AFPT GmbH expects to acquire composite tube manufacturer

Netherlands-based Alformet BV will enable AFPT to expand the use of tubular, fiber-reinforced thermoplastic structures across a wide range of end markets.

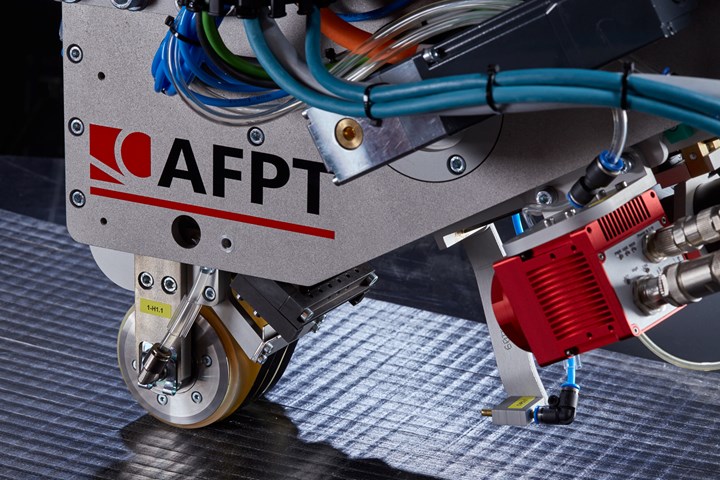

Photo Credit: AFPT GmbH

AFPT GmbH (Dörth, Germany), a global laser-assisted, fiber-reinforced thermoplastic tape (LATW) placement and winding equipment company, has entered exclusive negotiations to acquire composite tube manufacturer Alformet BV (Drunen, Netherlands). AFPT says it combines product ordering software with manufacturing services, empowering a wider range of customers to request and afford continuous fiber-reinforced thermoplastic production.

Alformet BV, founded in 2020, has a production facility in the Netherlands and develops innovative software solutions to support the efficient manufacturing of fiber-reinforced tubes and tubular structures.

AFPT GmbH continuously aims to raise the bar and set new standards in the world of thermoplastic composites.

“We are thrilled to be partnering with Alformet as their vision aligns with our commitment to industrialization, and thus further expanding the use of tubular, fiber-reinforced thermoplastic structures in general industry,” says Coert Kok, managing director for new business development at AFPT.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.