The resurgence of GLARE

Airbus pursues fiber metal laminates for future narrowbody construction, citing cost, weight, repair and lightning strike benefits.

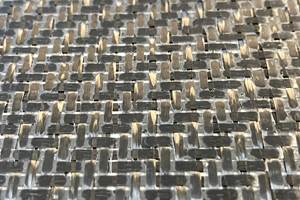

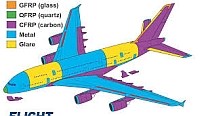

GLARE, made from interlayered thin sheets of aluminum and unidirectional S2-glass prepreg, reportedly cut weight 30% vs. aluminum in 27 fuselage panels on the A380.

SOURCE: Flight Global (left) and AGY (right).

In a 2014 SAMPE Europe presentation, Christian Ruckert, head of Airbus R&T Materials & Process based in Bremen, Germany, showed the familiar graph of increased composites use in commercial aircraft with the upward arrow pointing ever higher as it passed the B787, C-Series and A350. But his commentary? Don’t bet on it.

He cautioned that the cost to develop and implement new composites technologies on upcoming aircraft will have to be much lower than what was seen on the most recent models. He then said that titanium-based additive layer manufacturing (ALM) and Glass Laminate Aluminum Reinforced Epoxy (GLARE) will see growth in future aircraft. More specifically, he noted that though GLARE usage dropped off after the A380, recent changes in automation make it lower cost vs. straight composites.

I’m not sure anyone in the audience took Ruckert seriously. I did, however, and wrote about it (see “SAMPE Europe highlights: Composites face challenges in next commercial airframes”). Now his predictions are bolstered by Premium AEROTEC’s (Augsburg, Germany) recent presentation “New Chance for Fibre-Metal-Laminates as Hybrid Material for Mobility”.

I summarized the presentation at the end of my recent blog “Day One highlights from 2016 CFK Valley Stade Conference”. Side note with regard to Ruckert’s ALM predictions: Premium Aerotec has recently announced serial production of 3D printed titanium parts.

Fokker’s traditional, non-automated production of GLARE fuselage panels included rolling out thin (0.2-0.5 mm) aluminum sheets over layers of unidirectional S-glass-reinforced adhesive film and autoclave cure in shaped molding tools. SOURCE: Fokker.

Tier 1 Suppliers of GLARE

Premium AEROTEC makes 5 out of 27 fiber metal laminate (FML) shells for the A380. They also make the FML butt straps for the A400. They are a Tier 1 supplier with production on every civil and military program for Airbus and also manufacture parts for the Boeing 787. Described as a subsidiary of Airbus, the company’s website claims it was spun off as an independent company in 2009 by combining the EADS Augsburg site with the Airbus facilities in Nordenham and Varel, Germany. The company has >7,000 employees and grossed €1.9 billion in 2014.

Fokker Technologies (Papendrecht, The Netherlands), a division of GKN Aerospace (Redditch, UK) reportedly supplies 22 GLARE fuselage sections for the A380. It cited its role in the original development of the technology — along with TU Delft (Delft University of Technology, Delft, Netherlands) — in its April announcement of its own program with Airbus to automate FML production (see “Fokker, Airbus partnership to focus on glass fiber/metal laminate”). Fokker’s early development is also featured in a short online Prezi slideshow by Devin Cook.

Mentioned by Premium AEROTEC as the third Tier 1 partner in the FML automation development, Stelia Aerospace (Toulouse, France) is a subsidiary of Airbus formed in 2015 by the merger of Sogerma (Mérignac, France) and Aerolia (Toulouse, France), the latter supplying fuselage panels for the A380.

Fokker's production of GLARE panel assemblies did use automated nondestructive inspection for quality assurance. Note the ply build-ups around the door opening. SOURCE: Fokker.

Benefits of FML

According to Fokker’s Innovations webpage, the 27 GLARE panels in the A380 upper fuselage cut weight by 30% compared to aluminum. In its web-published primer on bonded metal and FML structures, Fokker explains that GLARE parts are bonded assemblies, and thus can be made much larger that standard aluminum plate permits — skins spanning ≈30 m2 comprising more than 20 elements, including stiffeners.

In Fokker’s April 2016 news release, Maarten van Mourik, director for large commercial aircraft, says that FML’s better fatigue resistance means inspection intervals are shorter than for aluminum, yet it can be repaired much like metal structures.

He notes FML also beats composites on weight saving in small fuselages because the latter “carry a weight penalty, due to minimum thickness for damage tolerance.” Fokker touts GLARE as having superior bird strike resistance vs. aluminum — hence its use on all of the leading edge surfaces in the A380 tail — but yet requires less intensive nondestructive inspection vs. composites, because impact results in a visible external dent, which is a good indicator of delamination size and shape. Damage reportedly stays inside the aluminum deformation. GLARE is also praised for superior lightning strike performance vs. traditional aerocomposites, already having a conductive metal surface and interior planes without the added weight and expense of adding conductive mesh or foil.

Mourik says FML is best suited for fuselages, bottom wing skins and, as described above, leading edges of wing and horizontal or vertical stabilizers. In addition to the A380 fuselage panels, a 2011 review of FML lists Fokker 27 aircraft lower wing skin panels and the Boeing C-17 cargo door as other applications.

Meanwhile, Christian Ruckert remains heavily invested in FML. He and Tim Axford of Airbus Operations in Bristol, UK presented “Fibre Metal Laminate Lower Wing Cover Structures” at the AEROMAT 2016 conference (May 23-25, Bellevue, WA, US). They explained that high wing loading drives a lot of weight into a typical metal wingbox, motivating Airbus to explore use of FML from selective reinforcement all the way to full wingskins.

Also at AEROMAT, Professors L. B. Vogelesang and R. Benedictus from TU Delft and Prof. Jan Willem Gunnink from GTM Advanced Structures (The Hague, Netherlands) reviewed 35 years of FML research & development and applications, including lessons learned, new concepts and future outlook.

Out of Autoclave FML

Citing FML's benefits in aircraft construction, NASA Langley sought to address GLARE's traditional manufacturing issues of size limitations and expensive, labor-intensive autoclave processing by developing a vacuum assisted resin transfer molding (VARTM) method (see "Fiber Metal Laminates Made by the VARTM Process"). So far, Airbus and its Tier 1s appear to be focusing on smart robotic-based automation as the manufacturing solution vs. eliminating the autoclave.

Related Content

Film adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MorePontacol thermoplastic adhesive films are well-suited for composite preforms

Copolyester- and copolyamide-based adhesive films eliminate the need for sewing threads or binders when stacking laminates while improving the final part’s mechanical properties.

Read MoreResins, additives, adhesives and 3D printing solutions

CAMX 2023: Arkema’s broad portfolio of products for composites fabricators aim to enhance performance, durability and sustainability.

Read MoreHeat-activated foaming core rapidly achieves net-shape 3D parts

CAMX 2024: L&L Products exhibits its InsituCore foaming core structural technology, which can be used to create foam core composites minus machining or presses, as well as the Phaster A K-700, a rapid-cure adhesive.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)