Walmart uses CFRP to boost efficiency

The new Walmart Advanced Vehicle Experience (WAVE) truck uses carbon fiber to cut 4,000 lb/1,814 kg and includes 53-ft/16.2m long, one-piece CFRP trailer panels.

Wal-Mart Stores, Inc. (Bentonville, Ark., USA), branded as Walmart, revealed its Walmart Advanced Vehicle Experience (WAVE) concept truck at its Sustainability Milestone Meeting last week. Much like the recent BladeGlider and ZEOD RC electric vehicle (EV) racecars, the WAVE’s front end design is not dictated by a block engine. With its hybrid diesel-electric powertrain fitting completely under the cab, the WAVE can take advantage of a more triangular, aerodynamic body shape. Though it obviously cannot achieve the amazingly low aerodynamic drag that enabled the original DeltaWing racecar to use half the fuel of its competitors at Le Mans and run twice the distance on a single set of tires, the WAVE is a bold step toward more fuel-efficient transports. WAVE partner Peterbilt Motors (Denton, Texas, USA) has already demonstrated that a Class 8 truck can average 10 mpg — versus today’s average of 5.5 to 6.5 mpg — via its SuperTruck.

Nissan BladeGlider (left) and ZEOD RC (right) electric race cars

and the DeltaWing racer that pioneered the triangular body at Le Mans (bottom).

SOURCE: www.gizmag.com

The WAVE truck’s batteries and electric motor are coupled with a diesel microturbine by Capstone Turbine Corp. (Chatsworth, Calif., USA). Its C30 (30 kW) and C65 (65 kW) “range extender” turbogenerators — which can also use natural gas, biodiesel or aviation fuel (Avgas) — fire up after EV batteries reach a set stage of discharge, recharging the batteries and extending driving range up to 500 miles, depending on the type and size of vehicle.

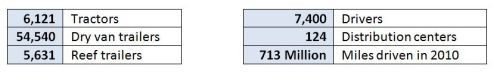

Walmart claims it is the largest private fleet in the U.S.

And then comes the carbon fiber. Walmart says the WAVE’s trailer, built by Great Dane Trailers (Chicago, Ill., USA), “is made almost exclusively with carbon fiber, saving around 4,000 pounds [1814 kg], which can then be used to carry more freight.” It also claims that this is the first time carbon fiber has been used to fabricate a trailer and also the first time 53-ft (16m) continuous composite trailer panels have been made in one piece. (Note: Glass fiber composite trailers were discussed in the February 2003 CT article, “New Lightweight Trailer Delivers Heavy-duty Performance”).

Walmart set a goal in 2005 to double the efficiency of its truck fleet by 2015. According to www.walmartgreenroom.com, the company made significant progress by 2011, increasing efficiency by 69 percent through reduced packaging material and size, improved volume utilization and better route management, enabling delivery of 65 million more cases while driving 28 million fewer miles. During 2010, this eliminated 41 million miles of driving, saving $75 million. The company has added 13,000 skirted trailers (see “Commercial trucking: Streamlining the Big Box” in June 2013 CT) and its efficiency gains equate to avoiding almost 41,000 metric tons of CO2 emissions, the rough equivalent of taking 7,900 cars off the road.

In constant pursuit of its efficiency goal, Walmart has built a variety of prototype tractors including the technologies highlighted below, aiming for an average fuel consumption of 10 mpg or more. While it evaluates its latest WAVE fleet efficiency program prototype, Walmart announced it will buy 2,000 hydrogen-fueled forklift trucks for use in its U.S. and Canadian distribution centers.

Hybrid assist: Tractors using a traditional diesel drivetrain with an electric motor to recover energy normally lost during braking. The hybrid also provides additional torque in high-load situations like climbing hills. Onboard batteries power heating, air conditioning and the electrical system when the engine is off. This first hybrid tractor built by Peterbilt and Eaton Corp. (Cleveland, Ohio, USA) showed promise, but the batteries need improvement in cost, size, weight and capacity in order to achieve an acceptable return on investment (ROI).

Wheel-end hybrid assist: Similar to the hybrid assist, this model built with Freightliner features two wheel-end electric motors on the second axle, placing energy precisely where it is needed and avoids energy loss from the front of the tractor. However, recharge of the hybrid battery has been an issue due to the motor placement.

Full propulsion hybrid: This dual-mode hybrid, built by Meritor (Troy, Mich.), runs completely on its electric motor at speeds up to 48 mph, switching to its diesel engine above that threshold. The next generation is already in development with an enhanced battery system and improved robustness.

Natural gas: For the past three years, Walmart has been testing five liquid natural gas trucks — made by Westport (Vancouver, BC, Canada) in California. It is also testing a Westport/Cummins Alpha 12-liter natural gas engine. Though the company continues to evaluate potential savings and efficiency gains with natural gas, its challenges include lack of fueling infrastructure.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More