The end of delamination?

A spin-off from MIT's NECSTlab, N12 Technologies Inc. launches NanoStitch, the world's first vertically aligned CNT product via a continuous industrial process, which bridges adjacent CFRP plies, boosting interlaminar shear and increasing fatigue life by 100%.

N12 Technologies is commercializing NanoStitch, the world's first vertically aligned CNT product via a continuous industrial process, which bridges adjacent CFRP plies, boosting a variety of composite properties. SOURCE: N12 Technologies.

The NECSTlab (pronounced “next lab”) research group, directed by Dr. Brian Wardle in the Dept. of Aeronautics & Astronautics at MIT (Cambridge, MA, US), explores new concepts in engineered materials and structures. One of its achievements over the past decade has been to enhance the performance of advanced aerospace materials and their structures using nanomaterials through the industry supported NECST Consortium.

NECST Consortium members, which also include ANSYS (Canonsburg, PA), focus on improving aerospace structures through strategic use of nano-engineered materials and architectures. SOURCE: MIT NECSTlab.

Commercialization

N12 Technologies Inc. (Cambridge, MA, US) is a nano-engineering company spun out of this effort, which has exclusively licensed MIT’s suite of patented vertical aligned carbon nanotube (VACNT) technologies. Its first two products are NanoStitch, a VACNT film added during layup to reinforce the interlaminar region, and Surface Layer System (SLS), which improves thermal and electrical conductivity, initially proven in deicing and surface curing applications. I recently toured N12 Technologies’ Cambridge facility, and was impressed with what the technology can do and where it is headed.

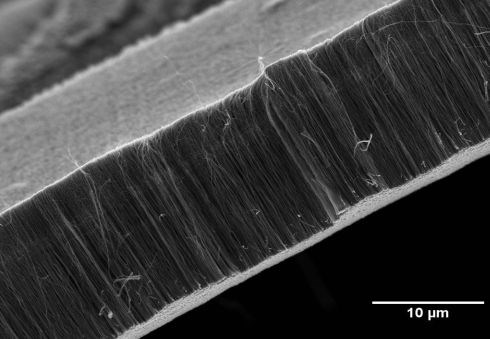

Described in CW’s Nov 2015 feature, “Aerocomposites: The move to multifunctionality,” the VACNT “forests” used in N12’s NanoStitch and SLS products are currently being grown in a furnace in a continuous process. Catalyst “seeds” are deposited onto a thin film substrate, which is then passed through a furnace filled with commercially available industrial gases to generate a reducing hydrocarbon atmosphere. The CNTs grow vertically, their height determined by the process parameters and their density defined during seeding.

Vertically aligned carbon nanotubes (VACNTs) are grown onto a substrate in a continuous process and can be applied to prepreg using normal hand layup as well as automated in-line processes. SOURCE: N12 Technologies.

The NanoStitch VACNT film is tailored to match the gap between prepreg plies, approximately 10-30 microns depending on the fiber/resin system. “This interlaminar region is often where cracks form and propagate in composite laminates,” explains N12 senior scientist Dr. Ryan Williams. “We are mitigating crack formation and propagation by putting trillions of carbon nanotubes in the way.”

N12 Technologies is characterizing these VACNT products, making samples with embedded films — for example, between plies in a 16-ply quasi-isotropic unidirectional carbon fiber/epoxy prepreg laminate — and then testing these to failure, enabling analysis of NanoStitch’s effect on the laminate strength, stiffness and failure mode. The company is also characterizing the material and process, for example, quantifying the VACNT height, carbon content and density, and establishing the statistical quality control measures necessary for qualification and high-volume manufacturing.

Sheets of NanoStitch transferred to prepreg, like those above, are being used in test laminates to characterize the material and its effect on composite strength, stiffness and failure mode. SOURCE: N12 Technologies.

N12’s business plan targets recreational, consumer and industrial sales first while continuing ongoing development work with aerospace customers, targeting commercial-scale supply from a newly renovated, larger facility in 2016 and a capacity of 2 million m2/yr by 2018-19. The company has formed joint development agreements (JDAs) and technical partnerships with global manufacturers of carbon fiber prepregs, adhesives and RTM-compatible resin films. Through these programs, it is developing in-line means for adding NanoStitch into current prepreg products as well as resin films and tapes which can be used with HP-RTM and resin infusion. This resin film work is also being extended to thermoplastic PEEK films and a range of adhesive tapes enhanced with NanoStitch. “The goal,” says N12 CEO Brad Berkson, “is for composites manufacturers to choose from a technically-optimized range of quality products, made by an array of world-class suppliers, delivered through proven supply channels.

Boost in properties

NanoStitch mechanically bridges adjacent carbon fiber plies, at less than 1% volume fraction, or less than 2 g/m2 in additional mass per ply. The baseline interlaminar shear stress (ILSS per ASTM 2234 test method) improvement that N12 Technologies initially saw was 10-12%. As the company has scaled and improved continuous production of NanoStitch, ILSS increases of 30%+ have been demonstrated for a range of fiber and resin composites, for example: composites made from IM7 carbon fiber/ TC350-1 epoxy unidirectional prepreg from TenCate (Morgan Hill, CA) with an ILSS of 84-87 MPa showed a 31-34% improvement to 110 MPa. Data has also been generated for composites made with Hexcel IM7/8552 prepreg and improvement to additional properties have been demonstrated, including the list below. N12 has also demonstrated a 100% increase in fatigue life possible and a 100X improvement in shear fatigue life. Conway, et. al. presented “Fatigue response of carbon fiber epoxy laminates with vertically-aligned carbon nanotube interfacial reinforcement” at SAMPE Baltimore 2015 (May 18-21, Baltimore, MD, US).

- Compression After Impact (CAI)

- Component Fatigue

- Open Hole Compression (OHC)

- Fracture Toughness

- Through Thickness Conductivity

- Tensile

- Through Bolt Bearing

- In Plane Shear – including aged testing

An additional benefit of N12’s VACNT forest materials is they are embedded in polymer, making them safer and more easily handled like other standard composite materials including prepregs and adhesive films. “Our testing of prepregs has shown the films are not damaged by routine handling and layup and the VACNT forests are held together in the matrix,” says Williams.

The end of delamination?

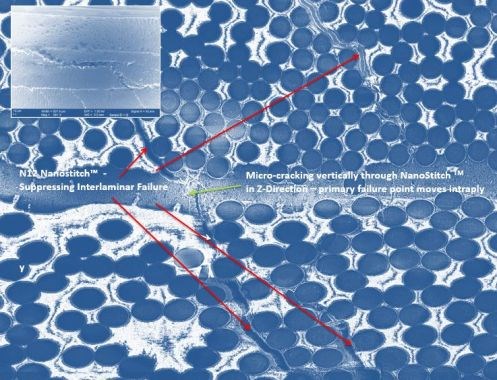

One of the potential applications where NanoStitch has already demonstrated a real improvement is in ply drops, for example where a laminate drops from five plies in the layup to four, etc. “There is a resin pocket where the plies drop,” explains Williams. “By adding local NanoStitch reinforcement at the resin pockets, we not only enabled the composite to fail at a higher load, we actually changed the failure mechanism. The laminate never cracked between plies, but instead the surface fibers broke.” Williams says this was achieved by adding a very small amount of material, less than 1% of the volume of the part. Details were presented by Gouldstone, et. al. at SAMPE Seattle 2014 (Jun 2-5, Seattle, WA, US) via the paper, “Reinforcing Ply Drop Interfaces Using Vertically-Aligned Carbon Nanotube Forests.”

NanoStitch suppresses interlaminar failure, moving the primary failure point into the prepreg plies. SOURCE: N12 Technologies.

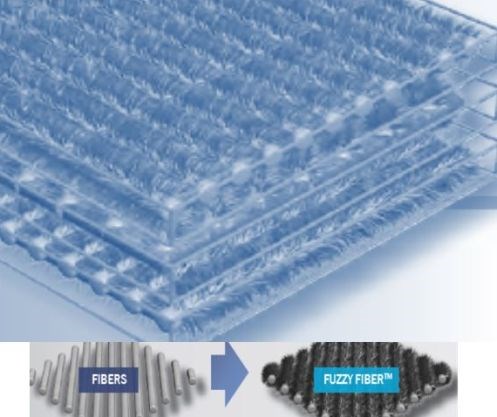

This has led the company to look at some of the other patents in its IP estate, namely those dealing with aligned CNTs grown radially onto the carbon fibers themselves, creating what are termed “fuzzy fibers”. According to Williams, the process to make these fibers with radial A-CNT forests is quite similar to that for NanoStitch, with the fiber being seeded and processed instead of a film. A hybrid technology combining NanoStitch between plies and fuzzy fibers inside each ply, is the next product the company will look at commercializing, in 3-4 years after NanoStitch is well into its planned roll-out. “With NanoStitch’s ability to basically eliminate delamination,” says Berkson, “the next failure mechanism to attack is the cracks that form within the prepreg plies.” By using fuzzy fibers inside the prepreg plies, cracking at the resin-to-fiber interface can be prevented. “So, you might be able to use CNT-augmented fibers to make glass composites perform more like CFRP,” he adds.

Future N12 hybrid technology products will combine NanoStitch between prepreg plies to eliminate delamination, while Fuzzy Fibers within each prepreg ply will prevent cracks within the prepreg plies. SOURCE: N12 Technologies

N12 Surface Layer System

The NanoStitch technology is also being developed as a film with high electrical and thermal conductivity. It can be embedded into typical surfacing film products with uniform resistance that can be tailored to meet specific needs. “This technology has already been tested by partners for a deicing structure for aircraft,” says Williams, noting that the technology could also be used to cure laminates, with the top ply providing heat to cure the plies below without an oven or autoclave.

The team is also looking at using N12 SLS as a thermal layer in tooling to boost the number of cycles possible by increasing the laminate toughness — i.e. its resistance to micro-cracking from thermal cycling and tear out. This resistive layer could also serve to monitor cure of the part at the tool interface. The VACNT film can go up to 400°C or higher, enabling it to be processed along with PEEK.

For more information, details on properties, testing and development, visit N12 Technologies in the 2015 CAMX Exhibit Hall, booth S123. “N12 is also speaking at Carbon Fiber 2015 in Knoxville, TN December 9-10. For more information go to www.carbonfiberevent.com.

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

CFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)