UMaine dedicates ocean engineering lab for wind energy testing

The lab will be used to test offshore wind turbines and similar structures, and provide facilities for thermoplastic composites research and development.

During a laboratory dedication at the University of Maine (Orono, ME, US) on Nov. 23, the Harold Alfond Foundation announced a $3.9 million grant to the University of Maine to match $9.98 million already raised, formally establishing the Harold Alfond W2 Ocean Engineering Laboratory and Advanced Manufacturing Laboratory at the Advanced Structures and Composites Center on campus.

“We are investing in people and infrastructure that will support ocean engineering, and advanced manufacturing education and research, and grow Maine jobs,” says Gregory Powell, chairman of the Harold Alfond Foundation.

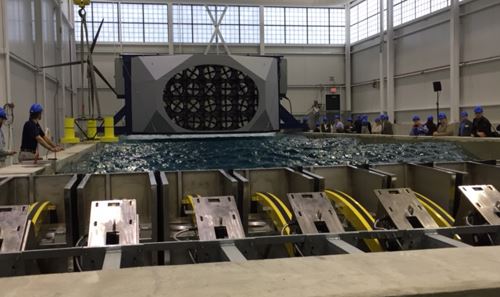

The Ocean Engineering Laboratory will prototype coastal and offshore structures, including ocean energy devices, ships, aquaculture facilities and oil and gas structures under extreme wave, wind and current environments.

The Advanced Manufacturing Laboratory for thermoplastic composites will use digital, additive and robotics manufacturing to reduce cycle time and cost. Structural thermoplastics are recyclable materials that could transform composite materials use in cars, ships, boats and aerospace applications. In June, the Composites Center received $497,965 from the National Institutes of Standards and Technology to develop a national road map for advanced manufacturing of structural thermoplastics composites materials.

The total construction, equipping and start-up of the new laboratories over the first three years will cost more than $13.8 million. Of that, the center had raised more than $9.98 million through four grant competitions, including the U.S. Economic Development Administration, National Science Foundation, National Institute of Standards and Technology, and Maine Technology Institute, as well as a Maine voter-approved bond, supported by the Governor and Maine Legislature in June 2015.

The Alfond Foundation naming gift of $3.9 million will help complete the equipping of the facility, hire engineers for the start-up in 2015-16, and fund graduate and undergraduate students over three years to help start-up the facility.

“I am delighted that after years of hard work, the University of Maine is establishing world-class research capabilities in ocean engineering and advanced composites manufacturing to help Maine and the nation improve our industrial competitiveness in boatbuilding, renewable energy and aquaculture, and to help protect our coastal cities from major storms,” says U.S. Sen. Susan Collins. “Maine has a long and impressive history in both boatbuilding and composites manufacturing. The important investment in this laboratory at UMaine builds on our state’s tradition of excellence in ocean engineering. Throughout my service in the Senate, I have been a steadfast supporter of the Composites Center, and do thank the Alfond Foundation, the National Science Foundation, the U.S. Department of Commerce, the Maine Technology Institute and Maine voters for their participation in making this $13.8 million research facility a reality in Maine.”

“The University of Maine has long been a pioneer in ocean research and engineering. With the state-of-the-art Alfond Ocean Engineering and Advanced Manufacturing Laboratories, the students and faculty at UMaine will be able to build on this impressive legacy and help grow Maine’s marine economy,” said U.S. Sen. Angus King. “I commend the Alfond Foundation for its dedication to providing a brighter future for Maine, and for its continued commitment to giving our students the opportunities they need to grow, learn and thrive.”

“These will be the only labs of their kind in Maine with world-class capabilities to educate students and conduct cutting-edge research and development,” says professor Habib Dagher, executive director of the UMaine Composites Center. “The R&D will support the growth of the ocean economies and shipbuilding sectors in Maine and the nation, as well as the growth of digital and additive manufacturing of thermoplastic composite materials.”

“Two integrated world-class research laboratories will be established in Maine through this unique partnership with the Alfond Foundation,” said UMaine President Susan Hunter. “This advancement in one of UMaine’s Signature Areas of Excellence creates unparalleled opportunities for students and researchers, and supports marine-related economic development in Maine.”

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreHexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More