Ingersoll showcases 3D printed winglet layup tool at IMTS

The part was printed with large 3D printing technology developed by Ingersoll Machine Tools and Oak Ridge National Laboratory.

Ingersoll Machine Tools Inc. (Rockford, IL, US) showcased at this week’s International Manufacturing Technology Show (IMTS, Chicago, IL, US) Master Print, the company’s new large-format 3D printing technology with automatic attachment change to 5-axis CNC for aerospace-grade milling. The technology was developed in collaboration with Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US).

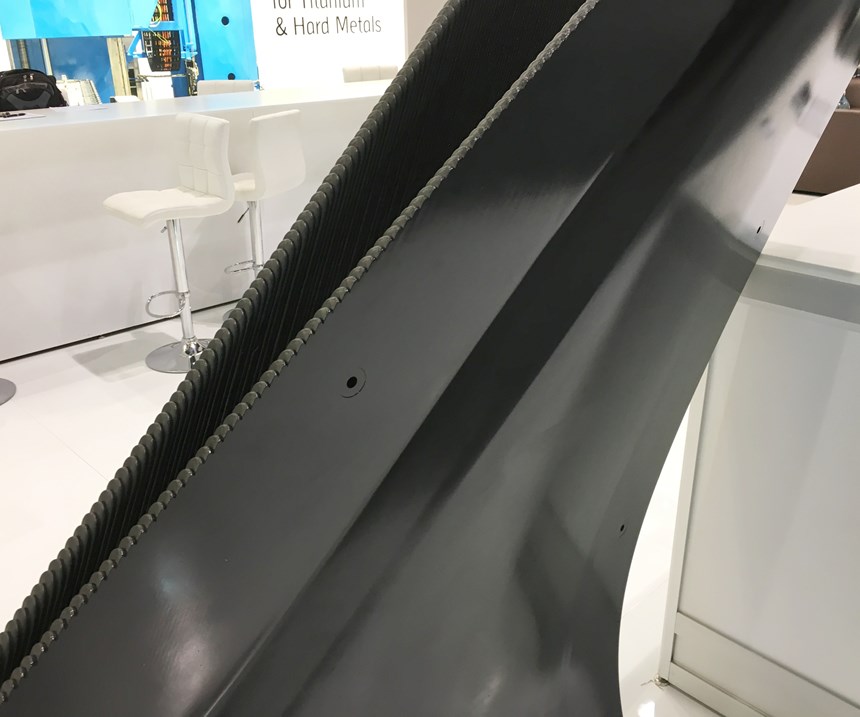

On display is the layup tool for a winglet shown in two stages. One is the just-printed tool. Second is the finished tool with sealant coating, ready to be used.

The part, says Ingersoll, weighs 430 lb/195kg and was printed in 6.5 hours. It was machined in 4.3 hours using the machine’s 5-axis technology. The material is ABS with 20% chopped carbon fiber reinforcement.

Related Content

-

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

.png;width=70;height=70;mode=crop)