D-JOINTS project helps engineers protect composite aircraft structures from lightning strikes

Design of innovative composite hybrid joints with electromagnetic compatibility project tested and validated two types of joint technologies plus software tool for faster design.

Clean Sky 2’s D-JOINTS (Design of innovative composite hybrid joints with electromagnetic compatibility) project has successfully tested and validated two types of joint technologies developed under the C-JOINTS project to protect aircraft from lightning strikes. The joints ensure that an aircraft’s external panels or structures, when made from composite material, are connected in a way that ensures that if hit by lightning, the electrical charge can be conducted safely between panels along the length of the aircraft, preventing damage or safety concerns.

This was not an issue in the days when aircraft were made of entirely metal construction — the electric charge of a lightning strike could be channeled towards the trailing edges of the aircraft and safely discharged. However, with the increased use of composite materials, managing a lightning strike becomes more complex.

The two technologies successfully developed in the C-JOINTS project included:

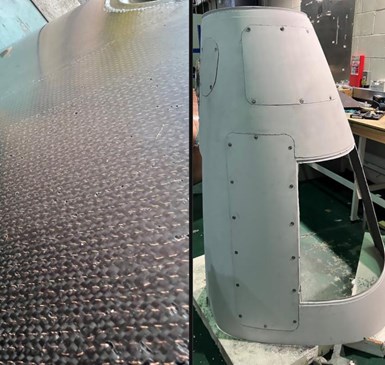

Tufting in demonstrator panel. Photo Credit: Clean Sky 2 D-Joints project, TWI, Cranfield University

- Tufting — an industrial stitching process, applied using robotics, whereby a thin copper thread is sewn through a composite panel to facilitate electrical conductivity.

- Thermal spraying — a process developed at TWI Ltd. (Cambridge, U.K.) whereby metal particles are sprayed onto composites to provide metallic connections that can carry energy between composite-composite panels and between composite-to-metal panels.

The purpose of the D-JOINTS project was to put these technologies to the test, validate their effectiveness and then incorporate the results into a “sizing tool.” This software tool helps engineers design specialized joints that can be embedded in aircraft panels and structures to protect aircraft from lightning strikes.

“This is a user-friendly software tool for engineers,” explains Sonia de la Cierva, project officer at Clean Aviation, “which helps them quickly specify the technical parameters, material characteristics and size of joints that are required when designing aircraft external panels and structures that require embedded protection from lightning strikes. The tufting and thermal spraying technologies were tested and validated for electromagnetic compatibility at demonstrator level on the nose section of the Evektor EV-55 aircraft.”

Moreover, the sizing tool is reported to save time in the design process by making specialized lightning strike protection (LSP) data easily accessible via a convenient user interface. Also, using the tool means that the exact amount of LSP material can be safely used in aircraft structures, thereby saving weight, cutting fuel-burn and curbing emissions.

D-Joint project team with demonstrators. Photo Credit: Clean Sky 2 D-JOINTS project, TWI, Cranfield University

A composite nose section demonstrator was tested in a relevant environment where it was subjected to simulated lightning strike conditions. Results indicated that these new technologies provided effective protection to aerostructures in the event of a strike, as well as protection from the indirect effects of lightning including the electromagnetic fields that lightning generates. These results were confirmed through successful assessment using a technique known as High-Intensity Radiated Field ground tests. Learnings from the project were integrated into the sizing tool.

Environmental advantages

Though the project’s main focus was on protecting composite structures from lightning strikes, the results also have clear environmental benefits. The sizing tool will assist designers in determining the appropriate size and shape of joints needed when designing integrated composite structures with LSP, which will save weight. This, in turn, reduces fuel consumption and emissions. The sizing tool also accelerates the time-to-market due to elimination of time-consuming design review iterations required to develop and produce joints. It does this by enabling the designer to quickly specify the most appropriate type of material combination that can be used for a particular joint.

“A further deliverable, encapsulating the compiled test outcomes and assessment of the environmental benefits is currently in progress,” says de la Cierva. “This will take the form of a summary document that classifies the benefits of the investigated technologies with evaluations of their cost and weight reduction.”

D-JOINTS ran from May 2020 until December 2022 with an EU budget of €468, 000. The project was coordinated by TWI Ltd. and supported by Cranfield University (Cranfield, U.K.) and Brunel University’s Composites Centre (Uxbridge, U.K.). The topic manager was aircraft manufacturer and engineering and manufacturing subcontractor Evektor (Kunovice, Czech Republic).

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreRead Next

After lightning strikes: Repair considerations

When lightning does strike, aircraft LSP system repairs must be done correctly to ensure restoration of protection.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More