Ultrasound evaluation of prepreg impregnation levels

The Ultran Group has developed non-contact ultrasound (NCU) that can accurately assess prepreg level of impregnation (LOI) with implications for out-of-autoclave processing, inline quality control and even automated tape laying.

Share

Read Next

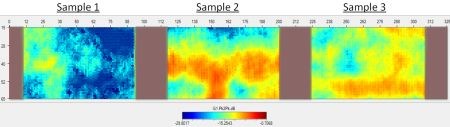

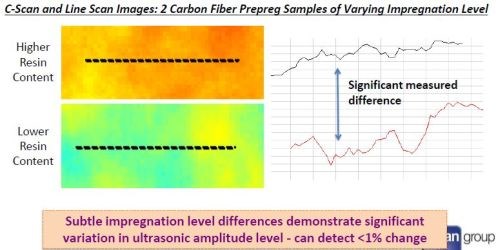

Direct NCU transmission of different single layer CFRP prepregs assessing level of impregnation (LOI). SOURCE: The Ultran Group

Several weeks ago I blogged about 2014 Small Business Innovation Research (SBIR) funding solicitation being short on composites. The Ultran Group (State College, Pa., USA) commented, pointing out that they have a composites-related 2014 SBIR award. Indeed they do, awarded via the U.S. Department of Defense (DOD) and U.S. Air Force titled, “Standard Test Method for Prepreg Resin Impregnation Level.” The goal of the research is to develop standardized test methods for prepreg resin impregnation levels.

My first reaction was, “Don’t they already have a test for this?” and then my eyes kind of glazed over at the words “Standard Test Method”, for which I should be chastised, because the story of what’s going on here is anything but dull. In fact, The Ultran Group has already demonstrated that NCU can detect LOI changes of less than 1 percent. And this technology has the potential for integration into automated tape laying systems, measuring porosity on the fly, real-time.

No trustworthy standard test

According to The Ultran Group CEO Anuj Bhardwaj, “There really is no trustworthy standard method to measure level of impregnation (LOI) in prepreg.” He says the best known method is referred to as the ‘water uptake test’ where prepreg is sandwiched between two layers of coated aluminum and weight is measured before and after immersion in water. The increase in weight equals the amount of water absorbed and is supposed to indicate the level of impregnation or lack thereof. The idea is that if the prepreg reinforcement is fully impregnated with resin, then there is no room for water to be absorbed. But out-of-autoclave (OOA) prepregs are NOT fully impregnated. From my Jan 2011 article “Out-of-autoclave prepregs: Hype or revolution?”:

According to Ridgard, most OOA prepregs for hand layup incorporate dry fiber paths to some degree, which permit air extraction during cure but result in less than 100 percent impregnation.

ACG’s Ridgard explains that in OOA processing, removal of volatiles, which include not only air entrapped during layup but also the moisture (1 to 2 percent) that epoxies absorb when they are exposed to ambient air, involves an “edge-breathing” strategy. The laminate edges must be in contact with the breather and materials must be arranged in a way that maintains air escape paths.

Chris Ridgard, now at Cytec, was one of the first to preach edge breathing for low void content laminates using OOA prepregs. So here is at least one serious issue when you’re testing prepregs for LOI. Hold this thought. I’ll come back to it.

Non-contact Ultrasound (NCU) and inline quality control of composites

The Ultran Group’s web-site features a post titled “Shifting Gears” which gives a good background on their development of NCU. I’ve compiled the highlights:

Ten years ago, NCU was an obscure and nascent technology, unknown to virtually all testing experts. Today, it is quickly growing in adoption as more and more companies are looking for competitive quality control solutions. While ultrasound has been widely used for decades, it has been limited by the need for contact or liquid coupling. The Ultran Group has invested many years of R&D into overcoming these issues and innovating NCU transducer technology. Having delivered its first set of 24/7 in-process testing systems in 2012, the company is now deploying many such systems and is increasingly moving towards providing high-throughput, 100 percent inspection solutions for production quality control.

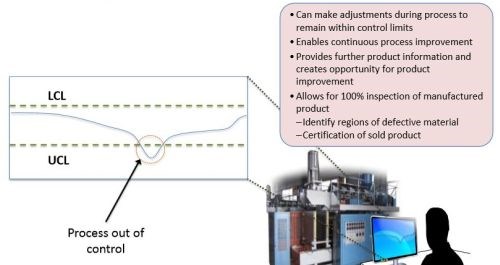

Continuously monitoring the upper and lower control limits (UCL and LCL) of a manufacturing process allows for instant feedback and control, reducing waste and saving money.

SOURCE: The Ultran Group presentation at JEC 2014.

Prepreg manufacturers already using multi-channel NCU systems

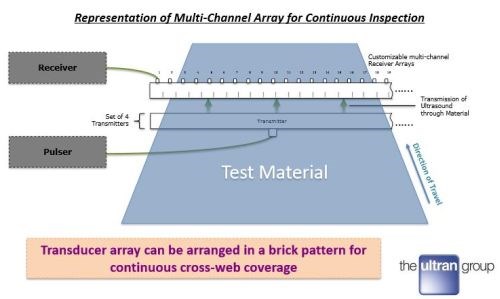

Bhardwaj explains that even though the use of NCU for prepreg LOI measurement is not widely known, “we’ve already sold these systems to leading aerospace-grade prepreg manufacturers for online/inline inspection.” Described as “multi-channel”, these systems use arrays of transducers — 8, 16, 32 or more — with transmitters on one side of the prepreg and receivers on the other (i.e. bottom vs. top) across the entire width of the sheet being manufactured.

A multi-channel NCU array can continuously analyze prepreg web or even cured parts.

SOURCE: The Ultran Group presentation at JEC 2014.

The Ultran Group’s software then creates rolling line scans or C-scans of the material/parts being inspected. As shown in the diagram of UCL vs. LCL, it’s relatively easy to then watch for aberrations and react quickly as they start to appear. In fact, the software can do that on its own, with alarms for when measurements are nearing prescribed limits.

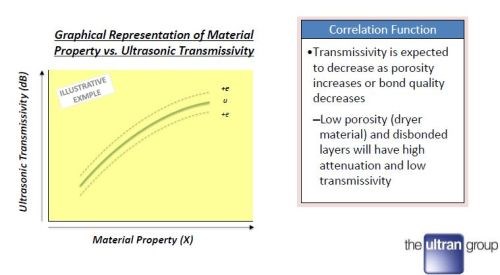

The wetness or porosity of carbon fiber prepreg can be directly correlated to ultrasonic signal amplitude in non-contact analysis. SOURCE: The Ultran Group

“UT is very sensitive to a change in the medium through which the sound passes,” notes Bhardwaj, “in this case, the strength of the signal will decrease with increased porosity in the prepreg.” He explains that the prepreggers using these systems have developed their own correlation between NCU transmittance and prepreg LOI, but this knowledge is obviously proprietary to those companies. “This SBIR gives us the opportunity to build independent correlations from the bottom up and make all of this public to the industry,” says Bhardwaj. Basically, the work is to develop calibrations based on investigating the many different transducer and signal variables and then produce curves correlating the transmission signals with porosity, LOI and other prepreg sheet properties. “We have to filter out the noise that we don’t want to measure and show reliability in measuring LOI for prepregs regardless of fiber weights, resin types, etc.” Then, that understanding will be used to draft an ASTM standard test method.

The relationship between the desired material property and ultrasonic amplitude can be formulated using statistical analysis on experimental results.

SOURCE: The Ultran Group

Aurora Flight Sciences (Manassas, Va., USA) is The Ultran Group’s partner in this SBIR development work and both companies will be giving presentations at the upcoming CAMX show (Oct. 13-16, Orlando, Fla., USA).

Anuj Bhardwaj will be presenting “Application of Advanced Non-Contact Ultrasound for Composite Material Qualification” on Wed., Oct. 15 at 10:00 am in Room W221 B. He will be followed by Konstantine Fetfatsidis from Aurora Flight Sciences at 10:30 am in the same location with “Correlation of Prepreg Resin Impregnation Levels to Resulting Composite Part Porosity using Non Contact Ultrasound.”

Water uptake test and OOA composites

Back to this test method and its issues. When I Google’d this, I found a 2014 Hexcel patent that outlines the procedure, which I’ve pasted below. Note underneath the test procedure ranges of test values the patent authors considered acceptable, yet further down the patent recommends prepreg that most preferably has a water pick up of less than 3 percent. Remember, The Ultran Group has demonstrated NCU sensitivity to prepreg LOI of less than 1 percent.

|

From Patent EP2703141A1: Water pick up values for the uncured prepreg moulding material and tows of the invention may be in the range of from 1 to 90%, 5 to 85%, 10 to 80%, 15 to 75%, 15 to 70%, 15 to 60%, 15 to 50%, 15 to 40%, 15 to 35%, 15 to 30%, 20 to 30%, 25 to 30% and/or combinations of the aforesaid ranges. The preferred prepregs contain a low level of voids between the tows. It is therefore preferred that each prepreg and the prepreg stack has a water pick up value of less than 15 % or less than 9 %, more preferably less than 6 %, most preferably less than 3 %. |

The U.S. Air Force has estimated the accuracy/repeatability of the water pick-up test to be +/-5 percent, but it wants a test with an accuracy of +/-1 percent and specifically mentions OOA materials:

Partial impregnation is a common practice used to manufacture prepreg materials for the defense industry while full impregnation is used for automated tape materials. The products are used on multiple DoD aircraft platforms to benefit part quality through improved processability. Air transport occurs via different mechanism depending on the product form (dry mid-plane of prepreg verses interstitial gap in tow/tape placement). Successful air evacuation is especially vital to new generation, vacuum bag only (atmospheric pressure only) cured systems. Improved processability translates to improved repeatability and generally improved mechanical performance. (Link to full text)

The Hexcel patent also targets OOA processed prepregs. This makes sense. A company well known for developing OOA composites technology once said, “Pressure solves a lot of problems.” Until now, resin impregnation and porosity could vary and the autoclave basically smoothed out most potential issues. But you can see that OOA prepregs start out with areas of no impregnation. So if you’re getting porosity using an OOA prepreg, how can you be sure it’s your processing variables vs. your raw material? It becomes clearer why this test method is important as the aerospace composites industry steps toward wider use of OOA prepregs, especially in primary structure. You can also see the potential for game-changing quality control in automated tape laying of not just thermosets, but also thermoplastics, which also is a path toward OOA processing and one where real-time, on-the-fly measurement of in situ consolidation and laminate porosity could prove very interesting indeed.

P.S. Research funding for the same basic topic was awarded to Nokomis, Inc. (Charleroi, Pa., USA) for a project titled, “Standard Inline Non-Destructive Determination of Prepreg Resin Impregnation Level.” It is described as directly supporting the Joint Strike Fighter (JSF) program by improving quality control of composite material during manufacturing.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)