ElectraFly, AnalySwift win U.S. Air Force STTR grants

Winning concept proposals include CBAM fabrication of aircraft parts, use of an infusion process for larger parts and development of an integrated computational blade engineering (ICBE) framework.

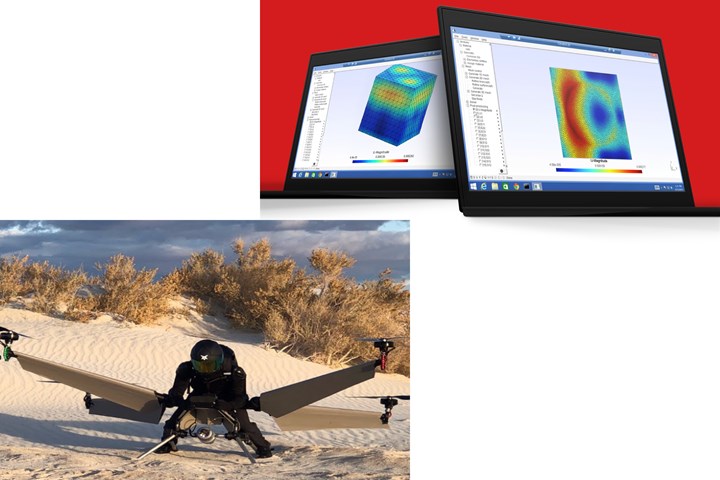

Photo Credit: UAMMI

It was reported on Oct. 28 that two Utah composite materials companies, ElectraFly (Salt Lake City, Utah, U.S.) and AnalySwift (West Jordan, Utah, U.S.) recently won three Small Business Technology Transfer (STTR) grants from the U.S. Air Force (USAF) for the company’s innovative concepts which aim to solve defense-related problems.

The winning proposals were developed with the help of the Utah Advanced Materials and Manufacturing Initiative (UAMMI, Kaysville, Utah, U.S.) and focus on composite material innovations for drones and advanced air mobility (AAM) aircraft that can benefit USAF and also be commercially developed.

ElectraFly, which is developing personal-flight-aircraft (advanced mobility aircraft; see “UAMMI, ElectraFly to make 3D-printed UAM aircraft parts”), submitted two winning proposals. The first is the fabrication of aircraft parts using a Carbon-Based Additive Manufacturing (CBAM) 3D printer provided by its partner Impossible Objects (Northbrook, Ill. U.S.). The parts will then reportedly be tested by Weber State University’s composites lab.

ElectraFly’s second proposal is to use an infusion process to create carbon fiber aircraft parts that are too large for the CBAM 3D printer. These parts will be created with project partner Hexcel (Stamford, Conn., U.S.) and tested at Brigham Young University’s (BYU) composites lab.

According to UAMMI, the third winning proposal was submitted by AnalySwift, a multi-physics modeling company with technology that is said to reduce engineering time and provides virtual testing of composite material structures, such as rotor blades, earlier in the design process (see “AnalySwift launches VABS software on Altair Partner Alliance platform”). The company’s proposal is to develop an integrated computational blade engineering (ICBE) framework for rapid insertion of high-performance composite rotor blades into ElectraFly’s aircraft. The framework will lead to prototyped parts developed by project partner Hexcel and then tested by the Weber State University composites lab.

“We congratulate these companies on their proposals and grant wins,” says Dr. Tulinda Larsen, executive director, UAMMI. “These wins position Utah as a leader in composites research for advanced mobility aircraft, which is the fastest growing market in aviation.”

Each winning grant will be awarded a maximum of $150K in this first of a three-phase program, says UAMMI. The objective of Phase 1 is to determine scientific, technical and commercial merit as well as feasibility of the innovations. Phase 1 projects are to be completed over the next six months with the possibility of follow-on funding for Phase 2 and 3 up to an additional $750K.

According to UAMMI, the grant program is a result of a 2014 review of the United States’ national defense strategy, in which it was determined that the U.S.’ military advantage over its adversaries and peer competitors was steadily eroding and that innovation would be a key tactic to correcting this. Accordingly, under the 2017 National Defense Authorization Act (NDAA) Congress authorized the Defense Commercial Solutions Opening (CSO) program allowing defense contracting officers to acquire innovative commercial items, technologies, or services which could close capability gaps.

The objective of the program is to provide potential technological advancements to the Department of Defense, incentivize small business commercialization of cutting-edge research, strengthen small businesses’ role in meeting DoD research and development needs and fortify the United States’ industrial base.

Related Content

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More