Composites Use in Consumer Products

The complexity and costs of design and manufacture with composite materials lend them well to structural applications like aircraft wings, boat hulls, and car bodies. However, one of the largest markets by volume for composites is consumer goods, including electronics, sporting goods, bathtubs and swimming pools, bicycles, recreational vehicles (RV) and more.

Latest Consumer Articles

VIEW ALLArris debuts consumer-driven brand for carbon fiber tech

Limited-edition products, from footwear to phone cases, will be available through Aurorra by Arris.

WatchDITF, Fiber Engineering highlight biodegradable natural fiber plant pot project

Materials and fabrication process R&D achieves low-cost, compostable plant pots made from invasive hyacinth fibers and a thermoplastic matrix processed via hot press.

Read MoreCarbitex secures capital for next phase of growth in carbon fiber plate footwear

Carbitex Inc. announces the close of a recent funding round, aiding its 2-year effort to restructure the company and expand its global market presence.

Read MoreSelf-balancing electric mobility vehicle developed by Genny Factory SA, RadiciGroup, Acerbis

The two-wheeled personal transporter was redesigned from metal to composite and plastic components to reduce weight while meeting performance standards.

Read MoreSyensqo provides PARA resin for Artiphon musical instrument

Artiphon has chosen Syensqo’s Ixef PARA fiber-filled resin in the production of Chorda, its custom handheld electronic musical instrument.

Read MoreGlass fiber-reinforced Akulon RePurposed recyclate enables Ahrend sustainable office chair

Envalior 30% glass fiber-reinforced Akulon RePurposed material helps Ahrend achieve lighter task chair with closed-loop value chain and reduced emissions.

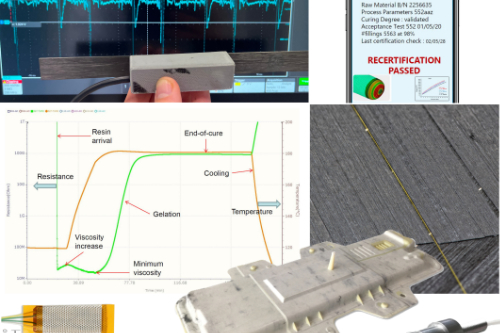

Read MoreKnowledge Centers

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORELatest Consumer News And Updates

AOC and partners achieve styrene-free composite RV roof

Indupol, Büfa and AOC brought their materials and fabrication know-how to yield a styrene-free gelcoat and RTM formulation for the manufacture of luxury vehicle roofs.

Read MoreCarbon Mobile carbon fiber powers handheld gaming platform

HyRECM technology effectively stabilizes carbon fiber’s electrical and antenna properties, enabling development of next-gen electronics, such as the Snapdragon G3x Gen 2.

Read MoreSwancor, Massload jointly develop 100% recycled bicycle bottle cage

A blend of recycled carbon fiber and PA6 pellets, the bicycle component will be commercialized in Q1 2024.

Read MoreHyfer Objects furniture incorporates Sulapac wood composites

High-end design furniture is 3D printed from bio-based, eco-friendly materials for aesthetic and sustainable home product options.

Read MoreRein4ced, Dieffenbacher automate large-scale production of CFRP bike frames

A synergistic alliance combining Dieffenbacher’s production automation with Rein4ced’s hybrid Feather composite led to fully automated bike frame production line, which will be expanded to other composite products.

Read MoreAcciona Energía, El Ganso develop shoes made with recycled wind blade materials

Limited-edition sneakers feature soles composed of micronized dismantled wind blades from a wind farm in Navarra, Spain.

Read MoreFeatured Posts

Repurposing wind blades as functional community art pieces

Ohio-based Canvus Inc. upcycles fiberglass wind blades, car tires and post-consumer plastics to create outdoor furniture that amplifies sustainability messages in community spaces.

WatchPlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreRunning shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreLighter, stronger, faster bionic hand aided by composites design

Psyonic’s touch-sensing prosthetic hand leverages bionic technology, 3D printing and a carbon fiber composite exterior for light weight, high strength and high-tech functionality.

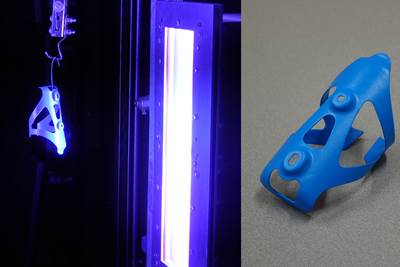

WatchDigital Demo: UV-Cured Powder Coating on Carbon Fiber

Keyland Polymer's R&D chemist will demonstrate the UV powder coating application process followed by UV curing on a carbon fiber water bottle holder. (Sponsored)

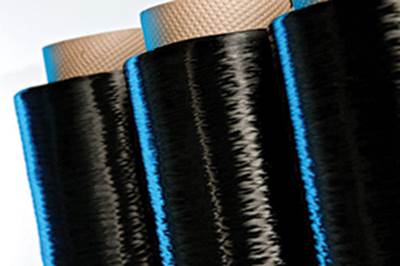

WatchMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreFAQ: Consumer

How are composites used in sporting goods?

Carbon fiber composite bicycle frames are the highest-profile application of composites in sporting goods – but they have also long been used in high-performance fishing rods, tennis rackets, skis, surfboards and more. Protective equipment such as helmets, or high-performance athletic shoes, can also be made with composite materials.

How are composites used in consumer electronics?

Composites are often used under the cover of consumer electronics, such as for components in circuit boards. Composites have also been trialed for lightweight, high-performance laptop and phone covers and other applications.

How are carbon fiber composite bikes manufactured?

Today, many carbon fiber composite bike frames are fabricated and shipped from fabricators in Asian countries, largely incorporating labor-intensive hand layup processes with carbon fiber-reinforced epoxy prepreg. Efforts are being made to develop more bicycle manufacturing in the U.S. and Europe, including more automated processes and thermoplastic materials, or even 3D printing.

.jpg;maxWidth=300;quality=90)