Two visions of 3-D printing in CFRP

Freespace Composites and MarkForged pursue different paths to exploit carbon fiber in 3-D printing.

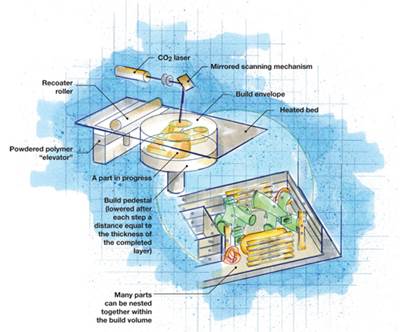

Freespace Composites rendering and Mark One prototype 3-D carbon fiber printers.

Source: Freespace Composites and MarkForged

Both of these systems use carbon fiber in a thermoplastic matrix. Canada-based Freespace Composites is pursuing funding and finishing up software development. MarkForged (Cambridge, Mass.) has announced its Mark One is available for pre-order ($4,999) with shipments reported to start second half of 2014.

Freespace Composites employs a proprietary process that uses a high-strength carbon fiber-reinforced thermoplastic filament, placed optimally and continuously to produce continuous fiber structures in any direction. “Our printer consists of several multi-axis print mechanisms that are essentially 6-axis robot arms," says project principle, Nathan Armstrong. "Another 4-axis robot arm holds the part being printed, allowing the fiber to be placed in any direction, limited only by gravity and the physical possibilities of placement."

The design process starts in a standard structural optimization software package with available working volume and performance parameters as the only inputs. “However,” says Armstrong, “because our system is aimed at structural parts — nonstructural parts can be made with a normal layered printer — we are pushing linking the Freespace system directly to optimization-driven design.” This means optimization results are fed into proprietary “feedback loop” software that iteratively calculates part optimization vs. possible physical fiber placement. “Once this is complete,” explains Armstrong, “the 3-D printing process begins. This eliminates the traditional process of design/engineering/FEA/tooling by connecting optimization software directly to the 3-D printer.”

He describes the rendering above as a small industrial unit with a roughly 1m3 print area and adds, “we're exploring much larger print areas which use the same software but a much larger printer.” Armstrong and team are exploring partnerships for rollout and envision commercialization within five years.

MarkForged unveiled the Mark One — touted as the “World’s first carbon fiber 3-D printer” — at the SolidWorks World 2014 conference (Jan. 26-29, San Diego, Calif., USA). CEO Gregory Mark is an aerospace engineer whose previous company, Aeromotions, designs and builds computer-controlled carbon fiber composite race car wings. His vision was to use 3-D printing hardware to automate composite layup.

The Mark One’s specifications list poly lactic acid (PLA), nylon, continuous carbon and continuous glass filament as print materials and composite filament fabrication (CFF) and fused filament fabrication (FFF) as print techniques. The latter is another name for fused deposition modeling (FDM), while CFF is apparently Greg Mark’s creation. 3-D industry sources say it’s basically an extrusion printer, pushing 1.75 mm/0.07 inch FFF filament and 4 mm/0.2 inch CFF filament materials out through a dual extrusion head. Build volume is 305 by 160 by 160 mm (12 by 6.25 by 6.25 inches, or 486 in3).

Carbon fiber/nylon part in the Mark One 3-D printer. SOURCE: MarkForged

In his SolidWorks World presentation, Greg Mark said it took 20 design iterations to finalize the machining platform, or bed, which uses kinematic couplings (fixtures designed to constrain an object in place) to ensure the bed is within 10 microns of level every time it clicks into place.

The Mark One definitely benefits from slick industrial design and equally slick marketing. With its release going viral in the 3-D community, it will be interesting to see if the Mark One ‘greases’ development of novel composite structures.

Related Content

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreRead Next

The rise of rapid manufacturing

An outgrowth of rapid prototyping, tool-free additive fabrication technologies have the potential to form small, limited-run composite parts directly from CAD data.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More