Hexcel introduces G-Vent technology for thick, OOA marine structures

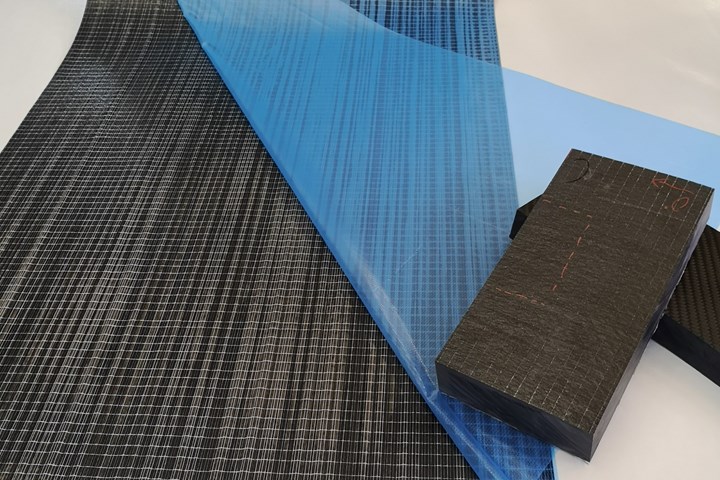

Hexcel marine prepregs are available with G-Vent integrated, enabling out-of-autoclave processing with reduced time, cost and autoclave-comparable porosity for highly loaded masts and foils without debulking.

Photo Credit, all images: Hexcel Corp.

Hexcel Corp. (Stamford, Conn., U.S.) has leveraged its experience in aerospace and wind energy to develop a novel technology for out-of-autoclave (OOA) processing. It is reported to deliver significant reduction in process time and cost for marine manufacturers without compromising mechanical performance.

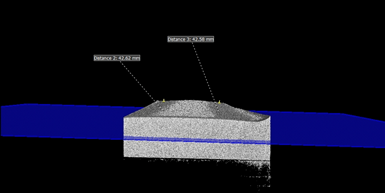

Hexcel’s G-Vent technology targets OOA processing of highly loaded, thick section marine structures such as masts, foils and wind-assisted ship propulsion (WASP) components. Hexcel’s full range of marine prepregs are now available with integrated G-Vent technology, reducing the requirement for debulking steps and ensuring very low porosity (<1%) irrespective of the laminate thickness, according to the company.

To evaluate G-Vent, Hexcel completed a test program with Q.I. Composites Srl (Piverone, Italy), a company that performs non-destructive testing (NDT) in performance marine applications. The program evaluated HexPly 40-layer prepreg samples prepared with G-Vent technology. Carbon fiber panels made with no debulking revealed approximately three times less porosity than those using a typical 10-minute debulk with every second ply. Ultrasonic and computed tomography (CT) scan analysis by Q.I. Composites confirmed the void content results with porosity levels in line with state-of-the-art autoclaved carbon prepreg foils. Hexcel also notes that key tensile, compressive and interlaminar shear strength results were also higher for the G-Vent panels.

Related Content

-

One-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.