Composites Use in Military & Defense

One of the main drivers of composites use in defense-related structures – such as components for fighter jets and other aircraft, weapons systems, and to some extent land- and water-based vehicles – is the high temperatures and harsh conditions in which these applications are used. Composite materials also offer high impact resistance, light weight and corrosion resistance needed for work in the field.

Latest Defense Articles

VIEW ALLFibreCoat secures up to €20 million for coatings maturation

Metal- and plastics-coated fiber innovator aims to rapidly grow radiation-, heat- and EMI-resistant material offerings for space and defense.

Read MoreCaracol, AES forge LFAM-centered partnership

AES’ LFAM services, backed by Caracol’s Heron AM 3D printing platform, target an innovation boost in aerospace- and defense-specific composite and metal applications.

Read MoreNIAR, SNC partnership to modernize USAF 747-8i aircraft

As part of the SAOC program, NIAR will replace the outdated Nightwatch aircraft, vital to U.S. Air Force operations, using its expertise in composites, 3D printing and Industry 4.0.

Read MoreSpirit sells off Fiber Materials Inc. business to Tex-Tech Industries

Purchase agreement of high-temperature materials business will be added to Tex-Tech’s specialty textiles and fabrics portfolio following customary approvals.

Read MoreBell selects Wichita for FLRAA fuselage assembly site

Supporting work will take place at several of Bell’s advanced manufacturing facilities in Texas, including Bell’s Advanced Composite Center in Fort Worth, and final assembly in Amarillo.

Read MoreGKN Aerospace revitalizes defense supply chain with C-27J nacelle deliveries

Successful engagement of more than 40 suppliers reestablishes the company’s composite and assembly manufacturing capabilities, secures business continuity for the next 5 years with Leonardo Aircraft.

Read MoreKnowledge Centers

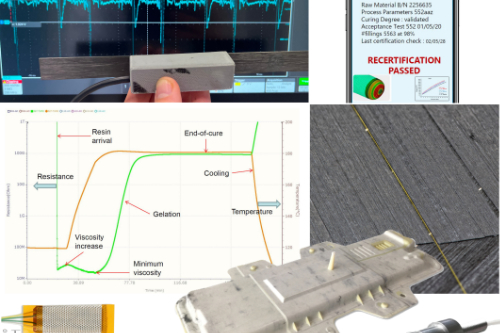

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest Defense News And Updates

Integris Composites becomes U.S. Army FLRAA armor supplier

New contract with Bell Texton Inc. will equip the Bell V-280 Valor with fit-for-purpose composite military armor.

Read MorePyromeral quality certifications support CMC compliance requirements

ITAR and JCP certifications enable aerospace and defense customers to benefit from Pyromeral’s thermal management solutions.

Read MoreTighitco receives production, spares award for CH-53K helicopter

Activities for the Sikorsky aircraft will be supported by Tighitco’s U.S. Complex Composites division from 2025-2027.

Read MoreTata Advanced Systems, Airbus inaugurate C295 final assembly line in India

Final assembly line supports program for self-reliant defense manufacturing in India, with first composite C295 roll-out targeting 2026 and ramp up of 40 aircraft by 2031.

Read MoreArris chosen by U.S. Army for study on continuous fiber insoles

Arris Composites has been selected by the U.S. Army to conduct a study regarding the use of continuous fiber composite plates in military boots.

Read MoreAurora reveals SPRINT fan-in-wing design progress

Development of uncrewed demonstrator with 45-foot wingspan, 1,000-pound payload to prove high-speed, vertical-lift, runway-independent mobility.

Read MoreFeatured Posts

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePull-wound carbon fiber poles enable lightweight, compact, rigid emergency stretcher

Based on military feedback, Epsilon Composite developed an optimized, foldable stretcher that combines telescopic pull-wound carbon fiber tubes.

WatchIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreDefense manufacturer reflects on growth, opportunity in complex composite structures

Long Island-based, four-time CW Top Shops honoree GSE Dynamics cites diversification in processes, digitalization, workforce training and more on its successes over 50+ years, and looks ahead to future growth.

Read MoreBallistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreFAQ: Defense

How are composites used in the defense market?

Composites can be used to lightweight defense aircraft and other vehicles, increasing range or allowing higher payloads.

Ultra-high temperature (UHT) composite materials can also be tailored to withstand harsh environments and high temperatures, or to be antiballistic. Research and production of ultra-high temperature (UHT) ceramic matrix composites (CMC), with melting points of 2,500°C (4,532°F) or higher, has ebbed and flowed over the years, following rising and falling demand for applications like hypersonic defense systems and space launch vehicles.

Source: Lockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Can composite materials be antiballistic?

New materials cntinue to be developed for use as bullet-proof armor for vehicles, infrastructure and equipment.

Historically, antiballistic material designers have preferred tough but expensive aramids, high-density polyethylenes and the like, passing over conventional E-glass as too brittle to have ballistic stopping power.

Proprietary additives and resin systems have enabled the development of bullet-proof fiberglass materials. 3D weaving of carbon fiber, fiberglass or other composite materials can also help to develop high-strength preforms for use as armor materials or molded panels.

.jpg;maxWidth=300;quality=90)