Composites Processes

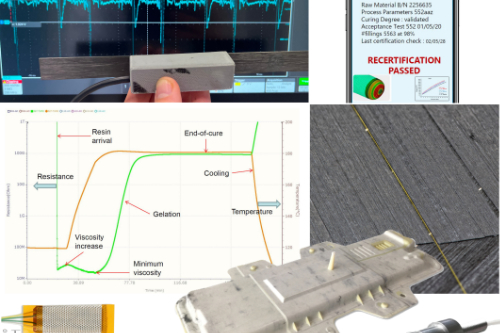

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Narrow Your Processes Search

Latest Processes Articles

VIEW ALLVIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

WatchSubmit abstract to speak at CW Bonding and Welding Tech Days in April

Online event in spring 2025 will feature six presentations exploring reliable methods for the assembly and joining of composite components. Abstract deadline is Feb. 3, 2025.

Read MoreGurit reformulates epoxy products with bio-content

Prime resin infusion and Ampreg wet laminating portfolios are now made more environmentally conscious as a standard.

Read MoreDesign for manufacturing, assembly and automation enables complex CFRP telescope supports

Airborne delivered two mirror support structures for the FYST and SOLAT telescopes, assembling 26,300 components while maintaining near-zero CTE, strict tolerances on 6.5 × 6.5 × 1.8-meter assemblies.

WatchPUR composite sandwich panels for 3D automotive parts, high-volume panels and more

At its U.S. sites, Ascorium produces glass fiber/PUR 3D parts via semi-automated molding, high-volume flat panels via a continuous line while working toward bio-based PUR and recycling.

WatchVIDEO: Precision fabrication of honeycomb materials

MachineTek showcases its precision fabrication of honeycomb materials at CAMX 2024.

WatchKnowledge Centers

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

This CW Tech Days event will explore the technologies, materials, and strategies that can help composites manufacturers become more sustainable.

LEARN MORELatest Processes News And Updates

McClarin Composites partners with ExxonMobil to accelerate high-speed RTM

Multimillion-dollar investment to drive next-gen automated RTM technology will open new applications and markets for composites OEMs.

Read MoreNorco enhances composites expertise via large-format AM equipment investment

3D printers, five-axis machining and software equipment additions to a dedicated CNC facility will support growth of Norco’s existing capabilities and build market diversity.

Read MorePolar Technology announces filament winder installation

Machine addition to a larger dedicated cell will support the company’s higher volume composites manufacturing capabilities and future growth plans.

Read MoreComposite Integration adds real-time resin degassing measuring to Ciject equipment

Ciject resin infusion and injection machinery now offers real-time resin degassing measurement technology that uses sensors and software to continuously monitor the state of resin during the degassing process.

Read MoreORNL demonstrates lightning strike protection tech for composites

Researchers, led by Vipin Kumar, developed a low-cost, recyclable carbon fiber wind turbine blade tip that showed resilience to high-voltage lightning strikes, with more innovations in store.

Read MoreCaracol, AES forge LFAM-centered partnership

AES’ LFAM services, backed by Caracol’s Heron AM 3D printing platform, target an innovation boost in aerospace- and defense-specific composite and metal applications.

Read MoreFeatured Posts

Braided thermoplastic composite H2 tanks with co-consolidated molded boss areas to fit EV battery space

BRYSON project demonstrates possible designs, automated manufacturing and low permeability concepts, including EVOH liner and novel PPA matrix.

Read MoreDetermining steel/composite failure load of bonded repair assemblies

Bureau Veritas and partners use a novel equivalent interface test specimen and simulation to predict failure load in bonded composite patch repairs to steel structures.

Read MoreLarge-format AM speeds plug production for manufacture of composite boat molds

Hungarian manufacturer Rapid Prototyping transitioned its conventional foam milling process to 3D printing to produce faster, higher quality, recyclable foam plugs and composite boat molds.

WatchVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

WatchAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreOptimized CFRP gantry beam enhances Ultimate cutting machines

CompoTech, Kongsberg PCS collaboration integrates foam-cored design, automated placement of pitch and PAN fibers to achieve award-winning increase in speed and precision.

Read More

.jpg;maxWidth=300;quality=90)