Veelo Technologies debulking system enables OOA composite aircraft rotor blade processing

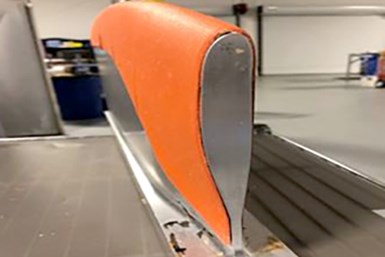

In-situ heating blankets offer a highly drapable solution for uniform heating coverage over complex surface areas.

All photo credit: Veelo Technologies

Veelo Technologies (Cincinnati, Ohio, U.S.) announced on Feb. 23 that its patented heating blankets, the VeeloHEAT Caul, can be applied to composite aircraft rotor blades. Tailored for use in composite debulking and bonding applications, the system enables in-situ hot debulk, eliminating the need to transport long and bulky rotor blades to an oven. This in turn improves build and repair rates while also reducing scrap.

According to the company VeeloHEAT Caul is designed for flexibility and pliability, enabling a highly drapable solution that provides uniform heating coverage across the large and geometrically complex surface areas found on rotor blades. The heating blankets are also said to easily accommodate custom shapes and large tools with minimal or few bridging issues. They are durable and damage resistant and are offered in an optional FKM-based heater system for high performance and material compatibility.

Use of VeeloHEAT Caul on aircraft rotor blade.

“Our VeeloHEAT solution is currently used by the aerospace composites industry to bond and repair multi-million-dollar composite aerostructures,” says Mr. Joe Sprengard, Jr, president and CEO at Veelo. “We are helping them accelerate adhesive cure, perform faster composite repairs and improve the debulk processes. For rotor blades specifically, the net-shape draping that occurs with our blankets can help a manufacturer or repair facility realize substantial savings and improvement in build and repair rates. We provide an effective alternative to taking these blades to the oven.”

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

-

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.