ORNL demonstrates 3-D printing with carbon fiber

Oak Ridge National Laboratory can print carbon fiber reinforced parts from 10 cm in size up to 2.4m in both lab and production settings at its Carbon Fiber Technology Facility.

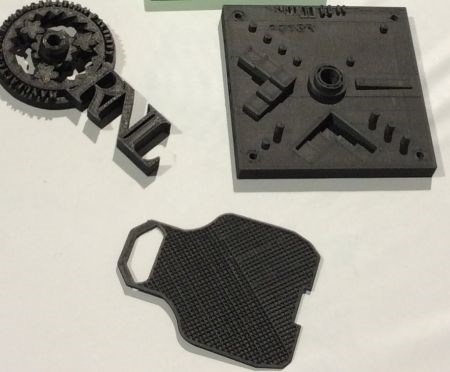

ORNL printed several small (10 cm) parts during its live demonstration

at the JEC Americas show. SOURCE: CompositesWorld

Oak Ridge National Laboratory (ORNL, Knoxville, Tenn.) demonstrated its 3-D printing capability using discontinuous carbon fiber live on the exhibit floor at the recent JEC Americas show (May 13-15, 2014, Atlanta, Ga., USA).

The single head printer uses fused deposition modeling (FDM) with fine carbon filaments, roughly 6 to 7 microns (micrometers) in diameter. (Human hair is approximately 50 micometers in diameter.)

FDM is a common type of 3-D printing in which molten thermoplastic materials are sequentially deposited in a digitally determined pattern to form a part. These parts are typically used only for prototyping because they lack structural properties. ORNL has worked to introduce carbon fiber into polymeric materials for 3-D printing to improve strength and stiffness of printed parts. ORNL can can produce carbon fibers in both laboratory and production settings at its Carbon Fiber Technology Facility (CFTF), which allows it to use alternative precursors, modify fiber properties and apply custom surface treatments and sizings compatible with FDM materials and processes.

Using discontinuous carbon filaments prevents issues with starting and stopping of the print head and allows production of parts with complex geometry. The filaments are combined into a polymeric matrix and the feedstock is prepared for FDM.

ORNL Manufacturing Demonstration Facility feedstock for FDM.

SOURCE: CompositesWorld

ORNL can use a wide variety of polymer matrices including acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and nylon. The print head can also be modified to accommodate higher performance matrices like polyetherimide (PEI) and polyetheretherketone (PEEK). Through work conducted at the U.S. Dept. of Energy's Manufacturing Demonstration Facility, ORNL has demonstrated that incorporating carbon filaments into the FDM process results in parts with 5 to 6 times the stiffness of unreinforced polymer and improves dimensional stability as well.

ORNL printed several small parts (10 cm) at the show (top photo) but also displayed a full-size chair which it printed with a large machine capable of producing objects over 2.4 m in any dimension.

Full-size carbon fiber chair printed by ORNL Manufacturing Demonstration Facility.

SOURCE: Oak Ridge National Laboratory

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

.jpg;maxWidth=300;quality=90)