Composites Use in Wind/Energy Markets

The wind energy market has long been considered the world’s largest market, by volume, for glass fiber-reinforced polymer (GFRP) composites — and increasingly, carbon fiber composites — as larger turbines and longer wind blades are developed, requiring higher performance, lighter weight materials. The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

Latest Wind/Energy Articles

VIEW ALLVestas to repurpose Isle of Wight facility for U.K. onshore blades

Transition from offshore to onshore wind blade production will support the U.K.’s focus on building domestic supply chains, increasing demand.

Read MoreORNL demonstrates lightning strike protection tech for composites

Researchers, led by Vipin Kumar, developed a low-cost, recyclable carbon fiber wind turbine blade tip that showed resilience to high-voltage lightning strikes, with more innovations in store.

Read MoreSwedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreORPC Ireland, Queen’s begin X-Flow project for hydrokinetic turbine testing

Deployment of CFRP turbine technology to Strangford Lough will provide insight into blade and rotor performance, predictive maintenance and grid-scale benefits of tidal energy using real tide conditions.

Read MoreGurit announces strategic alignment to preserve wind leadership, accelerate growth in other markets

While expected wind business revenue did not materialize for Q3 2024, Gurit is actively implementing measures to diversify its portfolio and position it for a wind sale increase in 2025.

Read MoreECORES WIND builds on wind blade circularity initiatives

Latest Horizon Europe project seeks to introduce innovative circular resins combined with advanced disassembly strategies, enabling cost-effective blade decommissioning and material reuse.

Read MoreKnowledge Centers

This CW Tech Days event will explore the technologies, materials, and strategies that can help composites manufacturers become more sustainable.

LEARN MORE

Review the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

LEARN MORE

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORELatest Wind/Energy News And Updates

MingYang completes 20-MW offshore wind turbine installation

The MySE18.X-20MW, located in China, becomes the largest single-capacity offshore wind turbine on the market.

Read MoreBlueWind secures contract with GE Vernova to manufacture wind turbine nacelle covers

With more than 2,000 2X nacelle covers manufactured, the company expands its supply with the WT20 model

Read MoreCorPower Ocean secures funding to commercialize wave energy

CorPower Ocean announces significant investment in its wave energy technology that converts its motion into electricity via a filament-wound fiberglass buoy design.

Read MoreNCC, BCI, Vestas collaborate to enhance wind blade technology development

NCC, BCI and Vestas have established the U.K. Offshore Wind Industrial Growth Plan, aiming to accelerate wind blade technology development and lower energy costs.

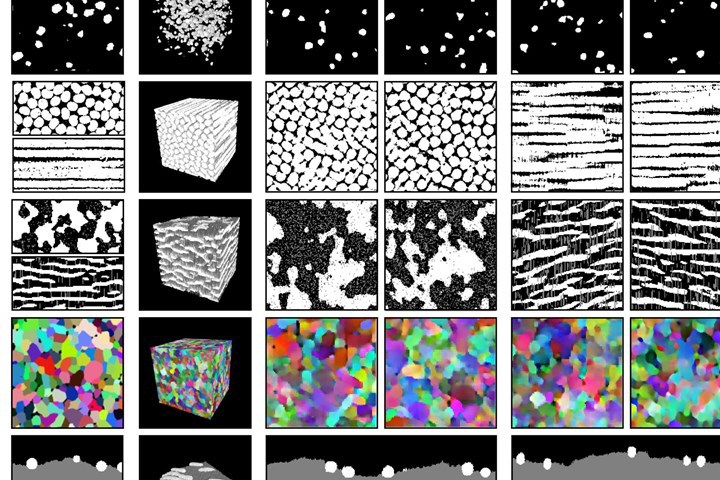

Read MoreZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.

Read MoreBelzona coatings expand composite leading edge protection, lifespan

Belzona highlights the use of Belzona 5711 and 5721 to extend the lifespan of 42 wind turbine blades in Denmark facing severe erosion.

Read MoreFeatured Posts

Composites reinvent energy

Celebrating National Composites Week 2024, CW looks at how composites are being used to provide the next generation of energy.

WatchComposites reinvent infrastructure

Celebrating National Composites Week, CW shares ways in which composites continue to evolve the way we approach infrastructure projects.

Read MoreAchieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

WatchRepurposing wind blades as functional community art pieces

Ohio-based Canvus Inc. upcycles fiberglass wind blades, car tires and post-consumer plastics to create outdoor furniture that amplifies sustainability messages in community spaces.

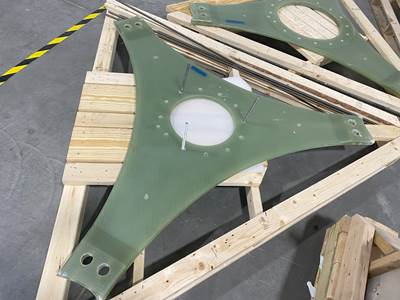

WatchRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

WatchFAQ: Wind/Energy

What are wind turbine blades made from?

- The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

- Source: Composites end markets: Renewable energy

What energy applications are composites used for?

In renewable energy, fiberglass composites are used, most prominently, to build wind turbine blades and nacelles. Carbon fiber composites are also used to build wind blade spar caps. Hydroelectric turbines, tidal energy turbines and other forms of renewable energy have also made use of composites.

In oil and gas, composites have long been used as a corrosion-resistant metal alternative for a number of applications, including components for protecting wellheads, manifolds and other equipment related to subsea processing, and offshore pipelines themselves.

What happens to wind blades at the end of their lifespan?

As wind energy ramps up, recycling of composite wind blades at their end of life (EOL) – as well as composites and plastics recycling in general – continues to be a topic of concern.

More than 80% of a wind turbine itself is typically metallic and recyclable, but the increasingly long, high-performance composite blades pose more of a challenge.

Efforts include:

-

-

- Near-term: Ramping up existing recycling methods like mechanical chopping up blades or repurposing entire blades for other uses

- Medium-term: Developing more efficient methods such as chemical recycling (solvolysis) for reclaiming the original fibers from EOL blades for reuse

- Long-term: Designing and manufacturing wind blades with sustainable/recyclable materials

-

.jpg;maxWidth=300;quality=90)