Shin-Etsu Chemical Co. to manufacture, market new hydrocarbon resins for 5G electronics, aerospace

Developed per a licensing agreement with materials company Novoset LLC, the resins are said to possess ultra-low dielectric loss properties for electronics.

Materials company Novoset LLC (Peapack, New Jersey, U.S.) announced on Dec. 26 that it has signed a licensing agreement with Shin-Etsu Chemical Co. Ltd. (Tokyo, Japan) for the manufacturing and marketing of modified hydrocarbon resins based on Novoset’s intellectual property, which will target applications in electronics, automotive and aerospace.

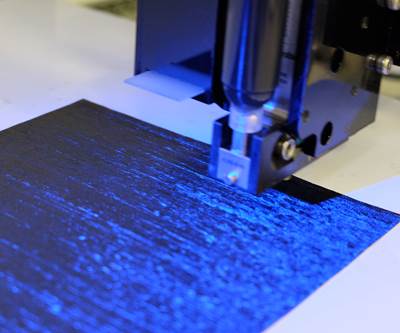

The new resins are said to exhibit ultra-low dielectric loss properties at high frequencies, low coefficient of thermal expansion (CTE), very low moisture absorption, high glass transition temperatures (Tg) and long-term thermo-oxidative stability at 250°C.

These products are targeted for a range of 5G applications such as chip encapsulation, underfill, molding compounds, millimeter wave base station infrastructure for smartphones, high layer count printed circuit board (PCB) servers, routers for cloud computing and semiconductor packaging. Novoset says that these resins are specifically designed for use in devices enabling next-generation 5G technologies like Advanced Driver Assistance Systems (ADAS).

These products are also reportedly suitable for various aerospace applications where ultra-low dielectric, low moisture properties and high Tg are required. In addition, the materials can be used in aerospace processes such as resin infusion, hot melt prepreg, filament winding and other liquid processes.

Novoset officials said in a press release, “We are pleased to collaborate with Shin-Etsu Chemical, Japan to commercialize these unique products to address material gaps and difficult-to-process current 5G materials (targeted to millimeter wave substrates, antennas) such as liquid-crystal polymers (LCP), polyimides (PI) and polytetrafluorethylene (PTFE). Shin-Etsu Chemical is our ideal collaborator due to their in-house 5G applications and global footprint in semiconductors and other high-end industries.”

The resins were developed at Novoset Technology Center in Berkeley Heights, N.J., U.S. Under this agreement, Shin-Etsu Chemical Co. Ltd. will manufacture the resins globally in the relevant electronics industries and market the products under SLK name. Novoset will market the products in aerospace, oil and gas, and other industries, and will continue to improve and expand the range of products according to market needs.

Related Content

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Nanomaterials: Products, supply chain mature for next-gen composites

Development spans 3D and thermoplastic nanocomposites, nano-CMCs for hypersonics and nanomaterials safety and toxicity.

Read More5G-enabled smart cities bring opportunities for pultruded composites

A recent report explores the utility of radio frequency-transparent pultruded composite materials for integrating 5G mobile networks into urban infrastructure.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;width=70;height=70;mode=crop)