Fabrics/Preforms for Composites

Composite fabrics or preforms serve as the foundation for creating composite materials, comprising carefully arranged layers of fibers or textiles before they are infused or coated with a matrix material. These fabrics or preforms come in various shapes, weaves, and orientations, allowing engineers to customize the material's properties based on specific application requirements. They play a pivotal role in determining the final characteristics of the composite, influencing factors like strength, flexibility, and weight distribution.

Latest Fabrics/Preforms Articles

VIEW ALLMoistTech Corp. introduces IR3000 moisture sensors

Near infrared (NIR) sensors deliver precision moisture control and reliable moisture analysis for natural fibers, synthetic fibers and blended fabrics.

Read MoreBiesterfeld gains composites distribution rights from Saertex

Under the new strategic distribution partnership, Biesterfeld will be the official sales partner for various Saertex material products to the German market.

Read MoreCSub delivers one-piece composite truss bridge in Norway

EPC supplier has fabricated, transported and delivered a 42-meter composite bridge intended for pedestrians and bicyclists.

Read MoreShawmut acquires Fairystone Fabrics

Shawmut Infinite’s purchase of the warp-knitting supplier supports the company’s vision for a fully integrated textile and textile composite supply chain in North America.

Read MoreCommingled yarn solutions provide flexible thermoplastic prepregs

CAMX 2024: Concordia Engineered Fibers presents customizable commingled yarn solutions, including environmentally friendly options.

Read MoreNovel woven UD fabrics are designed for versatility, reliability

CAMX 2024: Zoltek introduces PX35UD0300EPW and PX35UD0600EPW, carbon fiber fabrics providing easy handling that have the potential to meet the evolving needs of composite applications.

Read MoreKnowledge Centers

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest Fabrics/Preforms News And Updates

Ultra-light woven reinforcement fabrics enhance space-grade parts

CAMX 2024: TeXtreme is showcasing its TeXtreme 0/90 woven fabrics, demonstrated through customer Kerberos Engineering’s satellite solar array.

Read MoreStitched, needle-punched fabrics benefit open and closed molding

CAMX 2024: Vectorply Corp. displays a range of engineered reinforcements, including NCFs, needle-punched reinforcements, consumables and more, along with highlighting it technical support options.

Read MoreTextile machinery, NCFs provide sustainable processing options

CAMX 2024: Karl Mayer is returning to CAMX with a focus on fabric- and fiber-handling equipment, in addition to its application development services.

Read MoreAngeloni launches non-stitched multiaxial NCF fabric option

An adhesive grants the same stability of traditionally stitched composite fabrics, making Stratos suitable for use in a range of fibers and production processes.

Read MoreMonadnock HTAC Veil protects GFRP equipment against corrosion

Binder-free ECTFE-apertured reinforcement maintains a high resistance against chemicals and abrasion at high temperatures, extending performance and integrity of composite systems.

Read MoreChomarat expands range of composite reinforcement options

Rovicore FM core and C-Weave Stabilized woven fabrics are designed to improve the quality and performance of composite materials.

Read MoreFeatured Posts

Designing an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

WatchRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

WatchHybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

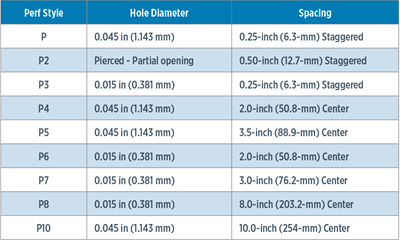

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

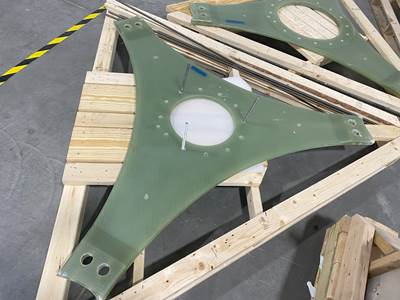

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

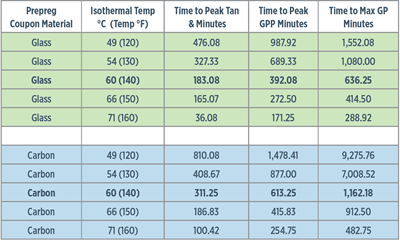

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read More

.jpg;maxWidth=300;quality=90)