Graphene-toughened composites

Are we getting closer to commercialized, and functional, nanotechnology?

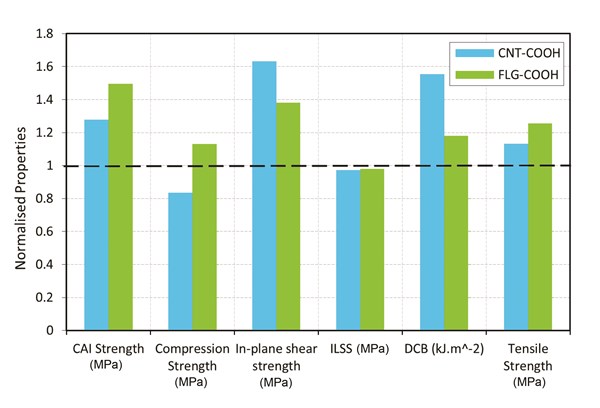

Test results for composites made with carbon nanotube carboxylic acid (CNT-COOH) and few layered graphene carboxylic acid (FLG-COOH) show that adding nanomaterials increases compression strength 13 percent vs. normalized properties and boosts CAI by 50 percent. SOURCE: Cardiff University.

The School of Engineering at Cardiff University and graphene specialist company Haydale Ltd. (Carmarthenshire,U.K.) recently announced new research demonstrating significant improvements in mechanical performance of composites, including impact resistance, using plasma-treated graphene nanoplatelets (GNP).The research was undertaken by the Cardiff School of Engineering with additional funding from the European Community’s Seventh Framework program under the Clean Sky Joint Technology Initiative, aimed at greener aircraft design. The project included the Centro Italiano Richerche Aerospaziale (CIRA), and was managed by an integrated team from CIRA, Cardiff School of Engineering and Haydale.

The research investigated graphene nanoplatelet (GNP) and carbon nanotube (CNT) reinforcement technology. The results observed in this research show a 13 percent increase in compression strength and a 50 percent increase in compression after impact (CAI) performance (see graph above), indicating that fracture mode has been positively influenced, say researchers.

A resin infusion technique was employed to produce composites containing a small percentage of nanomaterials. Significantly, the nanomaterials were surface treated using Haydale’s trademarked low temperature, low energy HDPlas plasma process, which promotes homogenous dispersion and chemical bonding, without waste. The low pressure plasma process can treat both organic mined fine powder and other synthetically-produced nanomaterial powders, producing high quality few-layered graphenes and graphene nanoplatelets. Haydale says the process can functionalize with a range of chemical groups, where the amount of chemicals can be tailored to customer needs. Good dispersion improves the properties and performance of the host resin. The plasma process does not use wet chemistry, neither does it damage the material being processed. Energy requirements are low and the process is reportedly environmentally friendly.

Ray Gibbs, CEO of Haydale, says “These exceptional results underline the potential of Haydale’s tailored, plasma functionalization process in delivering a scalable technology for the production of superior composites. We believe that by working closely with the Cardiff School of Engineering, our combined resources and expertise can significantly accelerate graphene optimization.” Professor Sam Evans from the School of Engineering, Cardiff University, agrees, saying “This research represented a fantastic opportunity for the team at Cardiff to work with graphene materials and technology. Graphene technology has enormous potential for improving the performance of aircraft materials. These initial results suggest that there may be the potential for big weight reductions in aircraft and many other applications, which is very promising.”

Let’s hope that the research comes to fruition. There are many commercialization challenges in moving beyond the lab, and costs of these GNPs has traditionally been very high, as noted by Lux Research senior analyst Ross Kozarsky in the 2013 HPC article, "Graphene: Ready for prime time?". For nanotechnology to benefit composite fabricators, the costs must come down.

One promising nanotechnology product is offered by OCSiAl (U.S. offices in Palo Alto, Calif. and Columbus, Ohio), an exhibitor at the recent CAMX conference and exhibition (Oct. 13-16, Orlando, Fla.). The company can produce single-wall carbon nanotubes (SWCNTs), trademarked Tuball, promoted as a “universal nanomodifier” additive for many types of materials, at a mass industrial scale in a reportedly continuous process. The company offers the Tuball product at the incredibly low price of $2 per gram, according to its Web site. Others are also bringing less expensive products to the market as reported in the September issue of Nanotech Magazine. Perhaps greater adoption of nanotechnology forms for better-performing composites will soon be a reality.

Related Content

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More