JEC World 2018 preview: Porcher

Porcher Industries (Eclose-Badinières, France) will have a talented team of textile, composite and chemical engineering experts in Paris to present their latest innovations at JEC World 2018.

Porcher Industries (Eclose-Badinières, France) will have a talented team of textile, composite and chemical engineering experts in Paris to present their latest innovations at JEC World 2018. Porcher Industries’ five business units will present market specific technical textile and thermoplastic composite solutions at Stand M28 in Hall 6.

Porcher Industries and Stelia Aerospace (Toulouse, France) will jointly present a unique new carbon fiber-reinforced thermoplastic airframe component. The Arches Box TP research project will be a key focus at JEC World 2018 with both companies presenting their technical innovations and displaying components at the show. Porcher Industries will present thermoplastic strengthening frame components that were developed for the Arches demonstrator on the Porcher booth, while STELIA Aerospace will also display the full-scale thermoplastic fuselage demonstrator within the Planets section at the show. Having been nominated together as a JEC Innovation Award Finalist (along with partners SINTEX NP, Compose Tool, CETIM, Aviacomp and Institut de Soudure), Porcher Industries and STELIA Aerospace will co-present a paper titled “Design to Cost Concept for Thermoplastic Laminates” on Wednesday 7th March at JEC World 2018. Presented by Pierre-Yves Gandon, Aerospace Technical Support, Porcher Industries and Loic Le Lay, Composite Manufacturing, STELIA Aerospace, the paper will highlight innovations that were used for the strengthening frames of the Arches Box aircraft fuselage. Porcher Industries has developed a new surface modification for the carbon fiber itself as well as a specific low crimp weaving technology for the heavier 12k tow. The combination of these two innovative processing methods resulted in the more cost effective 12K carbon/PEKK laminates exhibiting the same mechanical performance level as the standard 3K carbon/PEKK laminates.

Porcher Industries will also showcase its unique technology of dry fibers for automated fiber placement (AFP) offering multiple options of binders (thermoset or high-temperature thermoplastic) and carbon fibers for out of autoclave (OOA) processes in aerospace and defense.

In addition, Porcher Industries will be showing its full range of technical textile composite solutions for the automotive sector, from woven fabrics to PiPreg thermoplastic prepreg materials and pre-consolidated cured laminates. Furthermore, the company will showcase an enhanced thermoplastic portfolio with the newly introduced PolyPreg, a co-mingled glass and polypropylene fabric. These solutions are available for the most demanding applications in vehicle manufacturing.

Following the acquisition of the entire operations of technical glass fabrics producer P-D Interglas Technologies, Porcher Industries has now added a non-combustible line of FLAMLINE-glass fabrics to their Building Business Unit. Presented at JEC World 2018, these FLAMLINE fabrics are used when the highest levels of fire, smoke and toxicity protection are required in applications such as wall panels for acoustical insulation, stage curtains, and upholstery interliners for furniture. The Porcher Industries Building team will also showcase textile solutions for thermal, acoustical, and solar protection across the construction market.

Also on display: its Greenlite range of fabrics along with some examples of end-use applications in sporting goods. Previously recognized with a JEC Innovation Award, Greenlite fabrics use low density cellulose fibers to produce a range of different woven styles that are biodegradable, highly compatible with bio-resins and suitable for large volume manufacturing of bio-based composite parts. As well as their contribution to sustainability, Greenlite composites also exhibit exceptional vibration dampening characteristics, improving comfort and reducing fatigue in raquet sports in particular

Alongside the full range of technical textiles offered, Thermoplastic Composite materials also provide an almost limitless set of solutions within the Industrial sector. One possibility is the replacement of metallic parts, offering excellent chemical resistance without any additional surface treatment or coating. Porcher Industries Industrial will showcase long lasting high-performance carbon/PEEK parts used in specialist pumps from the chemical production industry.

Related Content

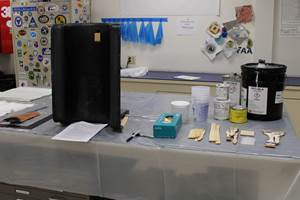

Fostering best practices for wet layup procedures

As fabricators continue to manufacture composite tools and parts using an open mold, wet layup process — often with mixed success — it’s important to stress proper preparation, materials, application methods and standardization.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More