Machining/Drilling of Composites

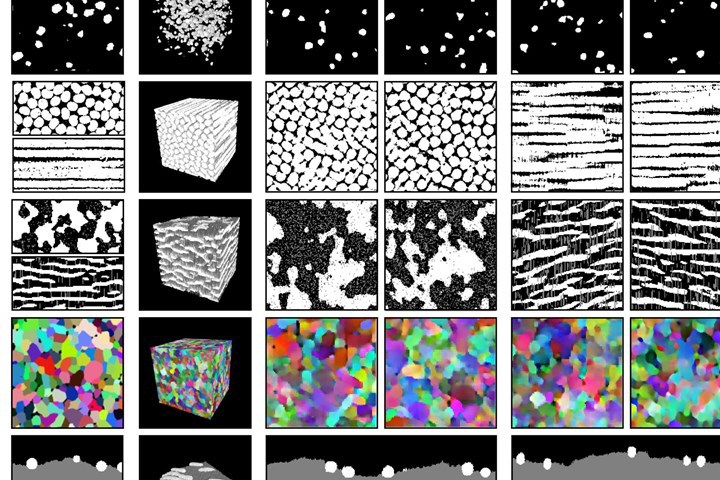

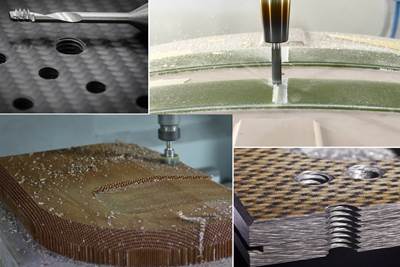

Machining and drilling processes in composites present unique challenges due to the heterogeneous nature of these materials. Composite structures, often composed of different layers and materials, require specialized techniques to maintain integrity and precision during machining or drilling. Traditional methods used for metals can cause delamination, fiber pullout, or damage to the composite structure. Therefore, specialized tools, such as diamond or carbide-tipped equipment, and specific cutting parameters are employed to ensure clean cuts without compromising the material's integrity.

Latest Machining/Drilling Articles

VIEW ALLRoMaNi 2 project enhances industrial robot flexibility for composites, metals machining

Newly developed milling kinematics on a linear axis enables versatile and efficient machining with up to 0.1-millimeter production tolerance.

Read MoreDeveloping milling for CMC because grinding takes too long

Economical processes that can cut machining time by 70% are being tested on aeroengine turbine blade demonstrators by Hufschmied and DLR in the SCANCUT project.

Read MoreQueen’s University Belfast presents research in thermoplastic drilling performance optimization

Researchers have published findings from a multi-objective optimization study on carbon fiber-reinforced PEKK drilling in an effort to better understand the material for use in aviation fastenings.

Read MoreNorco invests in CNC, kit cutting capability expansion

Transition from internal to external demand over the last few years has evolved Norco’s machining and composite kit cutting equipment, and now includes material outsourcing and digital engineering services.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

WatchCFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MoreKnowledge Centers

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORE

Review the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

LEARN MORE

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORELatest Machining/Drilling News And Updates

Hufschmied Zerspanungssysteme, specialist in composites machining, establishes branch in the U.S.

Supplier of material- and process-optimized cutting tools and technology for CFRP, GFRP and CMC, as well as metals, opened its Chicago facility August 1, 2024.

Read MoreZimmerman highlights five-axis portal milling line

The FZU22 machines various workpiece shapes, sizes and materials including carbon fiber and other fiber reinforcement options.

Read MoreMel Composites adds Rohacryl processing to customized core offerings

Addition of machining services for the Evonik structural foam brand expands Mel’s range of foam core delivery.

Read MoreNet-shape machining services available for structural foam core

CAMX 2024: In addition to its distribution of various product materials for the composites industry, Technology Marketing Inc. now assists in machined net-shaped Rohacell structural foam core to customer requirements.

Read MoreVericut version 9.5 maximizes efficiency, minimizes downtime

Latest CGTech software release adds improvements within the core product while improving user experience and practically automating NC program optimization.

Read MoreIdeko research validates robotic solution for clean, precise composites machining

Designed through the European Fibremach project, the equipment provides a greater increase in precision and machining efficiency and integrates a monitoring system that ensures part quality.

Read MoreFeatured Posts

Filament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreAI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

WatchFrom the CW Archives: Drilling is not for the faint of heart

This edition of From the CW Archives revisits CW’s first plant tour — a visit to the F-35 FAL in Fort Worth, Texas — and a story by Ginger Gardiner a few years later. Both offer lessons on how to perform stacked drilling through composite and metallic materials.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreLaboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites

Four-year, 12-million-euro LaiLa project with Helmut Schmidt University combines R&D with industry collaboration to solve real production pain points, validate solutions in digital lab/model factory at CTC and transfer knowledge to supply chain including customized training.

Read More

.jpg;maxWidth=300;quality=90)

.jpeg;maxWidth=400;quality=70)