Digital Demos

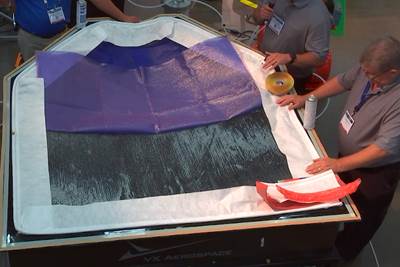

Digital Demo: Secure Vacuum Bag Seal Eliminates Single-Use Sealant Tapes in Closed Mold Process

Magnum Venus Products (MVP) has developed a reusable two-part seal for the vacuum infusion closed mold process, replacing single-use sealant tapes. (Sponsored)

WatchDigital Demo: The Advantages of Thermoplastics Technology

From stronger, longer-lasting parts to creating sustainable options for composite parts, this demo will pique your interest in this emerging technology. (Sponsored)

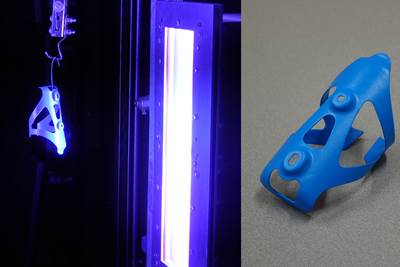

WatchDigital Demo: UV-Cured Powder Coating on Carbon Fiber

Keyland Polymer's R&D chemist will demonstrate the UV powder coating application process followed by UV curing on a carbon fiber water bottle holder. (Sponsored)

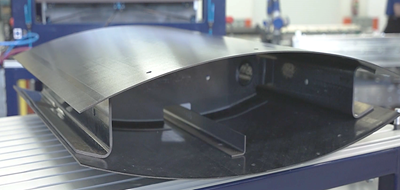

WatchDigital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

WatchMust-have capabilities in a large-format additive manufacturing machine

Thermwood’s Large-Scale Additive Manufacturing (LSAM) system comes equipped with many features that make fabrication of large fiber-reinforced polymer parts and structures fast, efficient and accurate.

WatchKVE INDUCT: Welding a torsion box demonstrator

To meet sustainability targets and market demands, the aerospace industry is searching for alternative joining methods. Automated assembly of thermoplastic composite structures by induction welding offers a solution. (Sponsored)

WatchImprove production with five-axis machines built for composites

Virtually tour (4) USA-Made 5-Axis CNC Machines designed and engineered to help companies improve profits by decreasing cycle times and improving part quality. (Sponsored)

WatchT-Link expands design and manufacturing processability for armor while providing better performance by weight

L&L Products meets a long-existing industry need with T-Link™, an advanced engineering thermoplastic adhesive hybrid resin that does not require refrigeration or special handling and – being highly customizable – can be easily and quickly consolidated into a composite structure. (Sponsored)

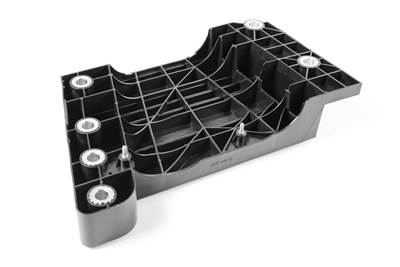

WatchContinuous Composite Systems (CCS) – enhanced strength and rigidity

With our Continuous Composite Systems (CCS) products and process, L&L Products can deliver a cost-effective, lightweight, ultra-high strength reinforcement solution that brings extensive engineering knowledge, advanced CAE modeling, and the ability for adhesive use in a variety of applications. (Sponsored)

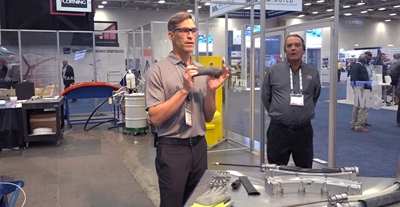

WatchConverting from hand layup to open mold spray-up process

In this Digital Demo, Sam Cruz, MVP's Senior Product Manager, talks about how to convert from hand lay-up process to spraying fiberglass and offers an overview of the benefits. (Sponsored)

Watch