JEC World 2016 exhibition and product previews

JEC World 2016 will be held in Paris March 8-10. These are some of the products that will be found at the show.

- Wind/Energy

- Cutting/Kitting

- Sustainability

- Automotive

- Pultrusion

- Carbon Fibers

- Out of Autoclave

- Molds/Tools

- Machining/Drilling

- Materials

- Glass Fibers

- Fabrics/Preforms

- Pressure Vessels

- Adhesives

- ATL/AFP

- Weaving

- Consumer

- Processes

- Epoxies

- Resins

- Thermoplastics

- Aerospace

- Reinforcements

- Design & Tooling

- Marine

- Injection/Overmolding

- Autoclave

- Compression Molding

- Ketones

- Braiding

- Prepregs

- RTM

- Curing

- Infusion

If you're headed to Paris for the JEC World 2016 trade show March 8-10, below is a sampling of new products that you can expect to find at the event.

- Bond-Laminates (Cologne, Germany) is exhibiting new applications for its Tepex range of continuous fiber-reinforced thermoplastic composites. In particular, the company is emphasizing hybrid molding, which combines forming of semi-finished products with injection molding. In hybrid molding, semi-finished composites are both formed and overmolded in an automated one-shot process in the injection mold, thus shortening the production process. The investment costs are also cut by eliminating the forming tool. The result is precision 3D components in highly reproducible quality that do not require reworking and directly integrate functions such as fixings and guides. Cycle times, says Bond-Laminates, are 60 seconds and less. At its Brilon site, Bond-Laminates has installed a demonstration cell for fully automated processing of Tepex using hybrid molding. Bond-Laminates also says it is able to simulate all hybrid molding process steps, whether these concern the draping of the semi-finished composite or mold filling in overmolding the formed insert. Bond-Laminates is showcasing highly integrated, crash-resistant seating shells from a German sports car and a ski binding as examples of series-produced structural components using hybrid molding.

-

Cannon (Peschiera Borromeo, Italy) is offering manufacturing lines for the production of thermosetting or thermoplastic composite parts with bespoke solutions for the automotive, aerospace and transportation markets. They include: Fully automatic glass and carbon fiber preformers with cycle times suitable for the automotive industry; chemical dispensing units and dedicated mixing heads for epoxy and polyurethane resins, using classic injection methods or innovative liquid lay down or spray lay down technologies with multi-component formulations; a new generation of presses suitable for different technologies (HP-RTM, gap injection, compression molding, etc.) and different reinforcements (carbon and glass fibers, nonwoven PP, etc.), featuring an innovative parallelism control system; the CRESIM (Carbon Recycling by Epoxy Special IMpregnation) method for the manufacture of CFRP parts using recycled carbon fibers; handling and heating systems, safeties and electronic process controls; low-pressure DX machines that dispense poxy resin for the infusion of liquid formulations in large wind blades; a degassing unit designed to remove air from resins and avoid the formation of bubbles in cast parts.

-

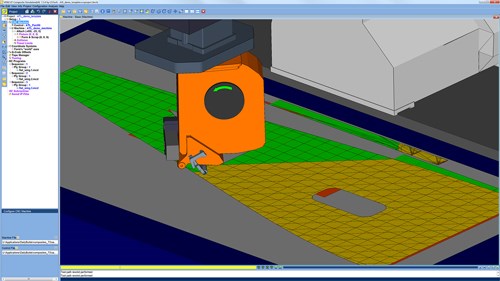

CGTech (Irvine, CA, US; Hove, UK) will demonstrate VERICUT Composite Paths for Engineering (VCPe), VERICUT Composite Programming (VCP) & VERICUT Composite Simulation (VCS). VERICUT is CNC machine simulation, verification and optimisation software that enables users to eliminate the process of manually proving-out NC programs. VERICUT simulates all types of CNC machining, including drilling and trimming of composite parts, waterjet, riveting, robotics, mill/turn and parallel kinematics. VERICUT runs standalone, but can also be integrated with leading CAD/CAM/PLM systems, including Dassault Systemes CATIA, Siemens PLM NX CAM, Delcam PowerMill, Vero EdgeCAM, Open Mind hyperMILL, DP Esprit and Missler TopSolidCAM. Visitors will see first-hand the necessary steps needed to get from a CAD-designed composite part to CNC programs that drive an automated fiber placement (AFP) or automated tape laying (ATL) machine. There will be information on new projects that highlight the implementation and use of machine independent off-line NC programming software for AFP and ATL machines. Current customer projects to be highlighted include extensive use of robots, lasers, probing, and ultrasonic knifes on machines from leading AFP and ATL manufacturers including Electroimpact and MTorres. CGTech will also be featured on the STELLAR project stand in Hall 6, S50. Stellar is a European Commission funded project and the concept is to develop the design methodologies, manufacturing processes, equipment and control systems needed for localized placement of different fiber-reinforced thermoplastic composite tapes onto a range of substrates, creating locally reinforced components that are fully weight-optimised.

-

Chomarat (Le Cheylard, France) is unveiling its new glass fiber reinforcement ROVICUT, which stretches to hug the curves of pipes and conduits that need to be rehabilitated, without sacrificing mechanical performance. The company will also present a new sports and leisure application for its carbon C-PLY line. Chomarat developed ROVICUT in collaboration with Reline Europe, a leading manufacturer of sleeves for in-situ repair of pipes. ROVICUT's sleeve thickness is optimized to make it more lightweight, thus making it easier to handle and install, with faster UV cure. ROVICUT was designed specifically for Reline’s new Alphaliner 1800 line dedicated to large-diameter pipes. Because it is stretchable, ROVICUT takes the exact shape of the worn pipes, increasing the mechanical performance without adding too much thickness to the pipe interior. In sports and leisure, Chomarat says Dynastar's new Mythic 87 line of skis uses Chomarat’s C-PLY multiaxial carbon reinforcements. These backcountry skis were first developed for competitive skiing, but are now available for all skiers. “Thanks to the use of C-PLY, we lowered the weight of the skis by more than 25%, making it more comfortable for skiers and providing higher downhill performance. The combination of Dynastar know-how and the high-tech nature of C-PLY makes the ski the lightest one we’ve ever produced!” explains Dynastar product manager Franz Marsan.

-

Continental Structural Plastics (CSP, Auburn Hills, MI, US) has received the JEC World 2016 Innovation Award in the Automotive Exterior Parts category for its multi-material decklid concept. This decklid, featuring a TCA Ultra Lite outer and a carbon fiber resin transfer molded (RTM) inner, weighs just 12.11 lb/5.5 kg, a 13% weight savings over a similar decklid made from aluminum. The winning decklid concept was collaborated by the CSP R&D teams in Auburn Hills, and Pouance, France, with support from partners at Owens Corning, Compose Tooling Expert, Altair Engineering, PPE, Hexion and Brandolph. It was developed as part of a study to compare the weight of decklids made from steel or aluminum versus a multi-material approach. Also key was reducing the cycle time associated with the use of carbon fiber.

-

Dow Chemical (Midland, MI, US), in a stand shared with DowAksa (Marietta, GA, US; Istanbul, Turkey) and Dow Automotive Systems (Auburn Hills, MI, US), will present its latest high-performance polyurethane and epoxy composite systems for infrastructure, construction, automotive, wind energy and other industries. Special focus will be on composite applications and epoxy systems for tanks that store compressed natural gas (CNG) and liquefied petroleum gas (LPG). Also featured will be BETAMATE and BETAFORCE structural adhesives, and VORAFORCE epoxy and polyurethane composite systems offer ultra fast curing. VORAFORCE products offer low-VOC emissions and are available for HP-RTM, filament winding, infusion, LFI, pultrusion, hand layup, reinforced RIM, spray preg and structural RIM processes.

-

ELG Carbon Fibre Ltd. (Coseley, West Midlands, UK) is introducing its Carbiso line of recycled carbon fiber products that reportedly offer a cost-effective solution to traditional composites in high-volume applications. From a dedicated recovery plant in the West Midlands, ELG Carbon Fibre reclaims carbon fiber from manufacturing and end-of-life waste. This is then converted into products for the composites and compounding industry. ELG Carbon Fibre will focus predominately on its range of Carbiso M and Carbiso TM isotropic mats. These easy to handle, drapeable mats are compatible with most thermoset and thermoplastic polymers and are said to deliver excellent mechanical properties. Carbiso M mats are produced from 100% recycled carbon fiber and can be processed by conventional composite techniques to manufacture structural and semi structural parts. Carbiso TM products are hybrid mats produced from recycled fibers and comingled with thermoplastic matrices for press molding applications.

-

Injection molding machinery specialist ENGEL (Schwertberg, Austria) is featuring its v-duo series injection molding machine, robots and heating systems for the fabrication fiber-reinforced composites. ENGEL is currently commissioning a v-duo 1700 17,000-kN machine for operation at its Center for Lightweight Composite Technologies. The new production cell with injection unit, integrated ENGEL easix multi-axis robot and multi-component high-pressure metering system for reactive processing technology is equipped for composites fabrication. A new IR oven is also available for development and customer test projects.

-

Formax (Leicester, UK), the manufacturer of carbon fiber and speciality composite reinforcements, will showcase its ability to develop innovative solutions for challenging composite applications through a series of one-to-one consultations with its engineering team. Hexcel acquired Formax in January 2016 and the company name will soon be changing to Hexcel Reinforcements UK Ltd. Formax invites all JEC visitors with a reinforcement challenge to stand F39 to discuss their problem with the team of technical experts who will take a fresh look at the issue and offer advice on potential solutions. NCF (non-crimp fabric) Reinforcement Clinics will be offered throughout the show. Customers can either walk on to the stand or book a session in advance by emailing info@formax.co.uk.

-

Granta Design (Cambridge, UK) will demonstrate the new Composites QED data module, which provides authoritative test data for composite materials. When combined with updated materials information management software, it eases composite qualification and equivalency studies. Granta will also speak in the scientific program, discussing a collaborative project in which the company’s tools support composite simulation. Granta software helps engineering organizations to be more efficient in their development and application of composite materials, to better understand material behavior and properties in order to optimize performance, and to support a rigorous composite qualification process. Through a long-standing collaboration with the US National Center for Advanced Materials Performance (NCAMP), Granta already provides customer organizations with digital access to NCAMP’s composite design data, material pedigree data, test results and reports. Now, the new Composites QED data module adds more than 7,500 raw data curves from NCAMP testing, creating an outstanding resource against which to compare in-house test results. Granta also will show the recently released GRANTA MI Version 9, which enables more information management workflows, enhances support for simulation and offers fast and reliable performance.

-

Henkel (Düsseldorf, Germany; Rocky Hill, CT, US) is exhibiting a fiber-reinforced composite leaf spring based on its polyurethane matrix resin Loctite MAX 2 being used in the chassis of the new Volvo XC90, a premium crossover SUV of which the rear axle concept is to serve as a platform for other model series, such as the S90 and the V90. Benteler-SGL, a manufacturer of resin transfer molded (RTM) composite components for automotive applications, is aiming to produce several hundred thousand leaf springs per year. Because of its low viscosity, the polyurethane matrix resin Loctite MAX 2 from Henkel rapidly fills the mold and impregnates the fiber material, reportedly resulting in short injection times. In addition, Henkel will present a holistic lightweight door concept of the Roding R1. The door is manufactured using Henkel’s assembly adhesive solutions and Loctite MAX 3 resin, demonstrating the flow characteristics of that resin family on very complex geometrical shapes.

-

Huntsman Advanced Materials (Basel, Switzerland) will be recognized with a JEC World 2016 Innovation Award, won in partnership with Compose SA, IndAC AG and ThermoFLUX for an entry under the title, “Structural Epoxy parts with autoclave quality in less than 1 minute.” The process innovation involved is Dynamic Fluid Compression Molding (DFCM) which reportedly delivers consistent quality using fast-cure ARALDITE epoxy solutions and characterized by high-fiber content and void-free parts. Huntsman will also emphasize a joint enterprise with Acciona Infrastructures in Spain, along with Aimplas, Dow, SAERTEX, Owens Corning and Autoridad Portuaria de Valencia to design and construct the first ever all-composite lighthouse. For the lighthouse it was necessary to develop a low-exothermic, low-viscosity, epoxy-based infusion and RTM resin with long pot life, and also a suitable epoxy-based structural adhesive which was thixotropic and easy to apply on vertical surfaces.

-

Innegra Technologies (Greenville, SC, US) will feature Innegra S fiber and Innegra H fibers. In addition, many brand products will be on display, all reinforced with Innegra. The products include a bicycle frame built by Berk Composites, a WIME snowboard, custom-designed skis by Jared French, North American Rescue Pegasus Rope, a Bauer hockey goalie mask and Bauer hockey stick. Innegra will also be featured in the JEC World showcase in the Sports Planet and the Auto Planet.

-

Johns Manville (JM, Denver, CO, US) is introducing three new glass rovings: MultiStar 566 for panel and fabrics reinforcements; StarRov 090 for reinforcement of composites profiles; and StarRov 089 for reinforcement of styrene-free resins. MultiStar 566 offers good feeding and chopping with good translucency for panel applications and flat homogeneous mat layout for fabric processing with fast resin impregnation. StarRov 090 is multi-compatible with epoxy, unsaturated polyester and vinylester resins with good wet-out performances. StarRov 089 offers good interlaminar shear strength (ILSS) and improved modulus performance.

-

Textile machinery manufacturer KARL MAYER (Obertshausen, Germany) is featuring its biaxial and multiaxial warp knitting machines, as well as fiber-spreading technology. Featured on the KARL MAYER stand will be a kite board with a reinforcement produced from a multiaxial layer fabric manufactured on one of its machines. It consists of two hybrid laminates that cover a poplar wood core on their upper and lower sides. The composites in the top and bottom structures combine a carbon multiaxial layer fabric ±45° produced on a MAX 5 machine with a UD glass fiber material in 0° direction as reinforced tension/compression chord. Epoxy resin was used as matrix.

-

L&L Products (Romeo, MI, US) is featuring an adhesive film that it developed for BMW for use in its new 7-Series car, which combines carbon fiber-reinforced composites, aluminium and steel. The bonding of dissimilar materials in car bodies requires structural strength with adequate elongation to account for the differences in thermal expansion of the materials. In addition, it is essential to protect against galvanic corrosion that could be caused by the use of different materials. At the same time this problem had to be solved in an automotive environment of volume, repeatability, prevailing plant conditions (such as oily metal surfaces) and process targets (curing time: 2 minutes at 170°C).

-

LaminaHeat (Leixlip, Ireland; Greenville, SC, US) is introducing a new addition to its line of thin, flexible heating materials called PowerFabric Plus. Made from lightweight and homogeneous carbon fiber with copper contact strips, the PowerFabric Plus now sandwiches this heating technology between woven fabrics for significantly improved flexibility and broader application potential. Using a standard fiber glass mat on either side enables the new PowerFabric Plus heating technology to not only add heat where it is needed, but also adds structural reinforcement. The current is applied to the copper strips of the PowerFabric Plus to generate localized heat across the fiber sheet at temperatures up to 300°C. PowerFabric Plus can generate up to 16 kW/m2. PowerFabric Plus can employ various woven fabrics and finishing options.

-

Magnum Venus Products (Kent, WA, US) is offering live demonstrations of the latest in closed molding processes, materials and technology two times daily. The company will also offer ongoing demonstrations of multiaxis filament winding technology from the Advanced Equipment Group of MVP. The closed molding demonstrations will be held at 11:00 a.m. and 3:00 p.m. and will feature the injection/infusion of a skateboard from start to finish using the MicroPro System, an epoxy resin and heated membrane and mold. MVP will also highlight its new Patriot 55-gallon, low-flow 10:1 adhesives system.

-

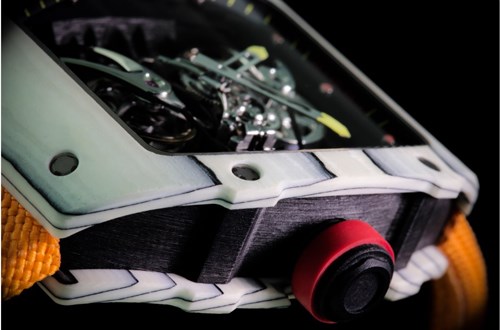

North Thin Ply Technology (NTPT, Penthalaz, Switzerland) has won a JEC World 2016 Innovation Award for its TPT Quartz thin ply prepreg, which was engineered to enable the manufacture of intricately shaped watch cases for Swiss brand Richard Mille. This 52-g/m2 material made its debut in the RM 27-02 Rafael Nadal watch. NTPT developed the prepreg in close collaboration with Saint-Gobain Quartz, which supplied its Quartzel fused quartz fiber reinforcement for this project; Reichhold, which developed an ADVALITE hot melt, monomer-free vinyl hybrid resin for the matrix; and Richard Mille, which led the design and validation work for this highly demanding end use. The project team had to demonstrate that the material was non-allergenic, would not yellow in sunlight (UV) and was resistant to a range of chemicals that the watch could encounter during its lifetime. Using its proprietary spread-tow technology, NTPT manufactured unidirectional (UD) quartz fiber prepreg tapes 300 mm wide with a fiber areal weight of 52 g/m2. The tapes were then transformed into 2D prepreg preforms using NTPT’s automated tape laying (ATL) equipment. The preform is cured to produce a densified composite block, which is machined into the watch components by Richard Mille. The use of thin ply prepreg enables machining into extremely complex shapes without delamination, which ensures that the watch case is watertight.

-

R-Tech Materials (Port Talbot, UK) is introducing its testing and consultancy services to the composites sector. Building on its proven track record as a UKAS accredited laboratory in the metals sector, R-TECH has now developed its capabilities into the testing of polymer and composite materials. R-TECH already has experience in the accredited third party testing of resin and reinforcement materials for use in the marine industry, and is the laboratory partner for Lloyd’s Register EMEA, providing testing services in the field of non-metallic materials, and collaborating on common research themes. Building on its experience in the marine industry, R-TECH has increased its range of testing to include mechanical testing (static, impact, fatigue and creep), microscopy (optical, digital and SEM), chemical analysis and thermal characterization. Testing can be performed on GFRP, CFRP, core materials, sandwich panels, adhesives and structural elements. All tests can be done under controlled temperature and humidity.

-

RocTool (Le Bourget du Lac, France) will present live demonstrations of its new Light Induction Tooling (LIT) out-of-autoclave (OOA) technology, which enables the production of very large parts, but does not require a compression press machine or a large forming press. RocTool says LIT addresses OEM challenges to make cost-effective composite parts with quick cycle times. A light tooling structure integrates RocTool induction heat technology and is connected to RocTool Performance Cooling units. With this new process, RocTool reduces the thickness of the tools and shortens the heating and cooling times to less than 3 minutes in many cases. The LIT offers accurate control over heat ramps, from fast heating to defined heat rates for aerospace-certified resin systems that require an overall longer cycle.

-

Scott Bader (Wollaston, UK) will promote an expanded Crystic Ecogel range with a new ultralow styrene Iso/NPG marine gelcoat, marine-approved gelcoat additions to its GelTint volumetric gel-tinting service, Crestabond PP-04 1:1 adhesive with a working time of 4 minutes, and a sub-3-minute curing Crestabond M1-02 primerless structural adhesive grade, which has been added to the range for high-volume assembly of metal, plastic and composite components. Scott Bader also will have on its stand the prototype for a new British sports car. This new two-seater convertible has a rigid, lightweight carbon fiber (CFRP) composite passenger cell frame fabricated by Axon Automotive (a subsidiary of Far-UK Ltd.), using its Axontex structural beam technology, which specifies Scott Bader’s Crestapol 1250LV as the high-performance infusion resin. Crestabond M1-20 primer-less methacrylate structural adhesive is also extensively used by Axon to bond the CFRP frame sections together. According to Axon Automotive, the passenger cell prototype frame design is 43% stiffer and 15% lighter (by mass) than an equivalent lightweight steel frame.

-

Scott and Fyfe (Fife, Scotland, UK) is promoting its next generation of Polymat FR, an all-glass core mat for high-performance, fire-retardant applications. It offers improved resin flow characteristics, high conformability and the ability to meet the highest level of fire performance, such as EN45545-2, making it suitable for the rail industry. In addition, Scott and Fyfe will showcase a full range of glass reinforcements including chopped strand mat (CSM), woven roving (WR), multiaxial non crimp fabrics (NCF), continuous filament mat (CFM) and single- and multi-end roving.

-

SGL Group (Wiesbaden, Germany) is showcasing the Carbon Core body of the new BMW 7-Series for the first time. Carbon fiber braids of SGL Group are being used as standard in combination with aluminum in the roof frame structure of this model series. The braids are produced in a fully automated process and then supplied directly to the BMW Group as preforms for the component production. SGL Group also supplies carbon fibers, carbon fiber-based fabrics and nonwovens, which are used according to the specific component requirements as standard in various parts of the body of the 7-Series such as the C- and B-pillar pillar, rear panel, door sills, transmission tunnel, and roof rails. SGL Group is involved in this project at various stages of the value chain. Carbon fibers are produced at Moses Lake, WA, US. Subsequent processing of the fibers is carried out specially targeted within SGL Group’s production network. In addition, SGL Group will introduce new SIGRAPREG towpregs based on 50k continuous carbon fiber tow. They can be combined with new rapid-curing prepreg resin systems, which are currently being developed to meet the requirements of future large-scale production in the automotive industry. These snap cure epoxy resin systems combine rapid curing times (< 3 minutes at 150°C) with good storage stability. The preimpregnated semi-finished products also have optimized tack for automated processing. Also featured by SGL Group is a range of fiber-reinforced thermoplastics. These include tapes, sheets and long fiber thermoplastics, which permit very fast cycles, easy weldability, and good recyclability.

-

Sicomin (Marseille, France) is presenting GreenPoxy, its range of bio-based epoxy resins with a bio-based carbon content ranging from 28% to 51%, the highest on the market tested in accordance with ASTM D6866. Sicomin offers bio systems that can be used for hand laminating, infusion, pultrusion, filament winding and HP-RTM. Sicomin will exhibit a bio-based surfboard, snowboard and wakeboard, produced in collaboration with a number of leading OEMs. Another key launch at the show will be SR 1125, an advanced self-extinguishing fire retardant epoxy that can be used for infusion processes at room temperature. SR 1125 reportedly features a low viscosity that ensures a steady, predictable and consistent resin flow.

-

Stellar (Chesterfield, UK) will showcase its automated fiber placement (AFP) technologies that offer high-speed placement of fiber-reinforced thermoplastic tapes in selected locations in a composite structure. To demonstrate the new technologies, work has focused on selectively reinforcing existing components to create hybrid composite structures with localized strength where required. The process and prototype parts will be displayed through a video showing the process concepts, test pieces demonstrating the capability, prototype parts and a demonstrator showing how the tapes are laid. The project is led by NetComposites and includes HBW Gubesch, esi, AFPT, Toyota, Fraunhofer IPT, Kunststoff Technik Leoben, and CGTech.

-

Technical Fibre Products (TFP, Burneside, UK; Schenectady, NY, US) will exhibit a new novel Tecnofire fire-protection material, the first of its kind that can be activated on demand, without heat. The intumescent mat has been designed for use in a remotely activated fire protection system and, due to the presence of the conductive fibres, has the added benefit of acting as an EMI shield. Also on display will be TFP’s new, extended range of high-performance veils made from thermoplastic fibres, including polyphenylene sulphide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK), polyamide and polyimide. These very lightweight materials are designed for use in carbon fiber-reinforced plastics (CFRP) as enhancing interleaves and reportedly can improve mode-I and mode-II fracture toughness by up to 160% and 430% respectively. A further new development for TFP is the company’s certification to the AS 9100 (BS EN 9100) global aerospace quality standard.

-

Victrex Plc (Thornton Cleveleys, UK) is introducing VICTREX AE250 composites, a PAEK-based product family of unidirectional tapes (UDT) and laminate panels. Specifically designed for the aerospace industry, VICTREX AE250 composites are designed for the molding of brackets, clamps, clips and housings used throughout aircraft in primary and secondary structures, from the cabin — including seats — to the engines and fuel tank. The material/process combination is a hybrid injection molding system in whcih VICTREX AE250 continuous fiber sheets are overmolded with short fiber-reinforced VICTREX PEEK polymers. This allows engineers to combine the mechanical properties of the composites with the design flexibility and fast production times of the injection molding process. It is not necessary to pre-heat the VICTREX AE250 organosheets nearly up to the melting temperature before inserting them into the injection molding press. The benefits resulting from the use of the Victrex composites include improved cycle times, reduced energy consumption, elimination of secondary process steps, reduced scrap and savings in installation expense.

-

Wabash MPI and Carver Inc. (Wabash, IN, US) are featuring their presses for composites fabrication, including hydraulic, pneumatic and electric units from 0.5- to 1,200-ton capacities and platen sizes from 6 by 6 inches to 6 by 12 ft. Custom press systems are also available for specific applications, as well as a variety of options including eject systems, data acquisition, recipe storage and bladder and core-pull circuits. Wabash MPI is celebrating its 75th anniversary in 2016 and offers standard and custom presses for compression molding, vacuum molding, ASTM testing, laboratory and R&D applications. Carver Inc. offers two-column and four-column benchtop, manual and automatic hydraulic laboratory presses suited for various materials research such as plastics, elastomers, lab testing, laminating, pharmaceuticals, analytical chemistry and other applications, including specimen preparation.

-

Zeus Industrial Products Inc. (Orangeburg, SC, US) is featuring its seamless composite release aid, FEP Lay-Flat Heat Shrink, a high-temperature release aid that is easily removed from the composite structure after curing and can withstand multiple autoclave cycles. This fluoropolymer heat shrink is said to easily and precisely recover over composite-forming mandrels or bladders, reducing layup and production time compared to films and tapes traditionally used in composite fabrication. Zeus will showcase its PEEK extrusions good abrasion resistance and temperature resistance up to 260°C. Zeus PEEK forms include extruded tubes, custom profiles, drawn fiber, insulated wire, spiral wrap, coatings and more.

-

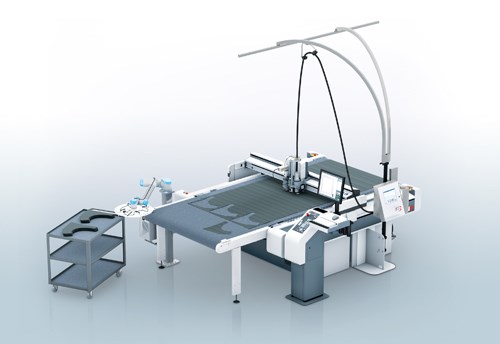

Automated cutting table specialist Zünd (Altstätten, Switzerland) is featuring the G3 M-1600 and collaborative UR robot. The UR robot does not require caging or other protected workspace and relieves the operator of the repetitive task of sorting and unloading. The cut parts are automatically stacked and can be removed any time without any interruptions to the production process. With a cutting area of 1,330 by 1,600 mm, the G3 M-1600 can handle anything from prepreg materials to dry weave and core materials, and even finished laminates. For cutting fiberglass and carbon fiber, Zünd offers the Power Rotary Tool (PRT), which is also protected against electrically charged or abrasive dust particles. For cutting materials with a low melting point, the RPM settings of the tool can be adjusted for specific material requirements. For cutting honeycomb and hard foam materials, the Pneumatic Oscillating Tool (POT) offers an air-drive system with an 8-mm stroke. The specialty router bit R62 is offered for routing cured parts.

Related Content

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreComposites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)