New CoTide project receives funding for composites tidal turbine development

A £7 million investment from the U.K. government seeks to scale tidal energy as part of the goal to scale renewables from 50 to 120-300 gigawatts by 2050.

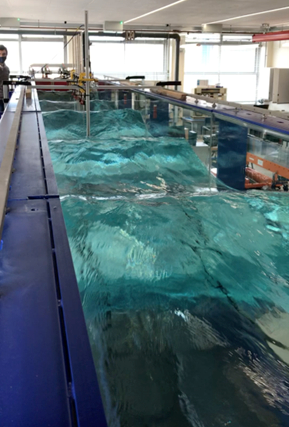

Photo Credit: University of Oxford

A £7 million Engineering and Physical Sciences Research Council (EPSRC) investment is bringing together three multidisciplinary teams from the U.K.-based universities of Oxford, Edinburgh and Strathclyde under the CoTide (Co-design to deliver Scalable Tidal Stream Energy) project to make renewable energy generation from ocean tides cheaper, more reliable and scalable.

Achieving the U.K.’s net zero objectives by 2050 requires the decarbonization of the region’s energy supplies and a huge expansion of renewable energy generation from the current 50 gigawatts (GW) to 120-300 GW. The powerful tides that surround the U.K. remain under-utilized but have potential as a source of greener power that could make a significant contribution to this goal. Plus, unlike the wind and the sun, tides ebb and flow at predictable times every day, thus providing renewable and reliable power.

CoTide will focus on developing state-of-the-art tidal stream turbine systems. Unlike more traditional tidal barrages and tidal lagoons that require turbines to be installed in structures such as dams or sea walls, tidal stream turbines are fixed directly out at sea in the line of the strongest, most suitable tidal flows. This reportedly makes them cheaper to build and install, and reduces their environmental impact.

Nevertheless, technical challenges remain, and tidal stream systems require careful design to maximize power while providing reliability in hostile marine environments characterized by corrosive seawater and unsteady loading caused by waves, turbulence and sheared flows.

To tackle this, the CoTide team includes a spectrum of expertise in all relevant areas, including:

- Device hydrodynamics

- Composites

- Rotor materials

- Corrosion

- Risk and reliability

- Environmental modeling

- System control and optimization

Together, the researchers will cooperate to develop and demonstrate holistic integrated tools and design processes that will significantly reduce costs by removing unnecessary redundancy and improving engineering solutions and processes. The project will be led by the University of Oxford’s professor of engineering science, Richard Willden.

The University of Oxford’s combined current and wave flume for ocean engineering research. Photo Credit: Richard Willden

“We have a huge opportunity as a country to harness the powerful tides that surround us and use innovative engineering to develop greater energy security and clean energy to help us meet our 2050 net zero goals,” Willden says. “This EPSRC investment in CoTide allows us to bring together world-class engineering expertise and drive forward the kind of creative, collaborative research that will ensure the U.K. remains a world-leader in tidal stream development and deployment.”

According to Dr. Lucy Martin, EPSRC’s deputy director for cross-council program, CoTide has 25 industry stakeholders and regulatory bodies, including EDF Energy Plc (London, U.K.), the Health and Safety Executive (U.K.), the Marine Energy Council (MEC, U.K.) and global manufacturer Arkema International (Colombes, France). This will ensure that CoTide’s outputs will deliver new tools, models, and processes that achieve direct industrial impact.

“We are beginning to see real commercial traction for tidal stream projects,” Sue Barr, chair of the UK Marine Energy Council, says. “In order for tidal stream energy to become more competitive, we need real step changes in system performance, reliability metrics and scalability of the technology. This will require integrated tools which can be utilized by the sector to not only improve performance, but also increase confidence for investors and guarantors.”

Additional information can be found on the CoTide website.

Related Content

Plant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

MAXBlade project to advance tidal energy generation with 13-meter composite blades

Recently launched 66-month MAXBlade project aims to harness tidal energy in the U.K. through a 70% increase in rotor swept area.

Read MorePlant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

Read MoreFastBlade partnership leads to rapid composite tidal blade facility testing

The University of Edinbourgh and Babcock International have dedicated the facility to speeding up the process of designing more durable, efficient structures.

Read More

.jpg;maxWidth=300;quality=90)