IMDEA Materials demonstrates recyclability of CNT sheets

Researchers have proven it’s possible to recycle CNTs at the macroscopic scale with nearly 100% retention of mechanical and electrical properties, removing a hurdle to sustainable CNT-based fiber, sheet and textile adoption.

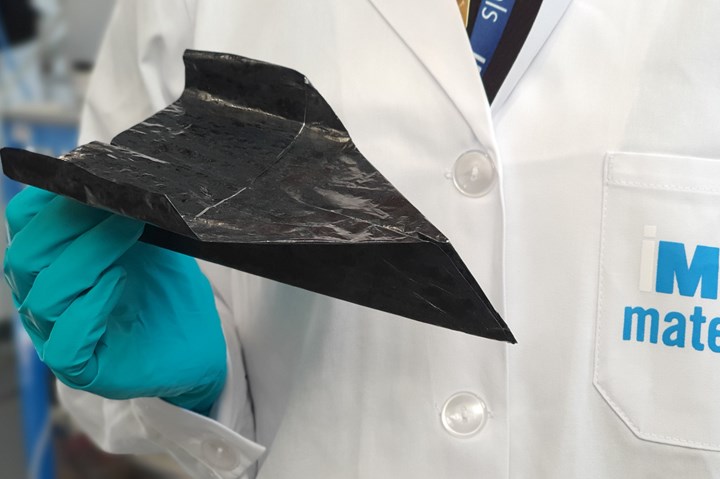

The recycled carbon nanotube sheets retain their key mechanical properties, including their flexibility. Source | IMDEA Materials Institute

Researchers at IMDEA Materials Institute (Madrid, Spain) have recently demonstrated the recyclability of high-performance carbon nanotube (CNT) sheets while maintaining their essential mechanical and electrical properties.

Outlined in the paper, “Network structure enabling re-use and near full property retention in CNT sheets recycled from thermoset composites,” published in Carbon, the findings represent an advance in sustainable nanostructured materials and holds promise for CNT fibers, sheets and textiles to play a pivotal role in the future transition to green energy.

“Even 3 years ago, there was little interest in recycling CNT-based materials and this research is the first attempt in this direction,” contends Dr. Anastasiia Mikhalchan, senior research associate at IMDEA Materials Institute. “It demonstrates that high-performance materials made from carbon nanotubes can be reused as structural reinforcement or electrical conductors. This is due to the fact that neither their continuity, alignment and mechanical properties, nor their conductivity, is affected by this recycling process.”

“These [materials] will be able to displace widespread CO2-intensive materials, such as conventional carbon fibers and some metals like copper, decreasing our future CO2 emissions footprint,” Mikhalchan continues. “The work uses carbon nanotubes rapidly grown and directly assembled into freestanding network materials by means of a floating catalyst chemical vapor deposition [FCCVD] synthesis process.”

According to IMDEA, these CNT fibers and sheets possess high structural toughness and flexibility as well as high mechanical, electrical and thermal properties which enables their use in structural reinforcement in composite laminates, as well as printable strain/stress sensors, electrical conductors, flexible battery anodes, etc.

With the global CNT production capacity increasing annually, recycling CNT-based materials has become a pertinent topic. The research conducted by IMDEA Materials is expected to catalyze the scale-up of manufacturing high-performance CNT materials and accelerate their adoption by industry.

This work is supported by the Rice University-led Carbon Hub Initiative of which IMDEA Materials’ Multifunctional Nanocomposite research group, led by Dr. Juan José Vilatela, is an active member. The team behind this breakthrough, alongside Dr. Mikhalchan, includes former IMDEA Materials intern Sergio Ramos Lozano, IMDEA Materials PhD student Dr. Andrea Fernández Gorgojo, professor Carlos González and Dr. Vilatela.

Related Content

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.