Sensors

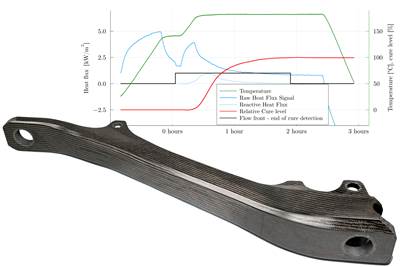

Speeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

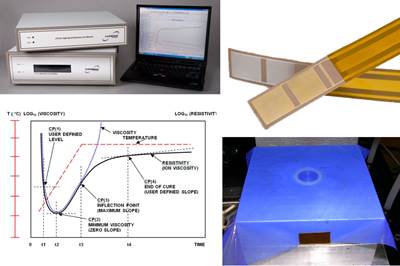

Read MoreCombining AC and DC dielectric measurements for cure monitoring of composites

Lambient Technologies advances dielectric analysis (DEA) for more reliable, affordable composites manufacturing.

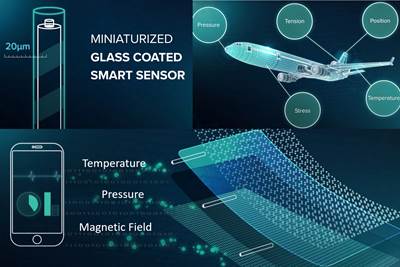

Read MoreContactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

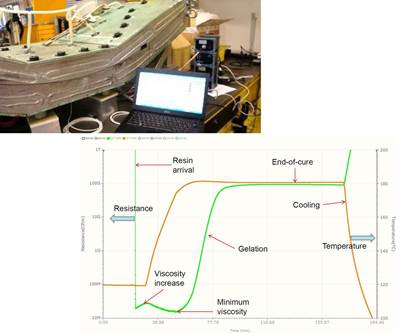

WatchDC dielectric sensors for industrial composites production

Synthesites in situ process monitoring enables cure decisions based on real-time Tg evaluation that can reduce cure cycles by up to 50%.

Read MoreThermoplastic overmolded thermosets, 2-minute cycle, one cell

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

Read MoreMeasuring temperature inside composites and bondlines

ThermoPulse sensors offer Industry 4.0 temperature measurement and digital cure cycle management for bonded composite repairs, laminates and more.

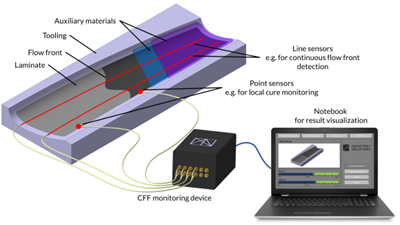

Read MoreSensors for monitoring resin infusion flow front and cure

InFactory Solutions commercializes technology to provide real-time resin impregnation and cure data across composite parts for zero-defect, intelligent process chains.

Read More