Carbon fiber Hyperloop design to transform transportation

A group of Carnegie Mellon University students will test out their carbon fiber pod design during a competition at SpaceX’s headquarters in August.

Imagine the potential to travel from distances such as Los Angeles to San Francisco in 30 minutes. It’s not science fiction, it’s not a concept that won’t happen for another 50 years— it’s on track to be our new reality, thanks to Elon Musk and some of the brightest university students around the world. Back in 2013, Musk first unveiled the idea for a new high-speed ground transport system, named Hyperloop. It would feature a network of tubes that could span hundreds of miles. In order to accelerate the development of Hyperloop, Musk announced a competition that called on universities to compete and build the best Hyperloop pod.

For college students that want to make a difference in the world, it’s a dream project. This past January, Texas A&M University sponsored a Design Weekend where more than 100 teams competed to become semi-finalists in the Hyperloop Competition. One of the finalists from that competition includes a group of Carnegie Mellon University students whose design is “solid and impressive,” according to SpaceX. Carnegie Mellon Hyperloop is an interdisciplinary team of more than 50 engineers, designers and business students with the vision of taking the pod all the way through the competition to win.

The 30 different student teams, including the group from Carnegie Mellon, will have the chance to test out their pod designs on the one-mile test track outside of SpaceX’s headquarters in Hawthorne, Calif. in August.

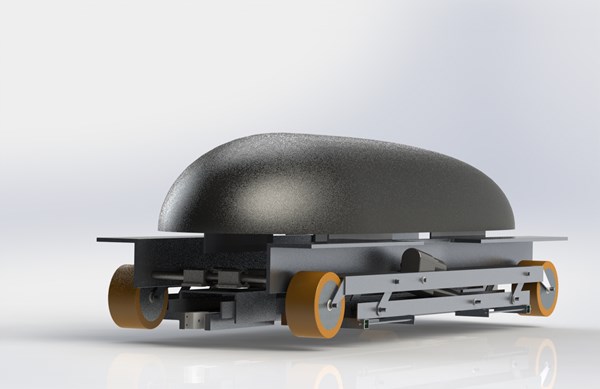

I talked with some of the students from Carnegie Mellon as their design includes a carbon fiber shell, which encloses the various components of the pod. The dimensions of the carbon fiber structure are 8 foot by 3.5 foot by 3 foot. Here's a photo of the design:

“Being a student team, this is the first time the team members are building a huge carbon fiber shell and a big challenge is to make the high-quality mold for the carbon fiber layup,” said Siddharth Alampally, graduate student of the Mechanical Engineering Department at Carnegie Mellon. “This is a process that needs patience with such a big structure.”

“We decided to build a carbon fiber-reinforced plastic structure because it has a very high strength-to-weight ratio and we chose the process of resin infusion as it allows us to manufacture a custom shape with high-quality,” he said.

Other components of the pod include maglev, magnetic levitation, which is not used in transportation anywhere in U.S. and bringing these concepts to reality is another big challenge.

“In our efforts to design a truly scalable Hyperloop pod, we find ourselves dealing with questions that even industry experts have trouble answering,” the students wrote on their Crowdfunding page. “The most pressing issue is that of the air bearings we intend to use. Even the most promising alternative for our levitation system, an air caster style bearing, has never been tested at the extreme conditions that have been proposed for the final event.”

The situation requires that they carry out primary research and prototyping by putting together a test rig that artificially simulates these conditions for the Levitation assembly. The group plans to complete the pod by the last week of July so that it gives more time for testing.

Wish the team luck for the August competition and go team carbon fiber!

Related Content

Composite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

Read MoreNew Flyer selects Hexagon Purus H2 tanks for fifth consecutive year

Type 4 tanks will continue to be supplied for the mass mobility provider’s Xcelsior Charge FC fuel cell electric transit buses.

Read MoreHexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreComposites reinvent transportation

Celebrating National Composites Week, CW shares ways in which composites continue to evolve mass transit.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More