Cyanate Ester in Composites

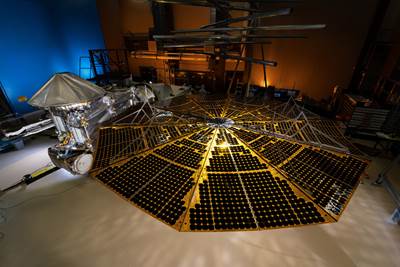

NASA's Lucy spacecraft, built by Lockheed Martin, begins journey to Jupiter's Trojan asteroids

Launched for its 12-year journey in space, the Lucy aircraft is decked out with advanced scientific instruments, 170 square feet of composite structures and several 3D-printed parts.

Grace Nehls

Senior Managing Editor, CompositesWorld

Composites launch to Mars

NASA’s recently launched Perseverance rover and Ingenuity helicopter are supported by numerous composite materials and structures.

Read MoreKordsa expands thermoplastic prepreg lineup

The new woven prepregs are offered with polypropylene or polyamide resin matrices in sheets up to 1.2 by 1.2 meters.

Read MoreBoron fiber: The original high-performance fiber

History and future developments for high-performance boron fiber.

Read MoreTooling, precision enable composites in satellite subsystems

Tight tolerances drive design and engineering of large-format composite component and dishes to create unique satellite structures.

Read MoreComposites in the race to space

Advanced materials use in current and upcoming NASA missions.

Read MoreGurit features core materials, adhesives, resins, molds for wind, aerospace

Gurit is featuring its offerings and expertise for wind energy, composite tooling and lightweighting applications such as aerospace, rail, healthcare and marine.

Read MoreUniversity of Bristol, NCC develop novel composite materials to assess performance in space

In-house developed matrices reinforced with carbon fiber will spend six months attached to the ISS to better understand and improve their functionality in extreme space conditions.

Grace Nehls

Senior Managing Editor, CompositesWorld

Tech Table: Adhesives

A table of aerospace structural adhesives includes collected from data provided by suppliers.

Read MoreCAMX 2019 exhibit preview: Specialty Materials

Specialty Materials Inc. is emphasizing its line of boron monofilament and prepreg materials, as well as SCS silicon carbide monofilament.

Read MoreNew Products: December 2018

CW’s roundup of new products for the composites industry – the past couple of months have seen innovations from Airtech, Cincinnati Inc., Composites Evolution, Evonik, Finepart, Granta, Gurit, Huber, Hyosung, Owens Corning, Park Aerospace, SAERTEX, Siemens, Thought3D and Victrex.

Read MorePark Aerospace's epoxy, cyanate ester resins target advanced radome applications

Park Electromechanical Corp. has introduced RadarWave, a new family of prepreg materials developed for the fabrication of advanced radome systems, principally for aerospace and defense applications.

Read MoreCAMX 2018 preview: Compotool

Compotool (Monroe, WA, US; Auckland, New Zealand) is featuring its inorganic tooling board made from specialized formulated calcium silicate materials that reportedly exhibit favorable thermal and process characteristics.

Read MoreResearchers successfully 3D print carbon fiber

Lawrence Livermore National Laboratory (LLNL) researchers claim to be the first to 3D print aerospace-grade carbon fiber.

Read MoreAxiom prepregs target pressure vessels

Axiom Materials has launched two new narrow prepreg products developed for use in pressure vessels to store compressed natural gas (CNG) and hydrogen for e-mobility applications.

Jeff Sloan

Brand Vice President, CompositesWorld & Plastics Technology, CompositesWorld

Materials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

Read MoreFirst 3D woven composite for NASA thermal protection systems

A NASA-led team develops 3D woven quartz preform, hybrid process to infuse it with cyanate ester resin (0.5% voids) and achieves TRL5 in three years to replace CF/phenolic in the Orion spacecraft’s compression pads.

Read MorePlant tour: Harris Corp., Rochester, N.Y., U.S.

High-technology telescope and space structures expertise has its roots in legacy Kodak programs.

Read MoreOuter space: The “final frontier” is exciting again!

CW contributor Dale Brosius, a composites industry consultant and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI), points to evidence that the composites industry will, once again, be the beneficiary of renewed drive for space exploration.

Read MoreFiber reinforcement forms

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

Read MoreFarnborough 2014 Airshow Report

No longer a novelty at aerospace trade events, composites nevertheless faced competition from conventional materials at this year’s event.

Read MorePerseverance rover takes one step for composites on Mars

The rover’s successful landing on Feb. 18 begins a two-year science investigation of Mars’ Jezero Crater for ancient microbial life.

Grace Nehls

Senior Managing Editor, CompositesWorld

Composites carry the Curiosity rover to a safe Mars landing

From launch to touchdown, composites performed in flight and stuck the landing!

Read MoreBMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

Read MoreThe Private Space Race

NASA passes the development torch to legacy contractors and NewSpace entrepreneurs, igniting a new competition in space transport.

Read MoreOrion re-entry system: Composites displace metal

World’s largest heat shield updates metal design with out-of-autoclave process.

Read MoreResins for the Hot Zone, Part II: BMIs, CEs, benzoxazines and phthalonitriles

Next-generation aerospace programs demand higher temperatures for structural and hot-section components, fostering advances in thermoset resin chemistry.

Read MoreSAMPE 2009 Product Showcase

Showgoers at the SAMPE 2009 Conference and Exhibiton in Baltimore, Md. found many suppliers undeterred by poor economic news.

Read More

.jpg;maxWidth=300;quality=90)