Transparent composites

What does Apple see that might provide opportunity for future composites?

On January 30, 2014, the U.S. Patent & Trademark Office published a patent application from Apple titled "Transparent Fiber Composite."

SOURCE: www.patentlyapple.com

I was intrigued when I ran across Patently Apple’s posting, “Apple Exploring new Transparent Fiber Composite Materials for Future Devices Including Wearable Computers”. The site relates that Apple Inc. (Cupertino, Calif., USA) has been experimenting with composites since 2007, and has now invented a method for manufacturing relatively transparent fiber reinforced plastic structures.

Interestingly, Mo-Sci Corp. (Rolla, Mo., USA) received a 2007 SBIR research funding award for “High-Strength and Optically Transparent Fiber-Reinforced Composites”, which describes “a need for mechanically strong composite materials of high optical quality and transparency equivalent to window glass” and achieving this “by layering a polymer matrix reinforced with glass ribbons (micron-size glass fibers with rectangular cross section) and a tough compliant polyurethane film.” Apparently Mo-Sci had already licensed technology from U.S. Patent 5,665,450 awarded to the University of Missouri and produced research quantities of glass ribbon-reinforced epoxy for high-strength window applications. The patent shows the technology’s foundation of prior art and accompanying issues, which include difficulty in matching the refractive index of materials due to variations with temperature. The Army Research Lab report, “Transparent Composite Utilizing Nonlinear Optical Polymers” specifically noted that “index-matched systems are transparent only over a narrow temperature range.”

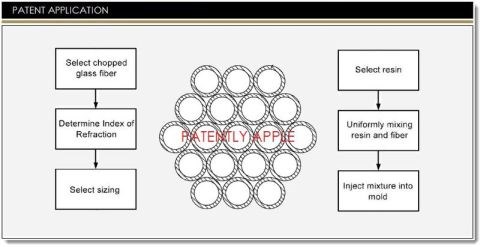

In its application US 20140030522 A1, Apple describes matching the refractive index of the glass fiber, the sizing applied to the fiber and the resin matrix which the fiber reinforces so that the difference between them is less than .005. It also describes forming a transparent fiber-resin composite by injection molding chopped glass fibers ranging in length from 0.25 to 0.50 inch (6 to 13 mm), which can be mixed into the resin prior to injection. This method is said to enable high volume production and even distribution of the fibers in the resin. The patent does NOT disclose how Apple has overcome the RI matching challenges faced by previous developers.

A search on “transparent composites” reveals many different approaches, including bacterial nanofibers, plant nanofibers, chitin particles and polymer nanofibers, and fibers made from polymer ribbons. Transparent composites have also been made using hollow nanofibers electrospun from nylon and polyacrylonitrile (PAN), the common precursor for carbon fiber). The nylon is embedded into an epoxy matrix and the PAN into poly methyl methacrylate (PMMA). Applications claimed include protective armor and aircraft windows.

The high crystallinity of the BioMid fiber makes it more transparent than other natural fibers. SOURCE: June 2013 CT article, “Bio-composites update: Beyond eco-branding”

The RI issue may have been solved through research at Kyoto University (Kyoto, Japan). Led by professor Hiroyuki Yano, transparent nanocomposites were produced by mixing chitin particles (long-chain polymers that form insect, arachnid and crustacean exoskeletons) with acrylic resin and impregnating pulp fibers to form a composite sheet. The resulting composite showed optical transmittance over a wide temperature range.

Pulp fiber sheet before (left) and after impregnation with chitin-modified acrylic resin.

SOURCE: Hiroyuki Yano, Fumiaki Nakatsubo and Kentaro Abe, Kyoto University.

Where do we go from here? Patently Apple asserts that this technology could be applicable in both wearable computers (e.g., the iWatch) as well as integration into other products like sporting goods. In its patent, Apple says clear composites can enable lightweight, strong housings that integrate displays and even camera lenses. That almost implies a multifunctionality that would cut the number of materials and manufacturing steps used in idevice production.

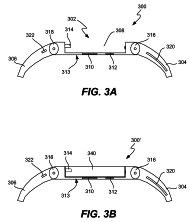

Left: iWatch concept by Todd Hamilton

Right: Images from U.S. Patent US8787006 B2 awarded to Apple,

showing a sensor-packed strap as a dock for various snap in-place modules.

Multifunctionality makes me think of Airbus’ vision for the airliner of 2050, where a futuristic fuselage utilizes topology optimized advanced materials which also provide optical transparency. Though the Airbus images are clearly meant to push boundaries (I’m not convinced being able to see through the fuselage of a commercial airliner is a good idea), what if transparent composites with properties in the range of today’s carbon fiber laminates were possible? And offered selective electrical conductivity and integrated sensors? Solar cells have already been made using transparent graphene electrodes.

Airbus believes future aircraft could be built using a structure that mimics the bones of birds — light, strong and carrying load only where necessary, leaving space for oversized windows and doors, or alternatively, transparent composite laminates. SOURCE: Airbus

Concept cars are also anticipating what might be possible. For example, the GammaConcept claims to use advanced materials as a basis to develop a new visual language, featuring transparent areas to show underlying structure and engine parts. Though this concept uses polycarbonate, perhaps the next generation will opt for transparent composites.

The GammaConcept features large transparent areas, currently achieved with polycarbonate, glued to a glued onto a carbon and Kevlar fiber-reinforced aluminum chassis. SOURCE: Behance.net

Related Content

DITF develops water-spun lignin fibers as PAN precursor alternative

Lignin fibers produced via an aqueous solution and dry spinning process result in homogeneous, smooth-surfaced fibers that are more environmentally friendly and cost-saving.

Read MoreSuper Resin Inc. highlights plant-based epoxy resin, foam core

Eco-friendly resin system using glycol lignin offers an eco-friendly option for CFRP structures and components, and core materials.

Read MoreDuplicor biocomposite cladding aids redevelopment of ABN AMRO office building in Amsterdam

Chosen for low CO2 footprint, RC value >9, fire resistance, light weight and high strength, Duplicor façade structures are key to two-story extension.

Read MoreJEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)