Thermoplastics

Thermoplastics play a pivotal role in composite materials by serving as the matrix phase that binds reinforcements together. Unlike thermoset resins, thermoplastics possess the ability to soften and reform when heated, allowing for reshaping and recycling. They offer unique advantages such as high toughness, chemical resistance, and easy processing, making them versatile in various industries like aerospace, automotive, and consumer goods. Composites using thermoplastic matrices exhibit exceptional damage tolerance and are sought after for their potential in complex manufacturing processes like injection molding, enabling efficient production of intricate and high-performance parts.

Latest Thermoplastics Articles

VIEW ALLDITF oriented rCF tapes target virgin fiber CFRP substitution

Infinity project developed highly oriented rCF/PA6 tapes with 88% the tensile strength, modulus of a virgin CFRP product and 49-66% reduction in global warming potential.

Read MoreProving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Read MoreCorebon, Composite Braiding partner to enhance TPC manufacturing

Collaboration aims to overcome production limitations with tubular thermoplastic composites (TPC) by using induction-heated tooling and high-quality commingled braids.

Read MoreToray Advanced Composites expands continuous fiber TPC capacity, capabilities

Assets, technology and IP acquisition of Colorado-based Gordon Plastics will enhance Toray’s product portfolio, growing its ability to support emerging markets in thermoplastic composites.

Read MoreKraussMaffei expands composites, plastics capabilities at Brighton, Michigan facility

The site recently installed a powerPrint large-format AM system, thermoforming machine and more to serve customers in North America.

Read MoreRoboze supports F1 composite brake cooling duct manufacture

Carbon fiber-reinforced PEEK composites, 3D printing services improve production time and costs of complex motorsport parts for Visa Cash App RB F1 team.

Read MoreKnowledge Centers

During CW Tech Days: Thermoplastics for Large Structures, experts explored the materials and processing technologies that are enabling the transition to large-part manufacturing.

LEARN MORE

Closed mold processes offer many advantages over open molding. This knowledge center details the basics of closed mold methods and the products and tools essential to producing a part correctly.

LEARN MORELatest Thermoplastics News And Updates

DITF, Fiber Engineering highlight biodegradable natural fiber plant pot project

Materials and fabrication process R&D achieves low-cost, compostable plant pots made from invasive hyacinth fibers and a thermoplastic matrix processed via hot press.

Read MoreECORES WIND builds on wind blade circularity initiatives

Latest Horizon Europe project seeks to introduce innovative circular resins combined with advanced disassembly strategies, enabling cost-effective blade decommissioning and material reuse.

Read MoreVictrex offers commercial availability of LMPAEK granules, powders

Elevated performance and process efficiency for composites and additive manufacturing processes is demonstrated through the thermoplastic polymers.

Read MoreEnvalior launches Pocan PBT compounds range with bio-based BDO

Used cooking oil is used as a base material for the PBT precursor and certified under ISCC PLUS. Recycled fiberglass content can be added for additional carbon footprint reduction.

Read MoreNational Manufacturing Group unveils C3 Molding

National Manufacturing Group features its C3 Molding process for FRP molding, offering the surface cosmetics of thermoplastics, the versatility and strength of fiberglass and compression molding cycle times.

Read MoreAsahi Kasei, Aquafil develop 3D printing material combining cellulose nanofiber, recycled PA6

Available as a pellet or filament, the material is said to exhibit formability and strength properties suitable for automotive and aerospace applications.

Read MoreFeatured Posts

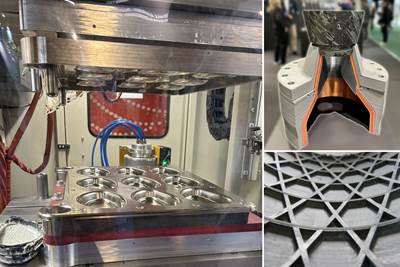

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

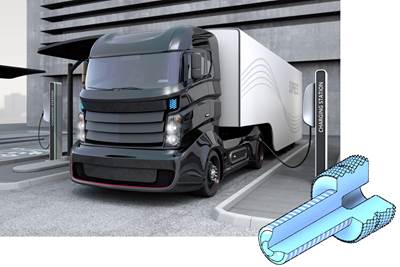

WatchCreating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

WatchFrom the CW Archives: I see thermoplastics in your future

Thermoplastics are evolving quickly into larger structures and clearly will have a significant role to play in the next commercial aircraft program — whenever that’s announced. This edition of “From the CW Archives” looks back on a thermoplastics pioneer.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

WatchPlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Watch

.jpg;maxWidth=300;quality=90)