Smart carbon nanotubes for wind turbine blade anti-icing system

Fraunhofer Institute for Manufacturing researches develop energy-efficient method to free turbine blades from ice in seconds.

As reported in by nanowerk.com, wind turbines have rarely been built in very cold climate zones because the risk of ice formation on the rotor blades is too high for economical operation. Even though the wind often blows with great force, aerodynamic properties deteriorate when an ice layer forms on the rotor blades as temperatures drop below zero, reducing energy production and putting the turbine at risk for breakdown. Icicles breaking off are also a safety risk.

But now, an energy-efficient heating system frees these turbines from the ice in a matter of seconds. It is only switched on when water freezes. As part of the European Union’s Windheat Project, researchers at the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA, Stuttgart, Germany) are developing an energy-efficient ice detection and anti-icing (or de-icing) system for small wind turbine power generators that uses carbon nanotubes.

Existing anti-icing systems are energy-intensive, because they have to heat up the entire rotor blade regardless of whether its entirety is actually affected. The Windheat project is pursuing a different route. It divides the rotor blade into a variety of zones, each finished with a carbon nanotube (CNT) coating. A separate ice detector is then integrated into each individual CNT layer. “Our carbon nanotube coating only heats those zones that are actually iced up," says IPA scientist Anne Gerten. "These are the edges of the rotor blade, first and foremost."

The tiny, sensitive probes are constantly measuring temperature and humidity at the surface, and react to the slightest fluctuations to detect when water freezes. If ice is detected, the detectors switch on the heat element in a matter of seconds, to supply the corresponding CNT layer. Once the ice has melted, the heat is automatically switched off. “With the combination made out of CNT coating and sensors, we can target and heat the iced-up zones and essentially, only when it is actually required,” adds Gerten. The goal of the project is to increase energy efficiency by at least 18%, using this de-icing technique.

The CNT layer is just a few micrometers thick, and reportedly is easily applied to the rotor blade by spraying CNT onto a self-adhesive polymer film. Clear-coat insulates the coating and protects it from humidity and mechanical effects. The researchers selected this material because of its excellent mechanical properties. “In principle, these carbon nanotubes are wrapped layers of graphite that touch each other in various places. At these contact points, the electrical current is converted into heat,” Gerten explains.

Researchers used computer simulations to identify which areas of the rotor blades are especially susceptible to ice build-up. The edges of the blades are the most symptomati, confirmed through wind tunnel testing of prototypes realistic conditions at -30ºC in ice, rain, and wind speeds up to 120 km/h.

“We have applied affordable materials to both the sensors and the heating elements. That is an important precondition to making the anti-icing system feasible for serial production,” explains Dipl.-Ing. Sascha Getto, a colleague of Anne Gerten’s at IPA and researcher in charge of the wind tunnel tests. “We designed and built the prototypes for small wind turbine systems, but they are absolutely suitable for upscale retrofit.”

Getto considers deicing of airplane wings to also be a potential field of application for the Windheat System.

Related Content

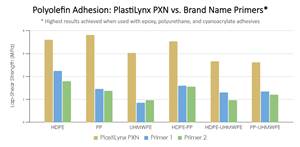

XlynX’s PlastiLynx PXN crosslinking primer enhances polymer adhesion

PFAS-free diazirine primer makes surfaces receptive to all manner of adhesives, including epoxies and polyurethanes, outperforming alternative options by 150-350%.

Read MoreScott Bader, Oxeco partner for high-performance bonding solution

Joint technology breaks barriers to bonding lightweight flexible solar panels to roofing structures made from aluminum, coated steel and composites.

Read MoreIPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MoreXlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)