CW’s Inside Manufacturing article series focuses on the step-by-step manufacturing processes, materials and technologies used to fabricate composite parts and structures for all of the end markets served by the composites industry.

Take a look here at our all-time top ten Inside Manfuacturing stories, according to Google Analytics.

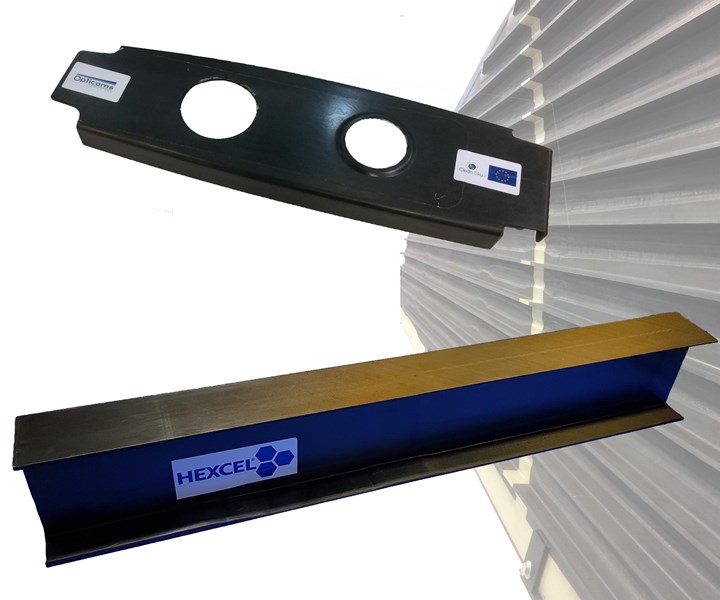

10. Compression RTM for production of future aerostructures

Automated preforming and 5-min resin infiltration show a way forward for lower-cost CFRP primary structures.

9. Spar forming simplified

Adapting its Automated Stiffener Forming (ASF) technology to build spars directly in female molds, Northrop Grumman Innovation Systems anticipates dramatic drops in cycle time and manufacturing cost.

Photo Credit: NGIS

8. Optimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

7. Advancing the OOA infused wing box

MTorres integrates lower cover, front and rear spars into unitized flying demonstrator using one-shot, low-cost, portable production.

6. Easy-to-use kits enable infield repair of composite structures

Portable kit enables patch repairs using UV-cure glass fiber/vinyl ester or room-temp stored carbon fiber/epoxy prepregs and battery-powered curing equipment.

Metrology, robotics and inline inspection cut cost, reduce shimming and enable future automated production of three vertical tail planes per day.

Photo Credit: Airbus / CTC / Fraunhofer IFAM

4. Building the Museum of the Future

FR composite panels provide structure, sealing and iconic facade for pioneering architecture in Dubai.

3. Braided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

Photo Credit: Spintech Holdings Inc.

2. Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

1. High-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

Related Content

-

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

.jpg;maxWidth=300;quality=90)