Composites in architecture: Educating for growth

Nexus between architecture/design and performance sailing explores the opportunities that composites offer for building and construction.

Top left to right: Univ. of Southern California (USC) Performative Composites workshop; composite cladding designed in partnership with Snohetta and fabricated by Kreysler & Associates for new expansion at San Francisco Museum of Modern Art (SFMOMA) eliminated 1 million lb of steel; USC and UCLA students gain hands-on experience with composites. Bottom left to right: Greg Lynn explored new shapes integrating interior structure and furnishings in the GF 42 carbon fiber trimaran; Lynn’s Room Vehicle (RV) PROTOTYPE House, a cored carbon fiber monocoque weighing only 50 kg. SOURCES: USC Architecture, Snohetta (overlay CompositesWorld), Greg Lynn.

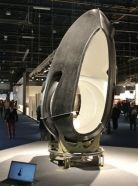

Last month, I attended an event hosted by the University of Southern California’s (USC, Los Angeles, CA, US) School of Architecture titled “Performative Composites: Sailing Architecture.” Organized by USC School of Architecture professor Geoffrey von Oeyen, the event centered around the first exhibition of renowned architect Greg Lynn’s project to design and build the GF 42, a 42-ft carbon fiber foiling trimaran (three-hulled sailboat which “flies” above the water on thin foils protruding down from the rudder and keel). That project served as a vehicle for introducing architects and students to composites and how they can actualize digital designs and allow exploration of new paradigms like tension-based structures and designs which integrate structure and surface.

Left: Coupled hydro-aero dynamic computational fluid dynamics (CFD) analysis developed by Naimish Harpal of CFD Max (St. Louis, MO, US). Right: 3-D printed fiber reinforced nylon steering quadrants and rudder arms: four less pieces of metal on the boat. SOURCE: CFD Max and Greg Lynn.

Left: Lynn exploited digital and composites technologies to explore new shapes for interiors and surfaces as multifuncitional structures. Right: Traditional portholes get “punched out”, adding width to create a feel of space inside without sacrificing the performance of a narrow hull at the waterline. SOURCE: Greg Lynn.

Recognized globally as a pioneer in applying digital technology and computer numerically controlled (CNC) machinery in design, Lynn has also been a leading advocate for the use of composites in architecture. He has likewise championed composites in collaborations with BMW, Disney and others.

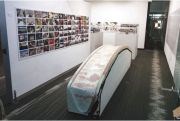

The Performative Composites event featured an exhibition which included parts and design documents from the GF 42, an actual carbon fiber composite foil from the 2013 Oracle Team USA America’s Cup catamaran, and images and design documents for the fiberglass-reinforced composite cladding fabricated by Kreysler & Associates (American Canyon, CA, US) which is currently being installed on a new expansion at the San Francisco Museum of Modern Art (SFMOMA, San Francisco, CA, US).

USC Performative Composites exhibit, featuring GF 42 models, molds, structures, photos and design documents as well as (center) a 3Di sail from North Sails and a CFRP foil from the 2012 America’s Cup Oracle Team USA foiling catamaran. SOURCE: Greg Lynn and CompositesWorld.

The exhibition was prefaced by a series of presentations reviewing how composites have been used in high performance sailing structures and how their design principles and performance benefits could be exploited for architecture, design and building construction. Speakers included:

- Greg Lynn — Greg Lynn FORM

- Bill Kreysler — President, Kreysler & Associates

- Kurt Jordan — Structural Design and Analysis, Oracle Team USA

- Fred Courouble — Courouble Design & Engineering (design team for GF 42)

- Lynn Bowser — Owner, Westerly Marine (builder for GF 42)

- Bill Pearson — Technical Director, North Sails (pioneer in thin ply composites for sails and structures, now expanding beyond marine, e.g.: sporting goods, motorsports, aerospace)

Both mornings of the two-day event featured “Composites 101” classroom lectures and hands-on workshop exercises, organized and conducted by Composites One (Arlington Heights, IL, US), CCP Composites (North Kansas City, MO, US) and Kreysler & Associates. The turnout was impressive, including both USC and University of California Los Angeles (UCLA) design and architecture students, varying from 30 to 60+ throughout the sessions on both days, with the hands-on exercises drawing the largest crowds.

My take away from this event is that architecture and design communities are hungry for information about composites and hands-on experience with them. ACMA’s Architectural Division has been trying to meet this need, spearheaded by the trio who supported this event as well as Ashland Performance Materials, which maintains the CompositeBuild website.

According to industry estimates, composites comprise less than 0.5% of the 3 billion tons of materials used in buildings annually. There is certainly room for growth. I’ve seen firsthand how interested designers and architects are in using composites. The issue is a widespread lack of education — how to design with composites and fabricate structures with them. This must be addressed before designers can use fiber-reinforced composites as cost-effective alternatives to traditional materials.

Michael Lepech at Stanford University has published a study showing that lightweight composites often outperform wood, masonry and steel, achieving a lower carbon footprint because the heavier traditional materials require more energy to manufacture, transport, assemble and support. But composites are rarely included in the Materials and Studio classes required as part of Design and Architecture programs. Why? Because design texts and tables are easier to obtain for masonry, metal and wood, as are the materials themselves, compared to composites. For example, where do these programs go to source training curricula and materials for hands-on exercises?

Relaxed — This barrier wall system came from an interest in complex curvatures supporting standardized glazing modules. Windows perpendicular to the building envelope (see arrow) provide the depth necessary to make the FRP panels self-structural. This structural facade permits reflected light while creating intimate niche spaces. SOURCE: California Polytechnic State University–San Luis Obispo.

Emerging Web — Vertically curved FRP panel units connect seamlessly into a web-like structure with unique spatial opportunities. Panels are made by covering CNC milled foam molds with fiberglass and resin, the foam providing built-in insulation. Embedded with windows, the integrated façade modules are easy to install during construction.

SOURCE: California Polytechnic State University–San Luis Obispo.

The above studio projects were completed by the Materials Innovation Lab at California Polytechnic State University–San Luis Obispo (Cal Poly SLO) with funding from Kreysler & Associates and ACMA's Architectural Division, enabling architecture and design students to become familiar with composites and work with them to explore new concepts for integrating structural support into the building envelope, which normally just provides an aesthetic wind and rain barrier.

The potential for composites in architecture, building and construction is huge. Case histories are mounting where composites are used to save millions of dollars, reduce the number of subcontractors and cut months off the construction schedule. Building codes have started to change and new systems have passed flammability and installation hurdles. However, fulfilling composites’ potential will require more education and more materials in the hands of designers and architects, especially those already developing their visions for tomorrow’s structures as they prepare to enter the workforce.

For more information on how you can be involved contact ggardiner@compositesworld.com

USC Performative Composites lecture highlights:

Bill Kreysler: The productivity of the construction industry has not doubled like most other industries — it’s actually gotten worse. Composites offer a chance to improve construction design, performance and speed of fabrication and installation. Digital technology is allowing building design to take first steps toward the efficiency seen in nature. Traditionally, buildings have been heavy structures that rely almost exclusively on compressive strength. Even the complex shapes of modern architecture are often merely torturing of traditional, heavy materials. Building codes have helped maintain this arcaneness. Structures in nature, however, often have material oriented only where it is needed to bear load efficiently. Composites can actualize new digital designs and new design paradigms, for example, shape becoming structure— e.g., monocoques. The Bing Concert Hall at Stanford University (Stanford, CA, US) uses a quasi-monocoque construction but could have eliminated steel structure entirely. The new expansion of SFMOMA was able to eliminate 1 million lb of secondary steel structure by attaching fiber reinforced composite panels as an integrated rain screen/“rippled” façade directly to a unitized aluminum panel framing system. It was also the least expensive solution.

Greg Lynn: A sailboat is a good example of a structure with multiple criteria being met with a single form. Instead of a hull, deck and cabin, the idea with GF 42 was to look at a 100% surface design, a shell construction using adhesive bonding to eliminate mechanical assembly as much as possible. This is not only light, but also more cost-effective. “I tried to explore surface minimalism by integrating components.” For example, the boat’s chine is used not only to resist cartwheeling (predicted reaction when fast foiling boat hits a wave), but also to add interior width to a hull that must be very narrow at the waterline for performance. Attachment points for hardware were also designed into surfaces. All of the furniture was designed to be multifunctional, also serving as support structure for the hull and providing storage.

Bill Pearson: North Sails operates in a space between textiles and composites. In the last 20 years it has reinvented itself twice. First, in the 1990s, it moved away from woven sails using high performance fibers like Kevlar and carbon, and embraced 3D laminate technology (3DL). This still utilized Kevlar and carbon, but is no longer woven. Instead, fibers are placed only where needed to resist loads by automated robots onto adjustable, actuated molds. However, the fibers were still laminated to mylar or other film in order to provide a solid “sheet” to resist the wind. Before that technology even saturated the market, North Sails embraced 3Di — “i” for isotropic because this technology comes very close to achieving the holy grail of sailmaking: balanced resistance to distortion in all directions. (See Donna Dawson’s article “Custom-engineered composite performance yacht sails.”) 3Di uses the same automated robotic fiber placement onto articulated molds, but the fibers are applied as ultra-thin, spread tow tapes preimpregnated with a very flexible resin. No mylar or other substrate is used. The layups are vacuum-bagged and cured, like any other advanced, high performance composite. And now that technology is saving weight and boosting performance in sporting goods, performance cars and airplanes via North Thin Ply Technology (NTPT). (See Sara Black’s article “Spread tow technology takes off.”)

Related Content

Chantiers de l’Atlantique reveals 66-meter, all-composite SolidSail mast

A technological feat, the large carbon fiber mast prototype targets the Silenseas sailing liner and sailing cargo ships for up to 40% reduction in CO2 emissions.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreAlliance for European Flax-Linen and Hemp reports increasing flax fiber adoption in marine

The natural fiber is increasing traction across several marine applications, including in projects by Greenboats, Northern Light Composites, the Beneteau Group and others.

Read MoreOrbital Composites installs robotic AM system at University of Rhode Island

The 12-axis Orbital S system designed to print continuous fiber-reinforced parts will be used to advance research in composites for underwater unmanned vehicles.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)