in gaining widespread commercial applications. However, the company has received a lot of interest so far and has developed a plan that targets “low-hanging fruit” first, via medical and sporting goods applications, while developing partnerships for longer-range, larger applications. “We are still seeking customers and partners to develop parts as well as investors,” says Groene, “but we are confident in FPP’s future and the opportunity for lower cost and greater efficiency that it offers for manufacturing with composites.”

Related Content

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

Airbus A350 Update: BRaF & FPP

EADS Innovation Works pursues qualification of Braided Frames for the A350-1000 fuselage and develops Fiber Patch Preforming for complex local reinforcements.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More