Composites Design & Simulation

Designers of composite parts can choose from a huge variety of fiber reinforcements and resin systems, a situation that gives infinite design freedom but adds to composites’ complexity. Along with cost factors, knowledge of material properties is a prerequisite to satisfactory product design. The mechanical properties, orientation, and type of fibers; the properties of the resin; the fiber-to-resin ratio and behavior of the combined materials; and the intended fabrication process are all factors to consider in the design of a composite part.

Latest Design/Simulation Articles

VIEW ALLSolico software suite now includes horizontal tank module

Solico Engineering introduces the module to complete its Amphora calculation tool, made for the design of fiber-reinforced silos and tanks.

Read MoreModeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read MoreTesting to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreJetcam nesting/IoT software release focuses on enhanced computing power performance

The company cites up to 80% reduction in NC code generation time when using Jetcam Expert CAD/CAM software version 24.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreDigital workflows optimize material yields, design and productivity

CAMX 2024: TruComposites and Evolv GMP digital manufacturing solutions by Magestic Technologies drive efficiencies and precision across composites manufacturing disciplines.

Read MoreKnowledge Centers

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORELatest Design/Simulation News And Updates

CoreTech, Xnovo bring 3D imaging to Moldex3D molding software

Moldex3D users will now be able to conduct accurate 3D fiber orientation simulations using calibrated fiber parameters.

Read MoreAurora reveals latest SPRINT X-Plane design concept

An Aurora and Boeing team advances its high-speed, vertical lift concept to the preliminary design phase, which features three lift fans, a more refined composite exterior and an uncrewed cockpit.

Read MoreAnaglyph releases Laminate Tools version 5.2

Nesting, design, GUI and viewing features have been improved or added to the composites design software tool.

Read MoreNCC leads composites manufacturing phase of eXtra wing demonstrator

Key structural elements for a 6-meter section of the Airbus biomimetic wing were undertaken by NCC engineering specialists to produce 28 one-off flying parts.

Read MorePlyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

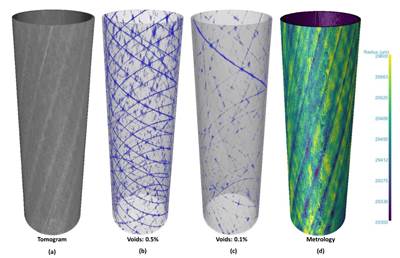

Read MoreNew Frontier Technologies launches digital twinning, high-fidelity simulation capability

3D imaging and analysis capability illustrates detailed, quality characterization and performance simulation of composites and other advanced materials that properly captures the as-manufactured component.

Read MoreFeatured Posts

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

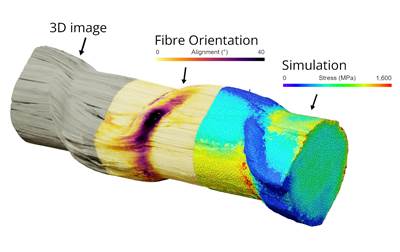

WatchMulti-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

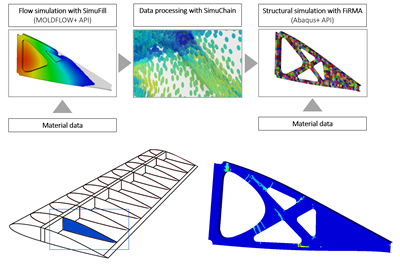

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

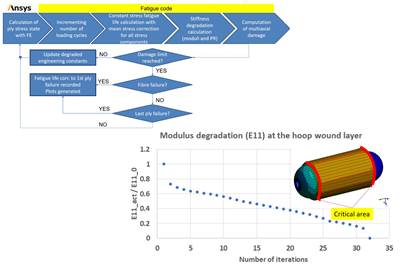

WatchNumerical tool with mean stress correction demonstrated for fatigue life estimation of thermoplastic composites

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

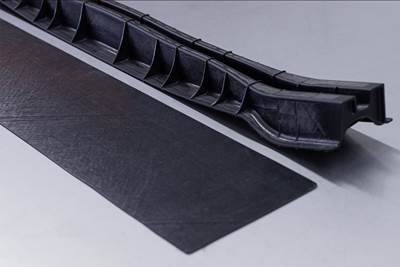

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

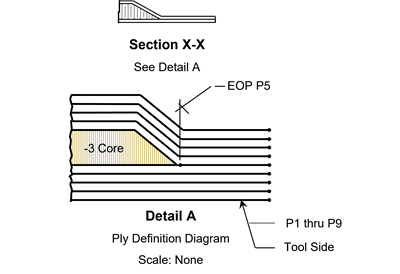

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read More

.jpg;maxWidth=300;quality=90)