Composites Molds/Tools

Composite parts are typically formed in molds, also known as tools (see CompositesWorld’s introduction to fabrication methods for a primer on manufacturing methods). Tools can be made from virtually any material. For parts that will be produced in low quantities and can be cured at ambient or low temperature, or for prototype parts, where tight control of dimensional accuracy isn’t of prime importance, materials such as fiberglass, high-density foams, machinable epoxy boards or even clay or wood/plaster molds often are suitable.

Latest Molds/Tools Articles

VIEW ALLJuggerbot 3D announces MSU, ORNL as partners for hybrid LFAM composites project

Air Force-funded initiative looks to LFAM thermoset, thermoplastic advancement for fast, inexpensive composite tooling production.

Read MoreBase Materials introduces BE890 epoxy tooling board

Base Materials introduces a high-performance, toughened epoxy tooling board designed for thermoforming and vacuum forming processes, direct-to-part applications and more.

Read MoreAirtech, Ascent Aerospace partner to accelerate AM tooling adoption

A combination of Airtech’s 3D printing materials and Ascent’s production capabilities aim to support increased use of composite additive tooling in spaces like defense and aerospace.

Read MoreJamco America partners with Airtech for 3DP tool recycling

Aerospace manufacturer joins forces with composite materials company to achieve sustainable manufacturing practices that overcome traditional composite layup tooling.

Read MoreComposite tooling specialist displays compression mold capabilities

CAMX 2024: Century Tool specializes in the in-house design, build and run-off of dimensionally large parts and Class A surface tooling.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

WatchKnowledge Centers

Review the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

LEARN MORE

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORE

During CW Tech Days: Thermoplastics for Large Structures, experts explored the materials and processing technologies that are enabling the transition to large-part manufacturing.

LEARN MORELatest Molds/Tools News And Updates

Norco GFRP molds meet high-quality cast concrete beam production needs

A project with P&M successfully achieved manufacture of six 20-meter-long architectural beams for an R&D facility with near-seamless surfaces and on a tight production schedule.

WatchAdapa reconfigurable mold technology replaces one-off fabrication

From hand lamination to thermoforming, the company’s adaptive mold enables the production of complex, curved structures without the waste or time associated with more traditional molds.

Read MoreFyous launches infinitely reusable manufacturing mold tech

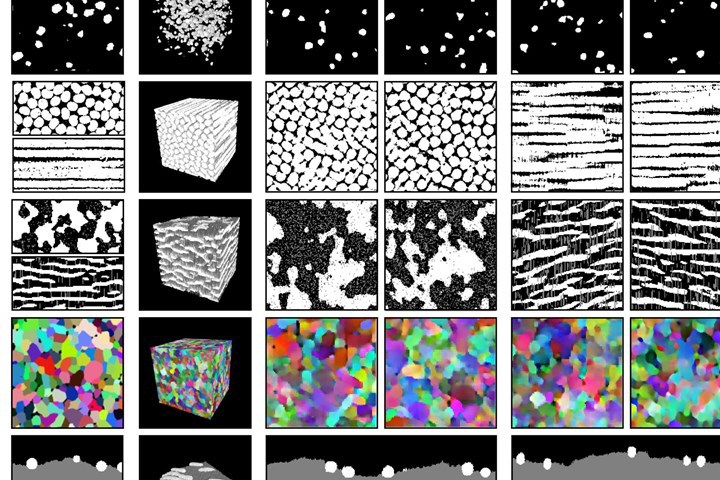

PolyMorphic Moulding technology uses 28,000 digitally controlled pins to create a shape from a 3D CAD shape in less than 20 minutes, achieving zero waste and enabling parts production 14 times faster than 3D printing.

Read MoreTPI, UMaine, ORNL to leverage world’s largest polymer 3D printer for wind turbine tooling

Ingersoll Masterprint LFAM printer will be used to produce and demonstrate 100% recyclable tooling that could cut large composite blade development cycles and tooling costs by as much as 50%.

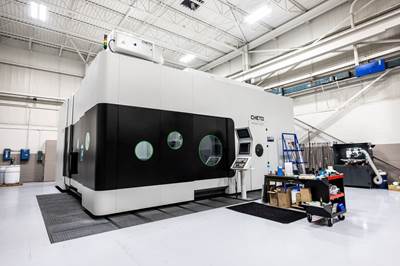

Read MoreCentury Tool investment boosts efficiency, capability in tooling for composites

Designer and builder of compression molds for composite structures installs seven-axis CNC deep-hole drilling and milling machine to improve productivity.

Read MoreMassivit, Sika to co-brand digital tooling materials for Massivit 10000 series

Strategic MOU initially introduces SikaBiresin CIM 120 and SikaBiresin CIM 80 to serve crucial composites market needs for 3D printing tooling, prototyping and more.

Read MoreFeatured Posts

Optimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

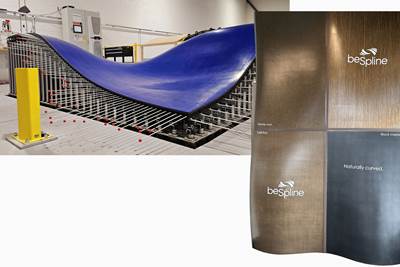

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

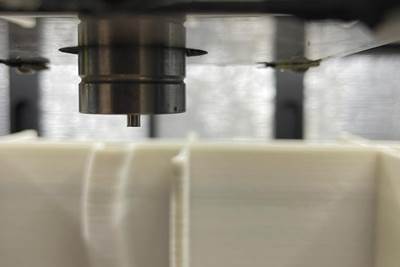

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

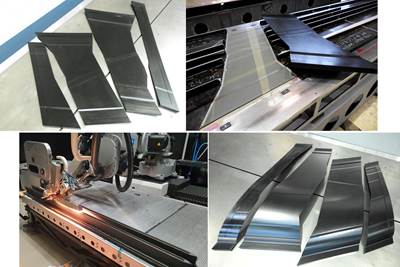

Watch3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MorePlant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

WatchNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read More

.jpg;maxWidth=300;quality=90)