Composite Trusses For Large Structures?

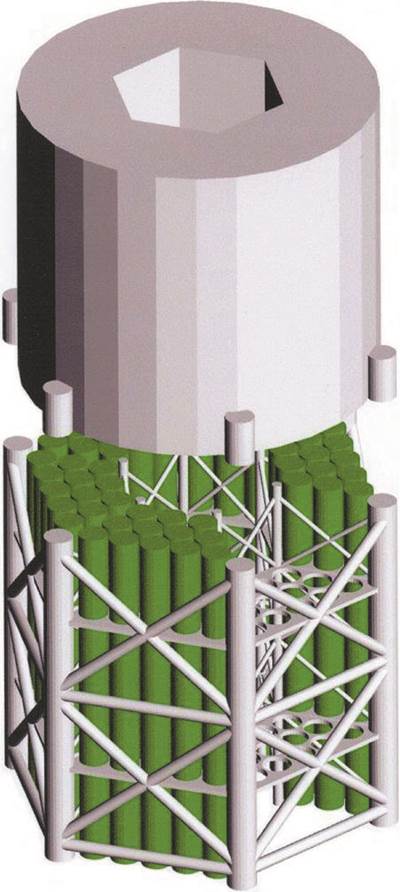

Ebert Composites Corp. (Chula Vista, Calif., U.S.A.) is marketing a composite truss concept for large structures that has potential for offshore application. Since 1992, the company has focused on the development of large, all-composite lattice-type power transmission towers to replace galvanized steel towers.

Ebert Composites Corp. (Chula Vista, Calif., U.S.A.) is marketing a composite truss concept for large structures that has potential for offshore application. Since 1992, the company has focused on the development of large, all-composite lattice-type power transmission towers to replace galvanized steel towers. The corrosion- resistant towers are assembled entirely with interlocking “snap-fit” joints originally designed by Brandt Goldsworthy & Assoc. (Torrance, Calif.).

Ebert has formed a joint venture with Strongwell Corp., called Strongwell Ebert LLC (also based in Bristol, Va.), which will pultrude the truss profiles. Much of the recent development focus has been on optimizing the fiber architecture of the pultruded parts — Ebert received a $2 million National Institute of Standards and Technology (NIST) Advanced Technology Program (ATP) grant in late 1998 to perfect its three-dimensional fiber deposition process. “We have developed a fiber architecture that essentially creates a quasi-isotropic profile that can be machined like steel,” says Ebert’s David Johnson. The fiberglass and vinyl ester truss elements are similar in size to steel bar stock, with strength almost equal in all directions, but with one-third the weight of steel.

An 84 ft/26m tall, 6,000 lb/2,700 kg tower prototype was assembled at the Electric Power Research Institute (EPRI) facility in Haslet, Texas and tested to determine its performance in simulated wind load and ice load conditions. Strain gauges and laser targets were installed to check loading and deflection. In the worst-case test, approximately 20,000 lb/9,000 kg lateral load and 35,000 lb/16,000 kg vertical load was applied. Three towers have performed successfully since March 1996 in a coastal location in Southern California.

According to Johnson, the truss principles can be applied to many offshore applications, including the platform structure, decking, derrick structures and space-frame cantilevered structures that support helicopter pads. Either vinyl ester resin with fire-retardant additives or phenolic resin can be used to achieve specified fire resistance.

Toray Industries Inc. (Tokyo, Japan), together with Shimizu Construction and Japan Aluminum, has developed a modular truss design for large structural applications that is extremely strong and stiff, thanks to its carbon fiber construction. After extensive laboratory tests, the truss system was validated in a 50,000 ft²/4,645m² exhibition hall in Fukushima, Japan.

The truss uses filament wound carbon fiber/phenolic tubes that have 55 percent fiber volume. Each end of a wound tube is riveted to an aluminum “nose cone,” which, in turn, is screwed into an aluminum hub with a moly-chrome bearing bolt. The hubs connect several struts to form a lattice array, the design of which can vary depending on the specific application.

Testing data show that at 400°F/204°C, the truss tubes maintained more than half of the compression strength demonstrated at ambient temperature, with tensile and bearing strength remaining essentially unchanged.

At one-third the weight of a steel truss, the carbon fiber version is a good candidate technology for offshore platform construction, including flare booms or deck structures, because of reduced construction time, ease of assembly, corrosion resistance and high stiffness-to-weight ratio. With 80 percent lower maintenance costs than steel, its higher material costs can be justified in a matter of a few years.

Related Content

The making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreRead Next

Changing The Paradigm

In Gibson’s opinion, large composite structures will be proven onshore, in civil infrastructure. “What will happen is that large pultruded parts and those made with other means will become commonplace,” he maintains, “and then the technology will migrate to other areas, including offshore oil.” Dr. Char

Read MoreA Different, All-Composite Approach

Fiberglass Structural Engineering Inc. (FSE, Bellingham, Wash., U.S.A.) has patented its innovative concept for a hybrid fiberglass and steel platform. Approximately 50 percent of the volume of a conventional steel spar hull would be replaced by hollow filament-wound Eglass and vinyl ester tubes, from 10 ft to

Read More